Electrical failures during high-voltage events cost industries millions annually, yet many professionals struggle to choose between impulse voltage and surge voltage testing. Without understanding these critical testing differences, you risk equipment damage, safety hazards, and costly production downtime that could have been prevented. This comprehensive guide clarifies the distinction between impulse and surge voltage testing, helping you select the right method for optimal equipment protection and compliance.

Before diving into the specific differences, it’s essential to grasp why high voltage testing plays a crucial role in electrical equipment validation and quality assurance.

High-voltage testing evaluates insulation integrity, identifies potential failure points, and ensures equipment can withstand electrical stresses encountered during operation. Both impulse and surge voltage testing fall under this umbrella, yet they serve distinctly different purposes and follow unique methodologies.

Electrical equipment operates in increasingly demanding environments where:

Understanding which testing method addresses specific failure modes determines the reliability and longevity of your electrical assets. At Vivid Metrawatt Global, we specialize in providing advanced testing solutions that meet international standards and industry best practices.

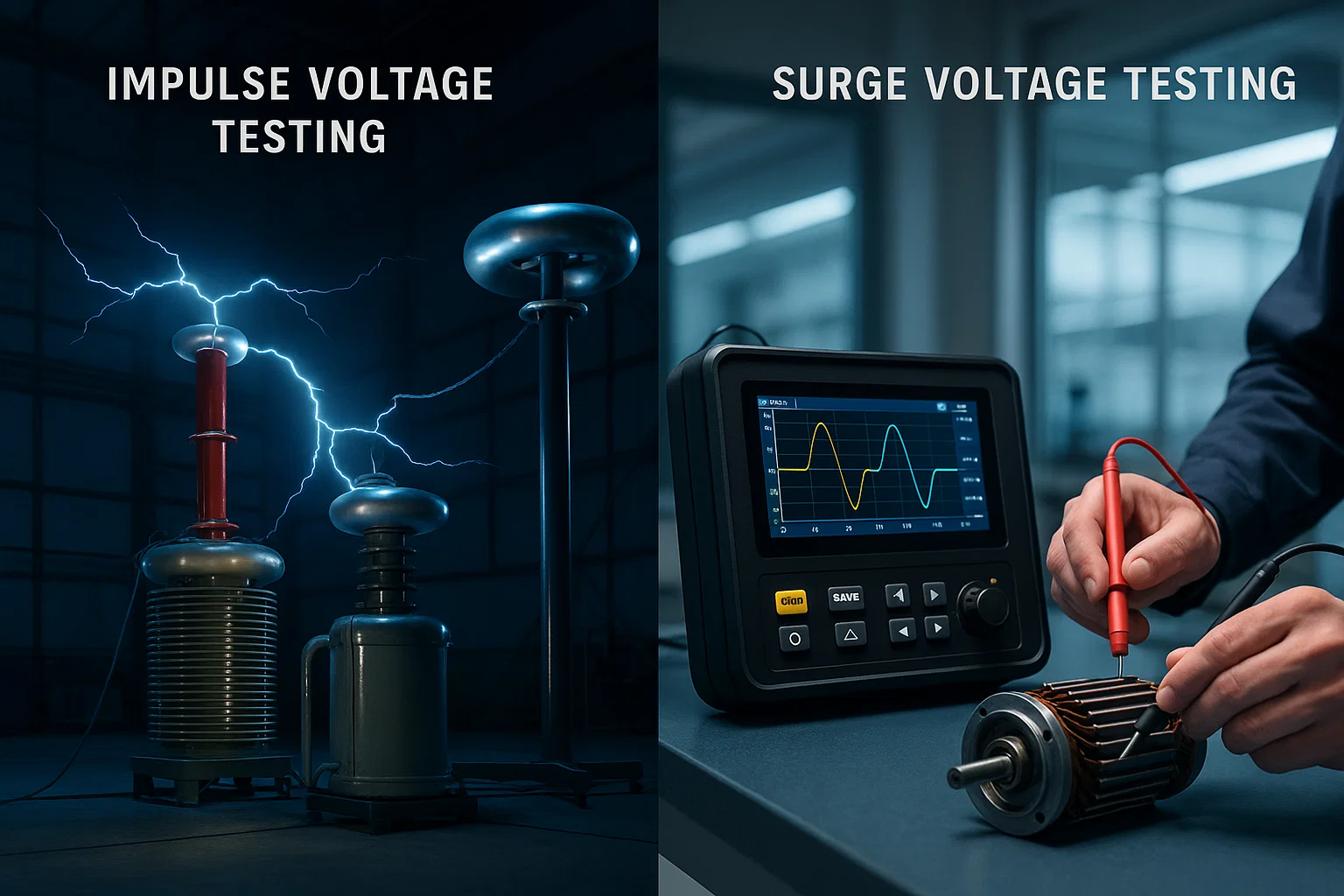

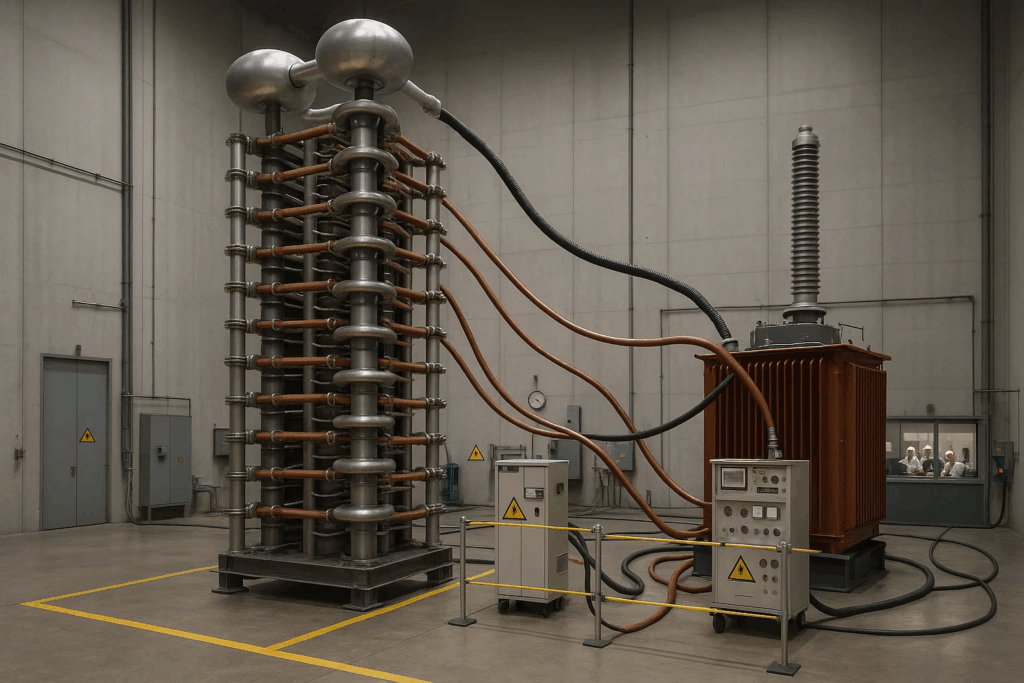

Impulse voltage testing simulates external transient overvoltages—particularly lightning strikes and switching surges—that equipment may encounter during its operational lifetime.

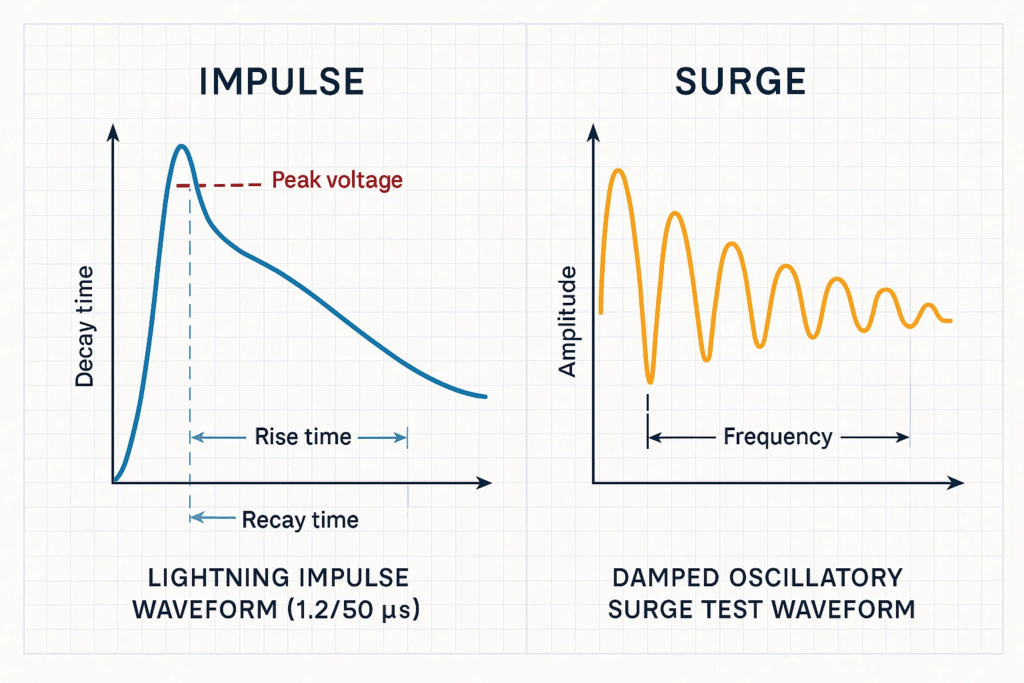

Voltage Waveform: Impulse testing uses standardized waveforms defined by rise time and decay time:

Test Objective: The primary goal is verifying that insulation systems can withstand brief, high-magnitude voltage spikes without breakdown or degradation. Understanding how surge generators work provides deeper insight into the mechanisms behind these voltage generation systems.

Voltage Levels: Impulse tests typically apply voltages several times higher than normal operating levels—often reaching hundreds of kilovolts for power equipment.

Impulse testing is mandatory for:

The impulse voltage testing process follows these steps:

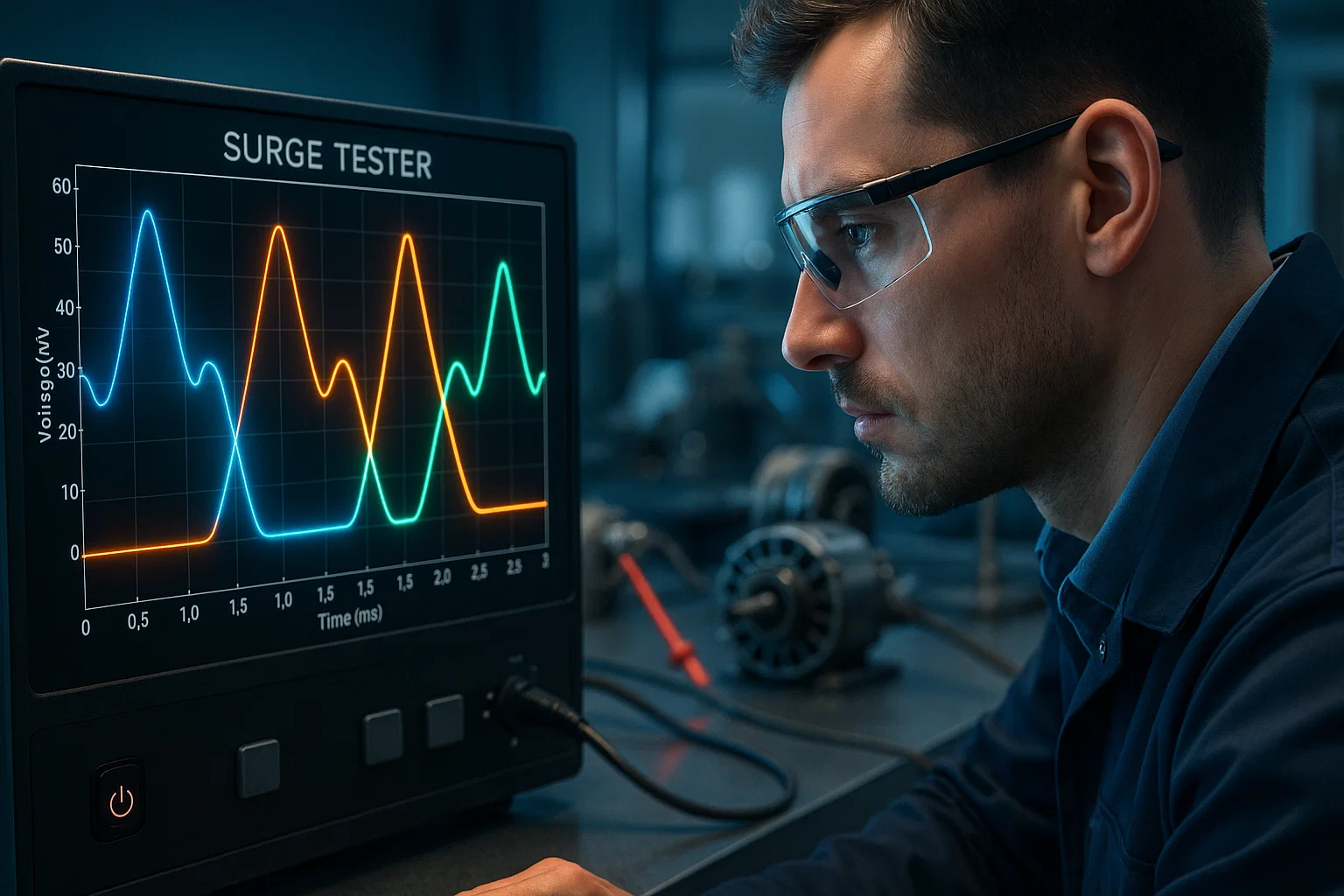

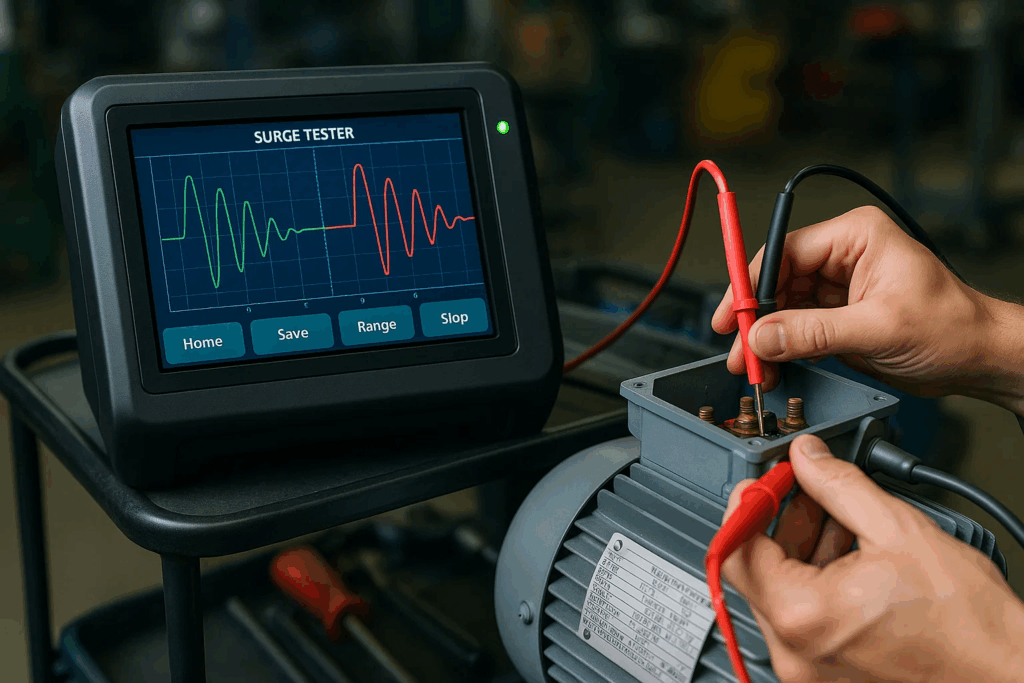

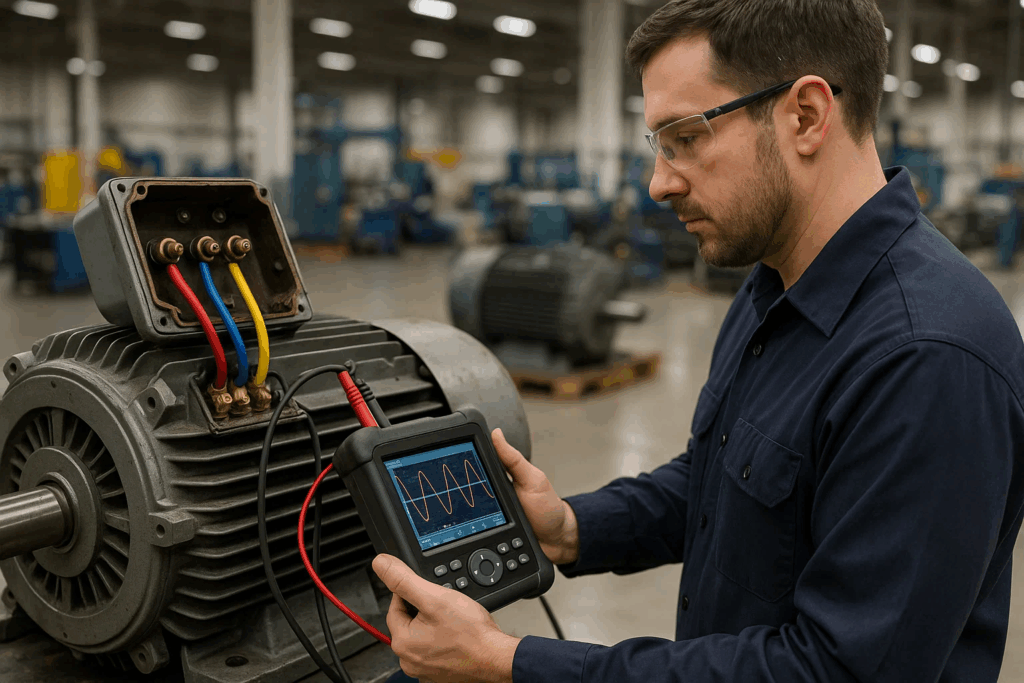

Surge voltage testing, commonly known as surge testing, focuses on detecting internal insulation defects in motor windings, transformer coils, and similar inductive components.

Voltage Waveform: Surge testing applies damped oscillatory waveforms that generate repetitive voltage stresses throughout the winding structure.

Test Objective: Rather than simulating external events, surge testing identifies turn-to-turn, coil-to-coil, and phase-to-phase insulation weaknesses that could lead to premature failure. Recognizing motor winding failure signs early can prevent catastrophic equipment breakdowns.

Voltage Levels: Test voltages typically range from 2 to 4 times the rated voltage—significantly lower than impulse testing but sufficient to stress insulation defects.

Surge testing proves invaluable for:

This method excels during preventive maintenance, quality control, and post-repair verification to ensure winding integrity. For comprehensive guidance, explore how to test motor windings using industry-standard techniques.

Modern surge testers employ sophisticated comparison techniques:

Key Advantage: Surge testing detects incipient failures before they cause catastrophic breakdowns, enabling proactive maintenance strategies that enhance motor reliability and efficiency.

Understanding the difference between impulse voltage and surge voltage testing is critical for proper equipment validation. Here’s a comprehensive comparison:

| Impulse Voltage Testing | Surge Voltage Testing |

|---|---|

| Simulates external overvoltage events (lightning, switching) | Detects internal insulation defects in windings |

| Validates design margins against transient stresses | Identifies manufacturing or service-induced faults |

Impulse Testing:

Surge Testing:

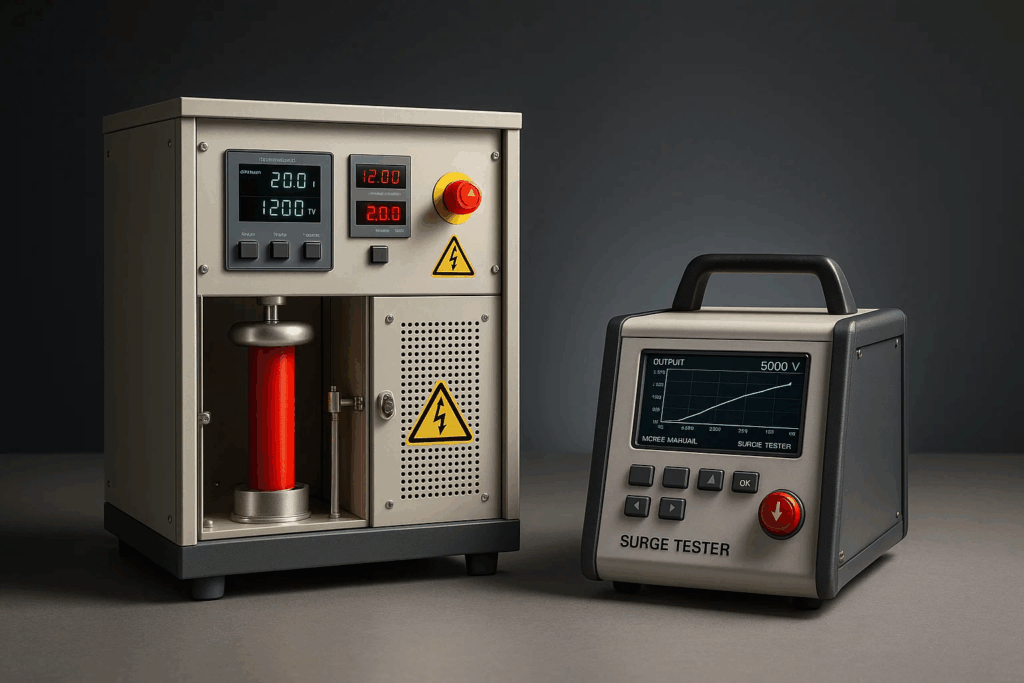

Impulse Testing Equipment:

Surge Testing Equipment:

Learn more about choosing the right surge tester for your needs to optimize your testing investment.

Impulse Testing Standards:

Surge Testing Standards:

Impulse Testing Identifies:

Surge Testing Identifies:

Understanding surge tester insulation failures helps technicians interpret test results accurately and take corrective action.

Impulse Testing: Performed primarily during:

Surge Testing: Conducted routinely for:

Selecting the appropriate testing method depends on your specific objectives, equipment type, and operational context.

✓ Validating new equipment designs to ensure compliance with lightning and switching surge withstand requirements

✓ Qualifying insulation systems for high-voltage transmission and distribution components

✓ Commissioning power transformers and other critical substation equipment

✓ Investigating external insulation failures related to lightning or switching events

✓ Meeting regulatory requirements for utility-grade equipment certification

✓ Inspecting motor windings before and after rewinding or repair

✓ Implementing predictive maintenance programs for rotating machinery

✓ Conducting quality control during manufacturing of wound components

✓ Diagnosing suspected winding failures without equipment disassembly

✓ Comparing new vs aged equipment to assess insulation deterioration

For specialized applications, consider how to test armature using a surge tester for rotating machinery diagnostics.

Many comprehensive testing programs incorporate both methods:

For example, a transformer manufacturer might use impulse testing to certify the design meets standards, while using surge testing during production to catch manufacturing defects in winding construction.

Marx Generator Configuration: Most impulse generators use Marx circuits that charge capacitors in parallel and discharge them in series, achieving voltage multiplication. Key specifications include:

Measurement Systems:

Modern digital surge testers offer sophisticated capabilities:

Key Features:

Voltage Range: Typical surge testers output 500V to 10kV, adjustable based on equipment under test.

When evaluating surge tester vs hipot tester options, remember that surge testing provides dynamic winding analysis, while hipot testing validates ground wall insulation integrity—both serve complementary purposes. For deeper technical understanding, review what is hipot in digital surge tester functionality.

Regular maintenance ensures testing accuracy and reliability. Discover how to maintain and calibrate your digital surge tester to maximize equipment lifespan and measurement precision.

Scenario: A utility company installed a 230kV/33kV, 150 MVA power transformer.

Testing Approach:

Outcome: The comprehensive testing strategy prevented a potential $2M failure and avoided extended outage impacts on 50,000 customers.

Scenario: A chemical processing facility experienced recurring motor failures costing $150K annually.

Testing Approach:

Outcome: Unplanned downtime reduced by 75%, saving $400K over two years while extending motor service life. The facility now enjoys the comprehensive benefits of using surge testers in their maintenance program.

Scenario: A wind turbine manufacturer developed a new 5 MW generator design.

Testing Approach:

Outcome: Achieved 99.8% first-pass quality rate and met stringent offshore wind certification requirements.

❌ Inadequate Grounding: Poor grounding systems can skew measurement results and create safety hazards. Always verify ground impedance before testing.

❌ Wrong Waveform Selection: Using lightning impulse waveforms for equipment designed for switching surges (or vice versa) leads to invalid test results.

❌ Insufficient Safety Margins: Applying voltages too close to breakdown thresholds during qualification testing risks damaging expensive equipment.

❌ Improper Voltage Selection: Testing at excessively high voltages can damage good windings, while too-low voltages may miss defects.

❌ Ignoring Temperature Effects: Winding temperature significantly affects surge test results. Compare tests performed at similar thermal conditions.

❌ Misinterpreting Waveforms: Without proper training, technicians may misread normal variations as faults or overlook genuine problems.

Pro Tip: Leverage resources on troubleshooting electrical testing errors and troubleshooting common surge tester errors to refine your testing procedures and avoid common pitfalls.

Machine learning algorithms now analyze surge test waveforms to:

Emerging technologies are miniaturizing impulse test equipment, enabling field deployment for on-site verification previously requiring laboratory facilities.

Continuous online surge monitoring systems detect winding degradation in real-time, transitioning from periodic testing to permanent surveillance for critical assets.

The difference between impulse voltage and surge voltage testing ultimately comes down to what you’re testing for and when you’re testing it.

Impulse voltage testing serves as your shield against external threats—lightning strikes and switching transients that could devastate high-voltage equipment. It’s the gold standard for design validation and compliance verification.

Surge voltage testing acts as your diagnostic tool for internal integrity—catching manufacturing defects and insulation deterioration before they cause unexpected failures. It’s essential for quality control and predictive maintenance.

Modern testing strategies don’t choose between them; they leverage both methods strategically to ensure comprehensive equipment protection, regulatory compliance, and operational reliability.

By understanding these fundamental differences, you can build robust testing programs that protect your electrical assets, minimize downtime, and deliver long-term value to your organization. For advanced testing solutions and expert guidance, visit Vivid Metrawatt Global to explore our comprehensive range of electrical testing equipment.

No. Surge testing evaluates internal winding insulation, while impulse testing validates external insulation against transient overvoltages. They address different failure modes and aren’t interchangeable. Understanding the difference between megger and surge test for windings also helps clarify these distinctions.

For critical motors, quarterly testing is recommended. Non-critical equipment may require annual or biennial testing based on risk assessment and operating conditions.

When performed correctly according to standards, impulse testing is non-destructive. However, equipment with pre-existing weaknesses may fail during testing—which is precisely the point of qualification testing.

Generally, 2-3 times the rated voltage for new equipment, and 1.5-2 times for equipment in service. Always consult manufacturer guidelines and applicable standards.

Impulse testing on motors is uncommon except for large machines used in critical applications. Surge testing is the preferred method for routine motor winding evaluation.

North American standards (IEEE, ANSI) and European standards (IEC) have converged significantly, though some variations exist in test voltage levels and waveform specifications. Most modern equipment complies with both.