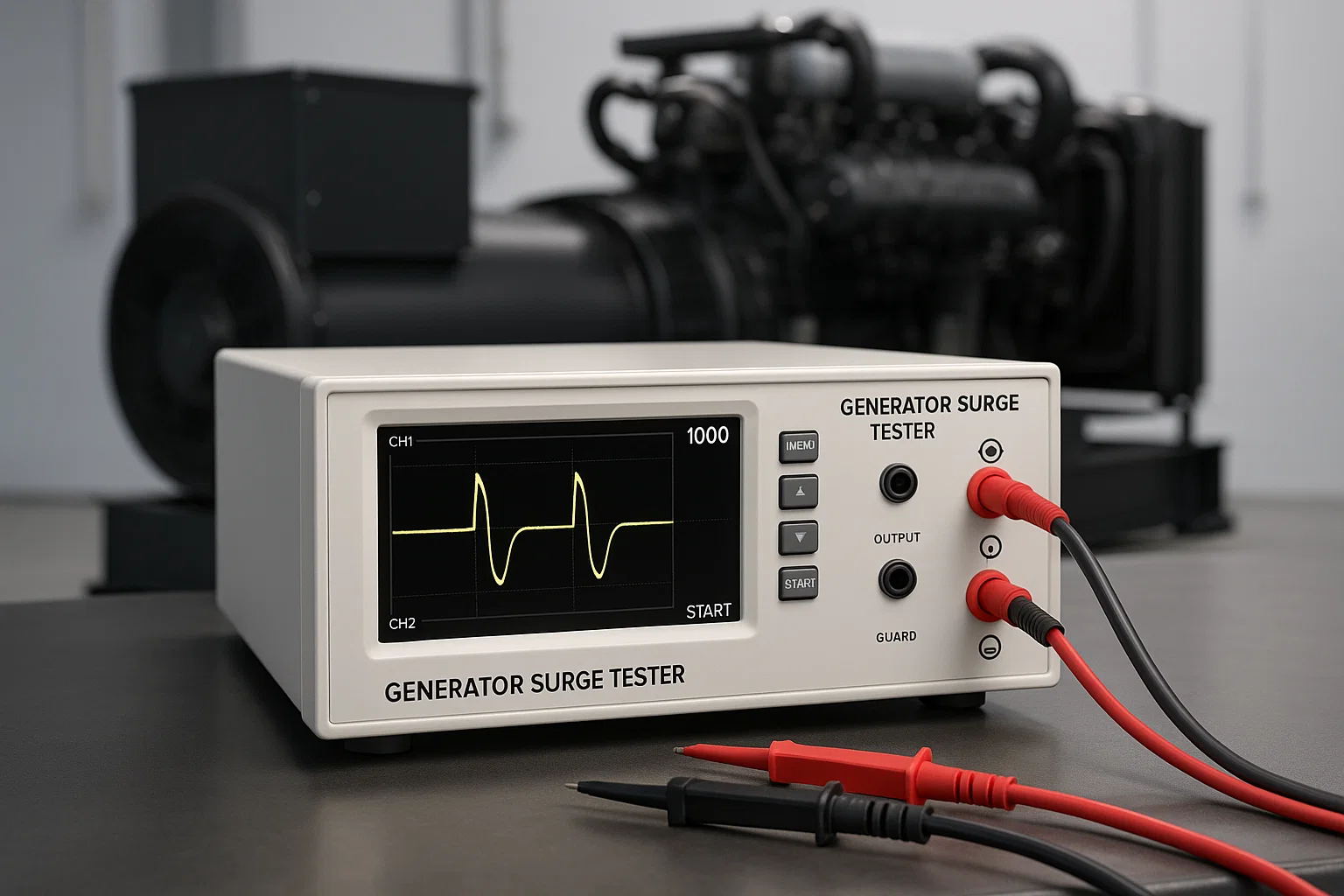

A generator surge tester is a sophisticated diagnostic instrument designed to evaluate the integrity of electrical windings in generators, motors, transformers, and other rotating electrical machinery. This precision testing equipment applies controlled high-voltage impulses to winding insulation systems, revealing defects that conventional testing methods often miss.

Unlike standard multimeters or insulation resistance testers, generator surge testers employ impulse waveform technology to simulate real-world electrical stress conditions. The equipment identifies turn-to-turn insulation failures, phase-to-phase weaknesses, and grounding issues that could lead to unexpected equipment failures.

Traditional motor winding testing methods measure resistance, continuity, or insulation resistance at relatively low voltages. These approaches provide valuable baseline data but cannot detect subtle defects in winding insulation layers. Surge testing, conversely, applies voltage levels closer to operational stress conditions, exposing vulnerabilities before they compromise your equipment.

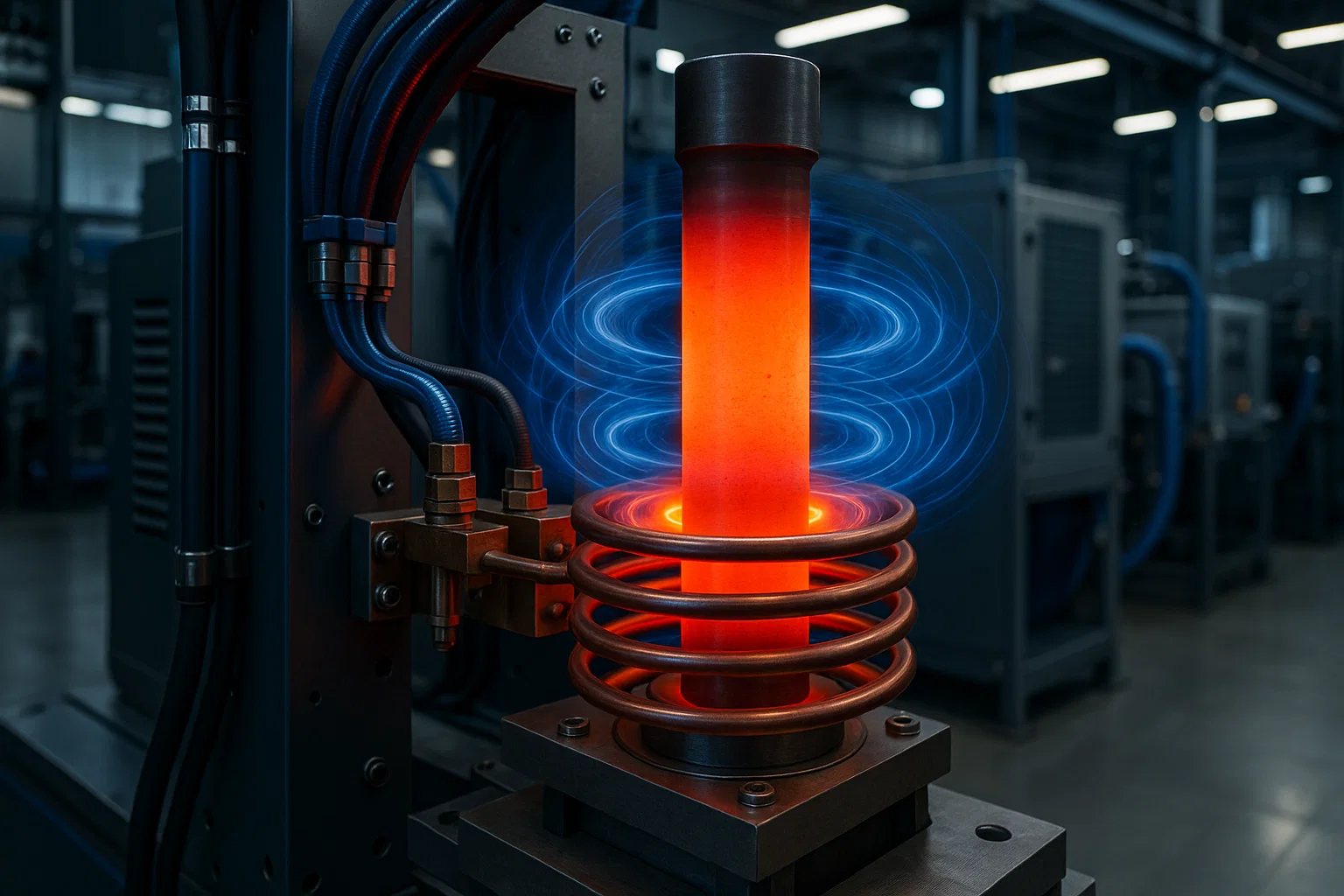

The technology operates on fundamental electromagnetic principles, sending precisely controlled voltage pulses through winding systems and analyzing the resulting waveform signatures. Any deviation from expected patterns indicates potential insulation degradation, mismatched coils, or manufacturing defects.

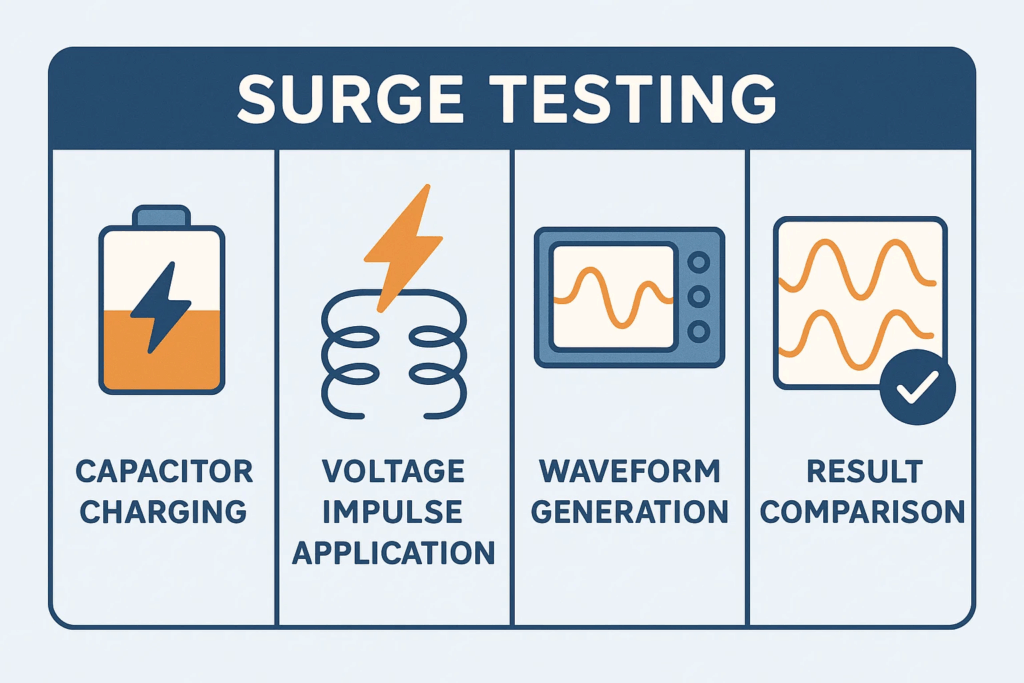

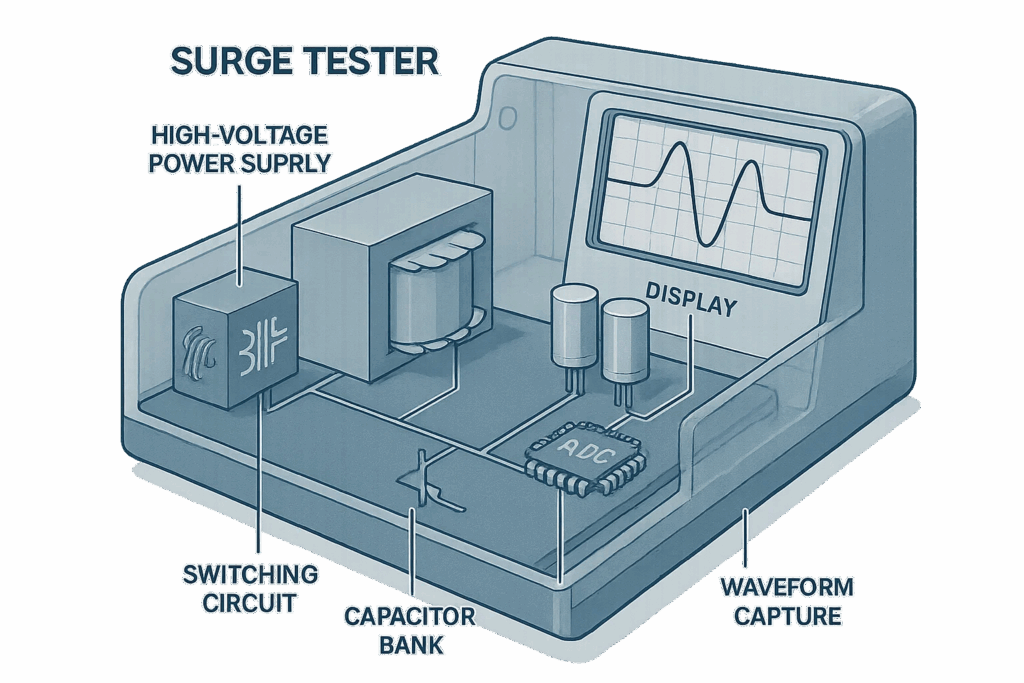

Generator surge testers function by storing electrical energy in a capacitor bank and rapidly discharging it through the equipment under test. This process creates a high-voltage impulse that stresses the insulation system in a controlled, non-destructive manner.

Capacitor Charging Phase: The tester charges internal capacitors to a predetermined voltage level, typically ranging from 200V to several kilovolts depending on the application and equipment specifications.

Impulse Discharge: When triggered, the stored energy discharges through the generator windings in microseconds, creating a damped oscillating waveform. This rapid voltage rise replicates the electrical stress experienced during motor starting, voltage transients, or switching operations.

Waveform Capture and Analysis: Advanced digital surge testers capture the resulting voltage and current waveforms with high-speed sampling rates. The equipment compares these signatures against reference patterns or between identical phases.

The fundamental principle relies on electromagnetic induction and capacitive-inductive energy transfer. When voltage surges through a healthy winding, it produces a characteristic oscillating pattern determined by the winding’s inductance and capacitance. Understanding how surge generators work provides deeper insight into this sophisticated testing methodology.

Damaged insulation alters these electrical characteristics, causing waveform distortions, damping changes, or frequency shifts that experienced technicians—or modern automated analysis software—can readily identify.

Modern generator surge testers integrate multiple sophisticated subsystems to deliver accurate, repeatable results:

Generates the required test voltages while maintaining precise control over amplitude and rise time. Quality power supplies ensure consistent testing conditions across multiple measurements.

Stores electrical energy for discharge during testing. Capacitor selection impacts pulse duration, energy delivery, and the tester’s ability to evaluate different equipment sizes.

Controls the precise timing of capacitor discharge, ensuring repeatable test conditions. Modern solid-state switches offer microsecond-level precision and extended operational lifespans.

High-speed analog-to-digital converters capture voltage and current signatures with sampling rates exceeding several megahertz, preserving critical waveform details essential for accurate analysis.

Contemporary testers feature intuitive interfaces displaying waveforms, trend data, and pass/fail indicators. Advanced models incorporate artificial intelligence algorithms for automated defect detection.

Premium generator surge testers incorporate comprehensive safety systems including:

Different testing methodologies serve distinct diagnostic purposes:

This approach compares waveforms between identical phases or coils within the same generator. By overlaying the signatures, technicians quickly identify discrepancies indicating insulation problems or manufacturing inconsistencies. Comparative testing excels at detecting turn-to-turn shorts and coil mismatches.

Gradually increasing test voltage from low levels to rated values while monitoring waveform changes helps pinpoint the voltage threshold at which insulation begins to fail. This methodology provides valuable data for assessing remaining insulation life and establishing preventive maintenance schedules.

Applying multiple surge impulses and analyzing consistency between successive tests reveals progressive insulation degradation. Changes in waveform characteristics across repeated tests often indicate moisture contamination, thermal damage, or mechanical stress.

Industry standards including IEEE, IEC, and NEMA specify testing protocols for different equipment types. Compliance testing follows these established procedures, ensuring results meet regulatory requirements and manufacturer specifications. Understanding high voltage testing standards ensures proper implementation.

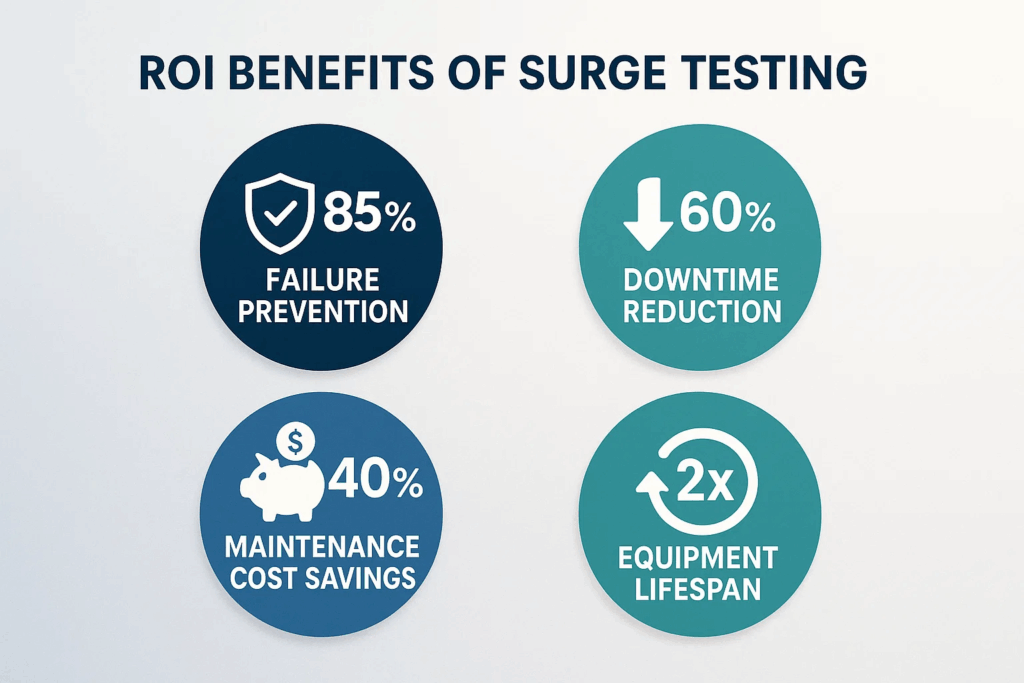

Implementing surge testing as part of your electrical maintenance program delivers substantial operational and financial advantages:

Early Fault Detection: Identifies insulation weaknesses months or years before failure occurs, enabling planned maintenance during scheduled downtime rather than emergency repairs during peak production periods.

Reduced Downtime: Predictive maintenance based on surge testing data prevents unexpected equipment failures that could halt operations for extended periods while awaiting parts or specialized repair services.

Extended Equipment Lifespan: By catching problems early and addressing them before secondary damage occurs, surge testing helps generators achieve—and often exceed—their designed operational lifespans.

Cost Savings: While the initial investment in quality testing equipment requires capital allocation, the return materializes through avoided catastrophic failures, optimized maintenance schedules, and improved asset reliability. The benefits of using surge testers extend far beyond simple fault detection.

Quality Assurance: For manufacturers, surge testing validates production quality before equipment ships, reducing warranty claims and protecting brand reputation. Service providers use testing to certify repair quality and document restoration to original specifications.

Enhanced Safety: Preventing insulation failures protects personnel from electrical hazards while safeguarding adjacent equipment from damage caused by electrical faults, arc flash events, or cascading failures.

Compliance Documentation: Many industries require documented evidence of electrical testing for insurance, regulatory compliance, or contractual obligations. Modern surge testers generate comprehensive reports satisfying these requirements.

Generator surge testers serve critical functions across diverse industrial sectors:

Utility-scale generators, backup power systems, and renewable energy installations rely on surge testing for commissioning verification and ongoing maintenance. Testing confirms insulation integrity after installation, repairs, or following electrical events.

Industrial facilities depend on reliable electrical systems driving production machinery. Regular surge testing of generator sets, large motors, and transformers minimizes production interruptions while optimizing maintenance resource allocation. Exploring various applications of digital surge testers reveals their versatility.

Locomotive traction motors, auxiliary generators, and power conversion equipment undergo harsh operating conditions. Surge testing validates repairs and monitors equipment health in demanding railway environments, supporting operational reliability. Specialized induction heating solutions for railways complement comprehensive electrical maintenance programs.

Ship generators, propulsion motors, and offshore platform power systems operate in corrosive, high-humidity environments accelerating insulation degradation. Surge testing adapted for maritime applications helps prevent failures in remote locations where repairs prove extraordinarily expensive.

Large commercial HVAC systems incorporate substantial motors and generators. Preventive surge testing ensures climate control reliability in data centers, hospitals, and commercial buildings where environmental control proves mission-critical. Understanding surge testing for HVAC applications optimizes building system maintenance.

Understanding how surge testing compares with alternative diagnostic approaches helps optimize your testing strategy:

While megger testing measures DC resistance at relatively low voltages (typically 500V-5000V), surge testing applies higher impulse voltages more closely replicating operational stresses. Meggers detect ground faults and gross insulation degradation but miss turn-to-turn shorts that surge testing readily identifies.

Key Difference: Meggers apply sustained DC voltage; surge testers use brief, high-voltage impulses revealing different defect types.

Hipot testing applies sustained high voltage to verify insulation can withstand operational voltages plus safety margins. The comparison between surge testers and hipot testers highlights their complementary roles—hipot tests verify absolute insulation strength while surge tests detect comparative weaknesses between phases.

Key Difference: Hipot testing stresses insulation to destruction threshold; surge testing evaluates at sub-destructive levels for ongoing monitoring.

Simple resistance measurements using standard multimeters detect open circuits and gross winding damage but provide no information about insulation integrity. Surge testing specifically targets insulation evaluation, making it essential for predictive maintenance programs.

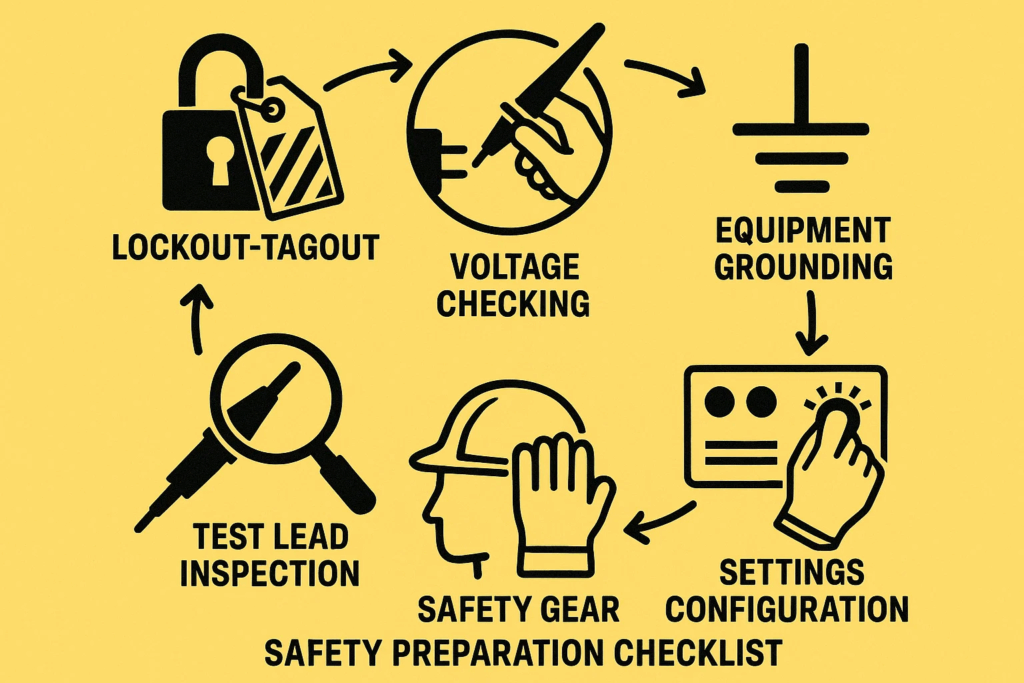

Proper testing technique ensures accurate results and operator safety:

Safety First:

Equipment Setup:

Initial Reference Test: Perform baseline testing on a known-good phase or section to establish reference waveforms. This comparison standard proves essential for identifying anomalies.

Systematic Phase Testing: Test each phase individually, comparing waveforms against the reference. Document test voltage, ambient temperature, and any environmental factors affecting results.

Progressive Voltage Testing: When warranted, gradually increase test voltage while monitoring for waveform changes indicating insulation stress or partial failure.

Documentation: Record all waveforms, test parameters, and observations. Modern testers automatically generate reports, but manual notation of unusual conditions provides valuable context for future analysis. Learning how to test armature using a surge tester applies similar principles to rotating equipment.

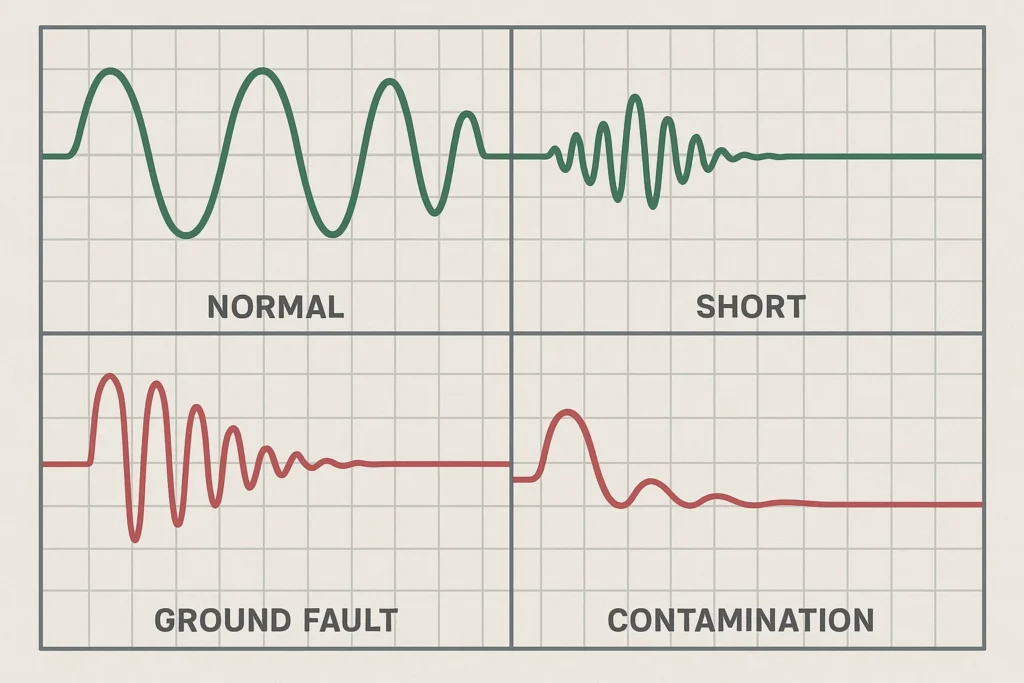

Accurate waveform analysis separates effective predictive maintenance from mere data collection:

Quality windings produce smooth, symmetrical oscillating waveforms with consistent frequency, amplitude, and damping characteristics. When overlaid, waveforms from identical phases should match almost perfectly, with deviations under 5% considered acceptable for most applications.

Turn-to-Turn Shorts: Waveform frequency increases while amplitude decreases compared to reference. The additional turn-to-turn capacitance alters the resonant frequency, creating distinctive patterns experienced technicians recognize immediately.

Phase-to-Phase Faults: Significant waveform distortion with irregular oscillations and premature damping indicates phase insulation breakdown. This serious condition requires immediate attention before progressing to complete failure.

Ground Faults: Asymmetric waveforms with abnormal damping patterns suggest compromised ground insulation. These defects create safety hazards and typically worsen rapidly once initiated. Understanding surge tester insulation failures helps identify critical issues early.

Contamination or Moisture: Excessive damping with reduced oscillation persistence often indicates moisture ingress or contamination. While less immediately critical, these conditions accelerate insulation degradation requiring remediation.

Single-point testing provides valuable diagnostic information, but trending results over time enables truly predictive maintenance. Gradual waveform changes signal developing problems before they reach critical thresholds, allowing optimized intervention timing.

Selecting appropriate testing equipment requires evaluating several critical factors:

Match tester capabilities to your largest generator specifications with adequate margin. Testing 480V generators requires different equipment than 13.8kV utility-scale machines. Consider future equipment additions when specifying tester ratings. Comprehensive guidance on choosing the right surge tester helps navigate available options.

Portable testers offer flexibility for field testing and service applications, while stationary laboratory systems provide enhanced capabilities for high-volume testing or research applications.

Modern surge testers range from basic comparison instruments to sophisticated systems with automated defect detection, trending databases, and comprehensive reporting. Balance capability requirements against budget constraints and operator expertise.

Quality testing equipment represents significant investment requiring manufacturer support for calibration, technical assistance, and spare parts availability. Established manufacturers provide superior long-term value through reliable performance and ongoing support.

Verify testing equipment meets relevant industry standards and safety certifications. Quality manufacturers provide documentation confirming compliance with IEEE, IEC, and safety standards.

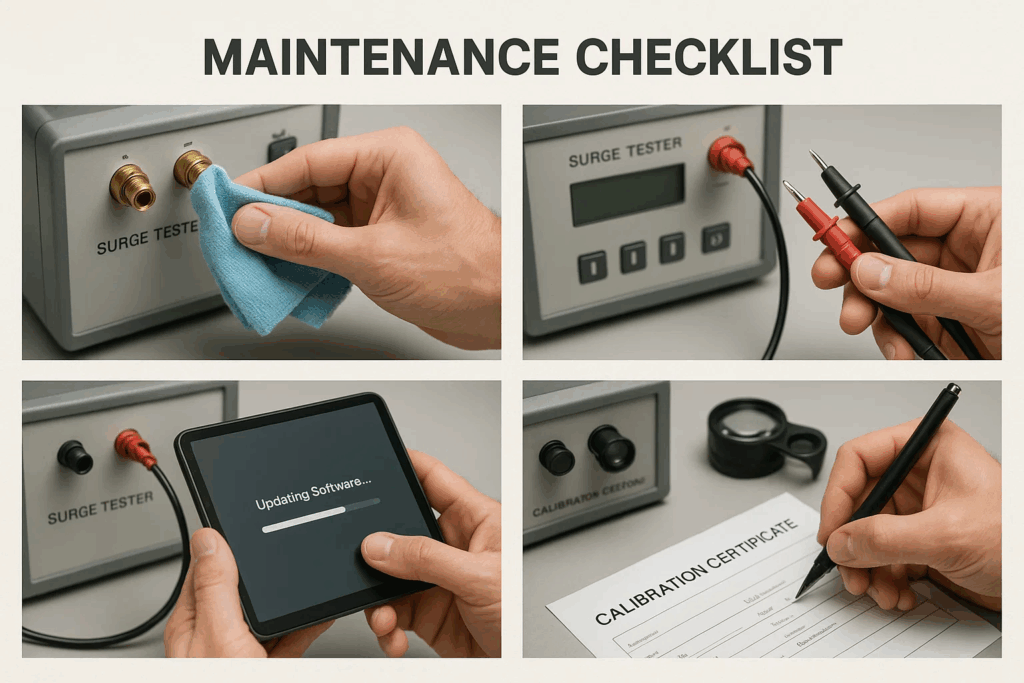

Maintaining surge tester accuracy and reliability requires systematic attention:

Annual calibration by qualified technicians or certified laboratories ensures measurement accuracy. Calibration verifies voltage output, timing precision, and waveform capture systems meet specifications. Detailed maintenance and calibration procedures preserve equipment performance.

Store surge testers in climate-controlled environments protecting against temperature extremes, humidity, and contaminants. Transport equipment in protective cases preventing mechanical shock and vibration damage.

Invest in comprehensive training ensuring operators understand testing principles, proper procedures, and safety requirements. Skilled technicians generate more valuable data while minimizing equipment damage and safety incidents.

Even experienced technicians encounter testing challenges requiring systematic troubleshooting:

Challenge: Repeated tests produce varying waveforms despite stable conditions.

Solution: Verify consistent connection quality, eliminate environmental electrical noise, ensure stable test voltage, and confirm equipment calibration. Ambient temperature variations also affect measurements—document testing conditions thoroughly.

Challenge: External electrical noise corrupts waveform captures.

Solution: Test in electrically quiet environments when possible, improve grounding systems, use shielded test leads, and enable noise filtering features available in advanced testers. Understanding common surge tester errors helps resolve interference issues.

Challenge: Managing high voltages safely in diverse field conditions.

Solution: Strictly follow lockout-tagout procedures, use properly rated personal protective equipment, maintain clear testing areas, and never override safety interlocks. Regular safety training refreshes maintain awareness.

Challenge: Results fall between clearly acceptable and obviously failed.

Solution: Establish trending baselines, consult manufacturer specifications, compare with historical data from similar equipment, and consider conservative approaches when safety-critical applications are involved.

A generator surge tester is an advanced diagnostic tool used to evaluate the integrity of electrical windings in generators, motors, and transformers by applying high-voltage impulses to insulation systems, which helps reveal defects missed by conventional testing methods

Unlike traditional tests that measure resistance or continuity at low voltages, surge testing uses controlled high-voltage impulses to simulate real-world electrical stress and detect subtle insulation defects, such as turn-to-turn shorts and phase mismatches, that standard tests might not identify

Surge testers identify turn-to-turn shorts, phase-to-phase faults, ground faults, and contamination issues (like moisture), by analyzing distortions, frequency shifts, and damping changes in the captured waveforms compared to reference patterns.

Effective surge testing involves proper equipment setup, performing reference and progressive voltage tests, systematic waveform comparison, documentation of findings, and ensuring technician safety with adherence to recommended practices and standards.

Generator surge testers represent essential diagnostic tools for any organization depending on reliable electrical equipment. These sophisticated instruments detect insulation weaknesses invisible to conventional testing methods, enabling predictive maintenance strategies that dramatically reduce unexpected failures and associated costs.

Implementing comprehensive surge testing programs delivers measurable benefits: extended equipment lifespans, reduced downtime, optimized maintenance spending, and enhanced operational safety. As electrical systems grow more complex and reliability expectations increase, surge testing’s role becomes increasingly critical. The comprehensive approach of surge testing enhancing motor reliability demonstrates proven value across industries.

Whether you’re establishing a new testing program or upgrading existing capabilities, investing in quality surge testing equipment and proper training yields exceptional returns through improved asset reliability and reduced operational disruptions.

Ready to enhance your electrical maintenance program? Explore our comprehensive range of professional surge testing solutions designed for industrial applications, or discover our advanced electrical testing equipment engineered to meet the most demanding diagnostic requirements. Our experienced team stands ready to help you select the optimal testing solution for your specific applications, ensuring long-term equipment reliability and operational excellence.