Hidden motor failures cost manufacturers thousands in unexpected downtime—yet 85% of winding defects remain undetected until catastrophic failure strikes. Waveform analysis in surge testing transforms invisible electrical signatures into diagnostic intelligence, revealing turn-to-turn faults, insulation weaknesses, and manufacturing defects before they escalate. This advanced technique empowers maintenance teams to predict failures, optimize quality control, and extend equipment lifespan through precision pattern recognition.

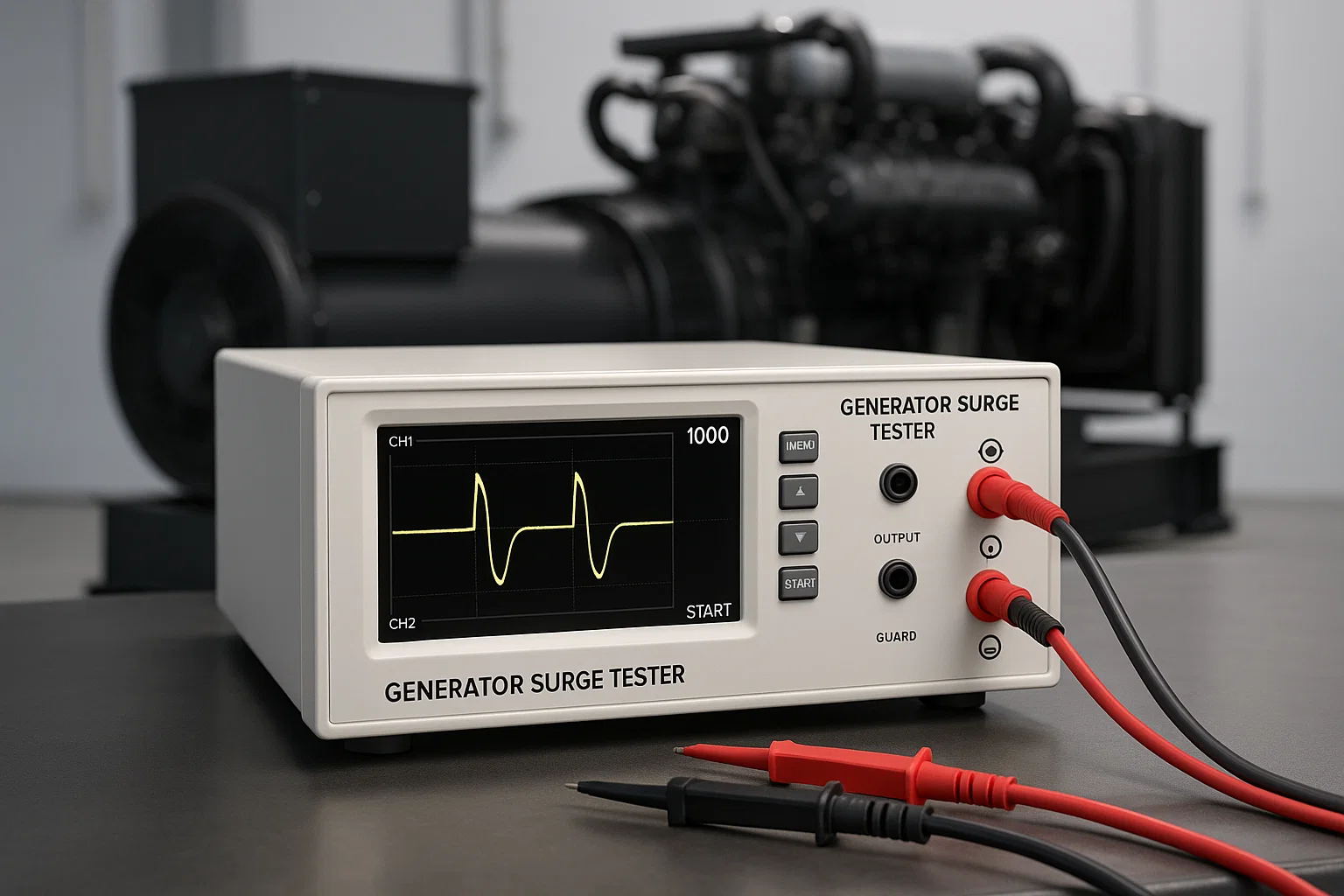

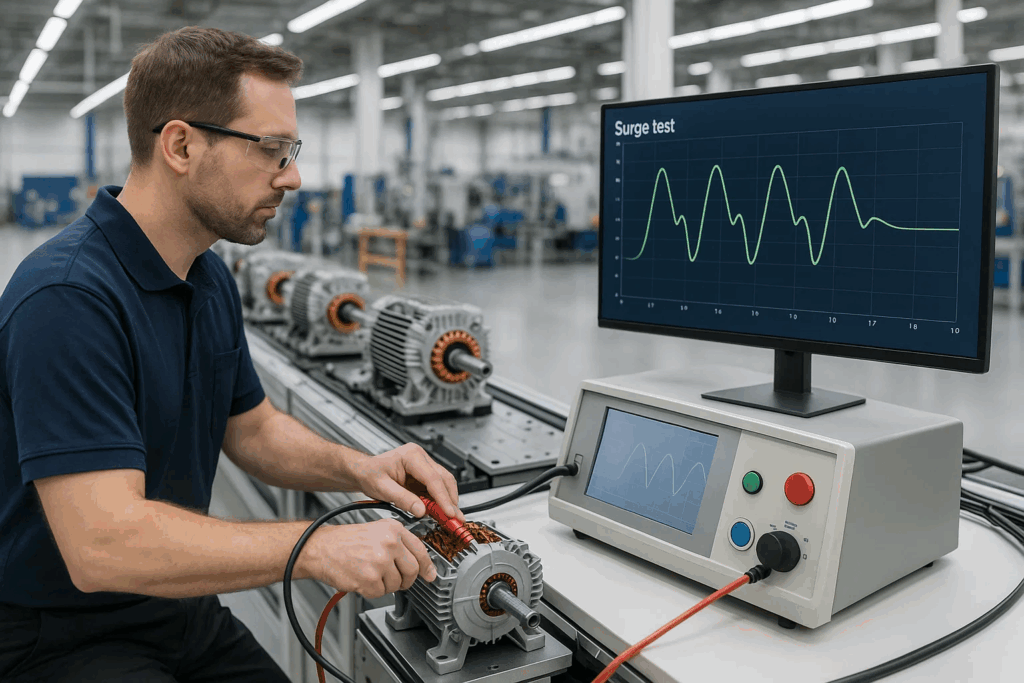

Waveform analysis represents the cornerstone of modern electrical diagnostics, transforming raw voltage patterns into actionable intelligence. When a surge tester applies a controlled high-voltage pulse to motor windings, the resulting electrical signature creates distinctive patterns that reveal the internal health of the component.

Every electrical component possesses unique impedance characteristics that influence how voltage propagates through its structure. During impulse testing, these characteristics manifest as:

The visual representation of these parameters creates a diagnostic fingerprint that experienced technicians can interpret with remarkable precision. This electrical signature analysis has revolutionized predictive maintenance strategies across industries.

Traditional pass-fail testing provides binary results, but waveform analysis delivers nuanced insights. A motor might pass basic resistance measurements yet harbor turn-to-turn faults that only reveal themselves under surge conditions. The voltage waveform captures these subtle anomalies that conventional testing methods miss.

Understanding how surge generators work enhances your ability to interpret the resulting patterns. The controlled energy discharge creates a momentary stress condition that mimics years of operational wear, forcing latent defects to surface during testing rather than during critical operations.

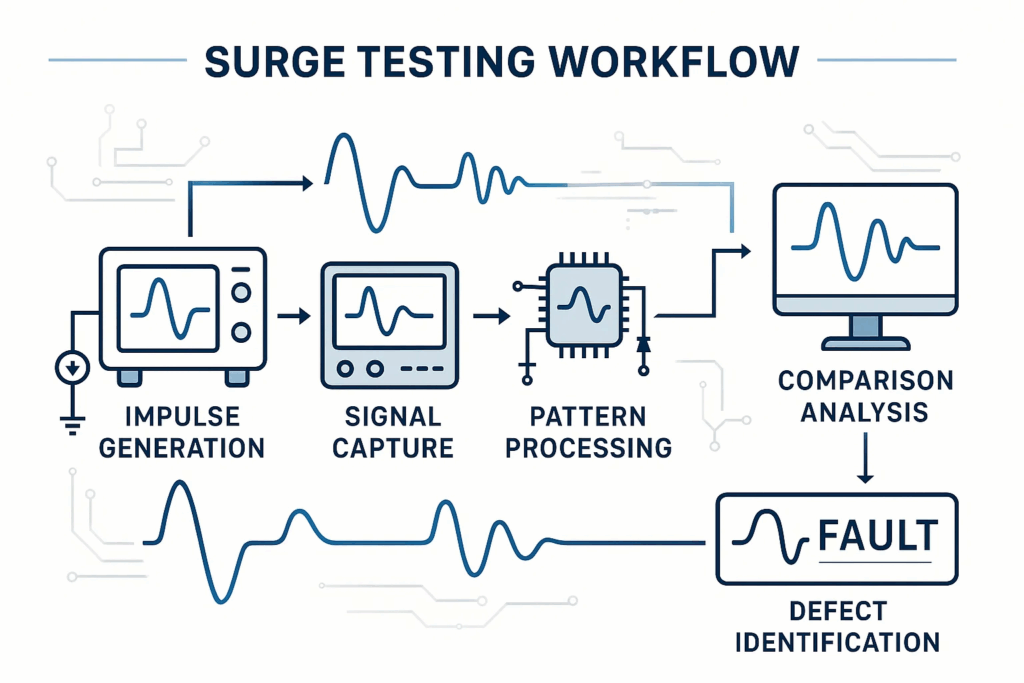

The waveform analysis process follows a systematic approach that combines physics, electronics, and pattern recognition to deliver comprehensive diagnostic results.

When technicians initiate a surge test, the equipment executes a precisely orchestrated sequence:

This multi-stage approach ensures that even microscopic insulation defects don’t escape detection. The precision of modern digital armature surge testers has elevated waveform analysis from art to science.

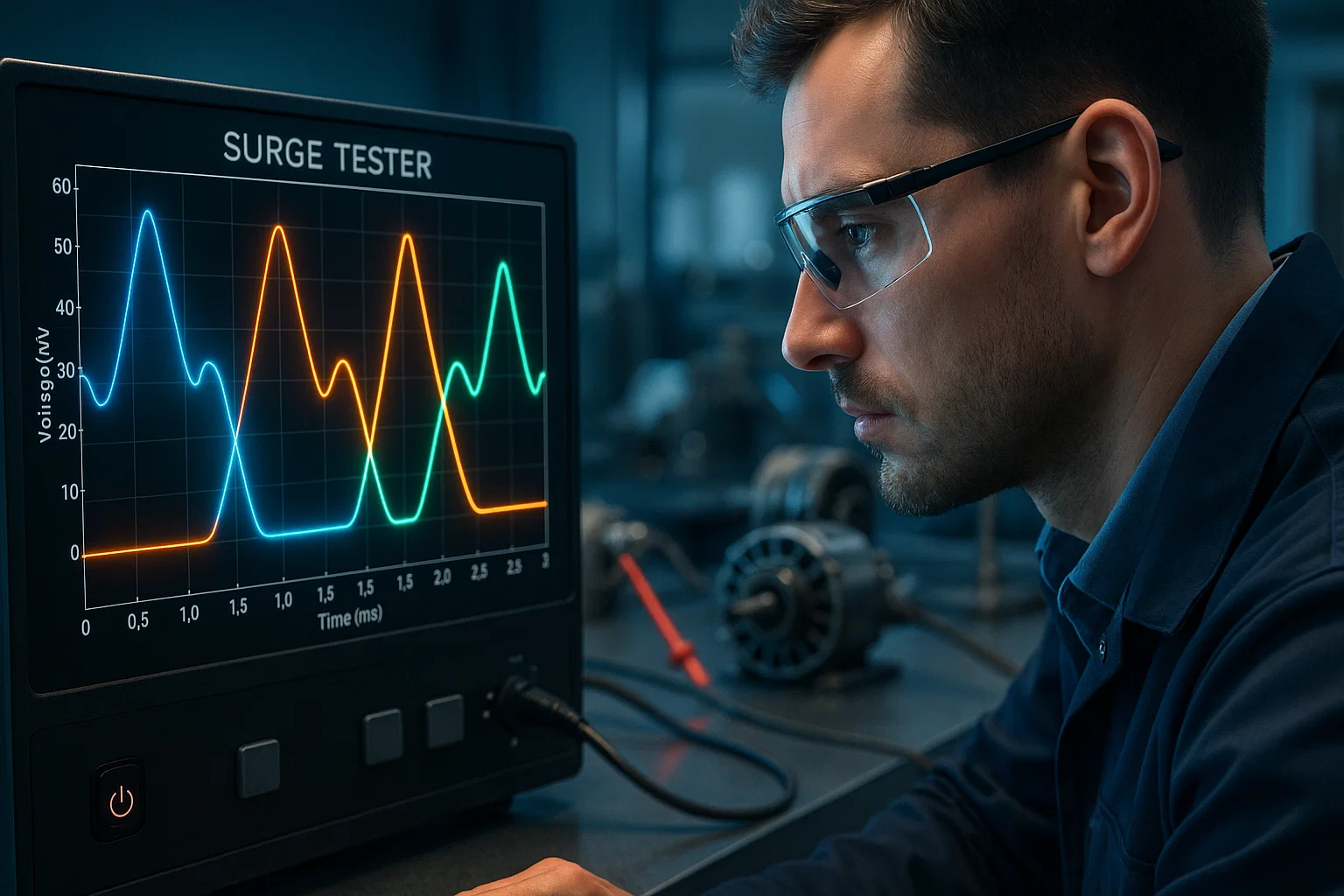

Raw electrical signals undergo sophisticated processing before presentation to the operator. Digital signal processing techniques filter noise, enhance relevant features, and overlay comparative data for intuitive interpretation. The display typically presents:

These visualization methods transform complex electrical phenomena into accessible diagnostic tools that don’t require advanced electrical engineering degrees to interpret.

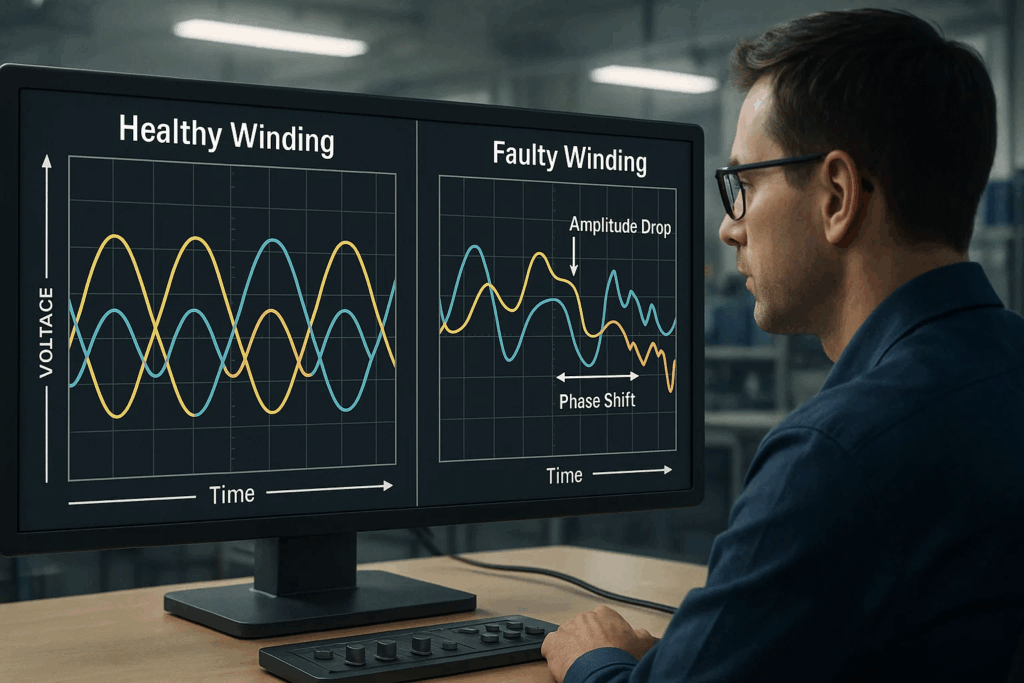

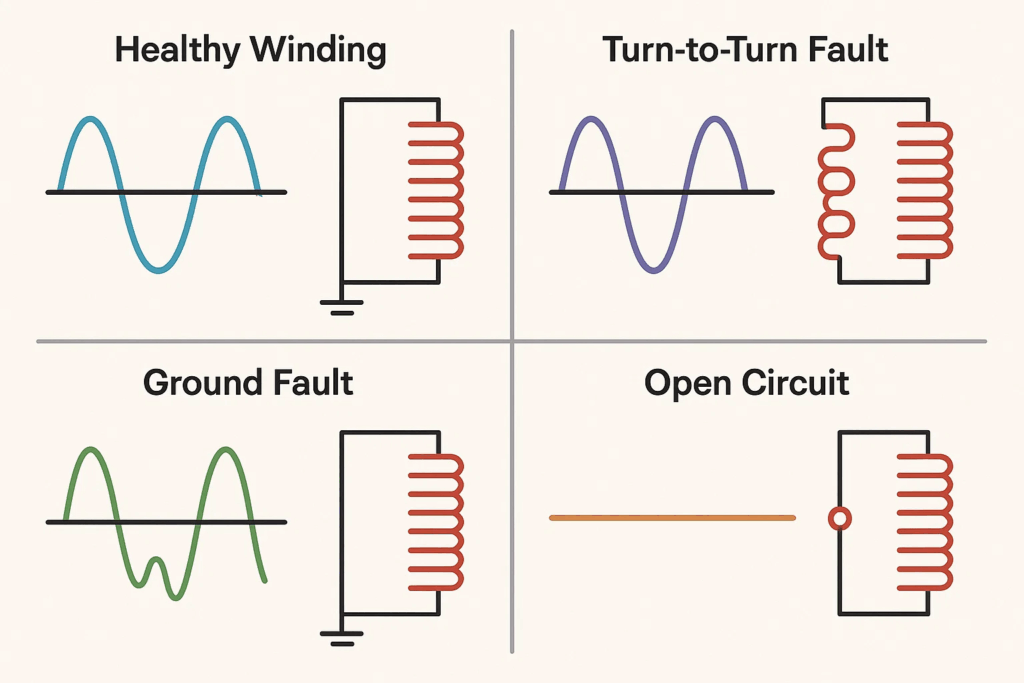

Mastering waveform interpretation requires familiarity with common patterns and their diagnostic implications. Each signature tells a specific story about winding condition and potential failure modes.

A properly functioning motor winding produces a characteristic damped oscillation pattern with:

When testing motor windings, these baseline characteristics serve as the reference standard against which all subsequent measurements are compared.

Short circuits between adjacent turns create distinctive waveform distortions. The reduced inductance in the affected coil causes:

These patterns emerge clearly during phase comparison analysis, where overlaying traces from multiple windings reveals even subtle discrepancies.

Insulation breakdown between windings and the motor frame manifests as:

Detecting surge tester insulation failures early prevents catastrophic motor damage and extends operational lifespan significantly.

Broken conductor strands or poor connections create unique signatures characterized by:

These unmistakable patterns immediately alert operators to critical winding defects requiring immediate attention.

The adoption of waveform-based diagnostics delivers measurable advantages across quality control, maintenance, and operational efficiency domains.

Pattern recognition identifies nascent failures long before conventional testing methods register anomalies. Research demonstrates that waveform analysis detects:

This predictive capability transforms maintenance from reactive to proactive, scheduling repairs during planned downtime rather than emergency shutdowns.

Manufacturing facilities implementing waveform analysis report dramatic improvements in product consistency. The technique enables:

The benefits of using surge testers with advanced waveform capabilities extend far beyond simple pass-fail determinations.

Financial benefits materialize through multiple channels:

Organizations report return on investment within 6-12 months of implementing comprehensive waveform analysis programs.

Industries subject to stringent quality standards leverage waveform documentation for:

Digital waveform records provide irrefutable evidence of thorough testing protocols and quality assurance rigor.

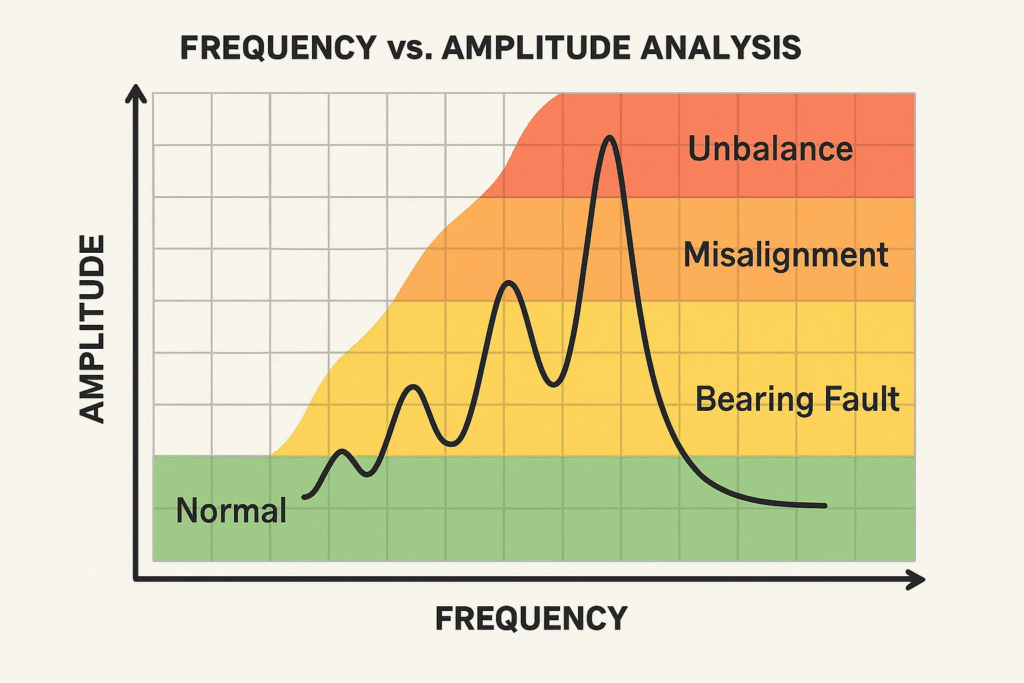

Beyond basic pattern recognition, experienced diagnosticians identify subtle variations indicating specific failure mechanisms and root causes.

Voltage peak deviations signal multiple potential issues:

10-20% Reduction:

20-40% Reduction:

Greater than 40% Reduction:

When troubleshooting common surge tester errors, distinguishing between equipment artifacts and genuine winding issues becomes critical for accurate diagnosis.

The oscillation frequency relates directly to winding inductance and capacitance. Changes indicate:

Frequency Increase:

Frequency Decrease:

Precise frequency measurement enables quantitative defect assessment, calculating the approximate number of affected turns based on percentage frequency deviation.

Overlay analysis of multiple winding waveforms reveals asymmetry issues invisible in individual traces:

This comparative approach dramatically improves detection sensitivity, identifying 5-10% deviations that might otherwise go unnoticed.

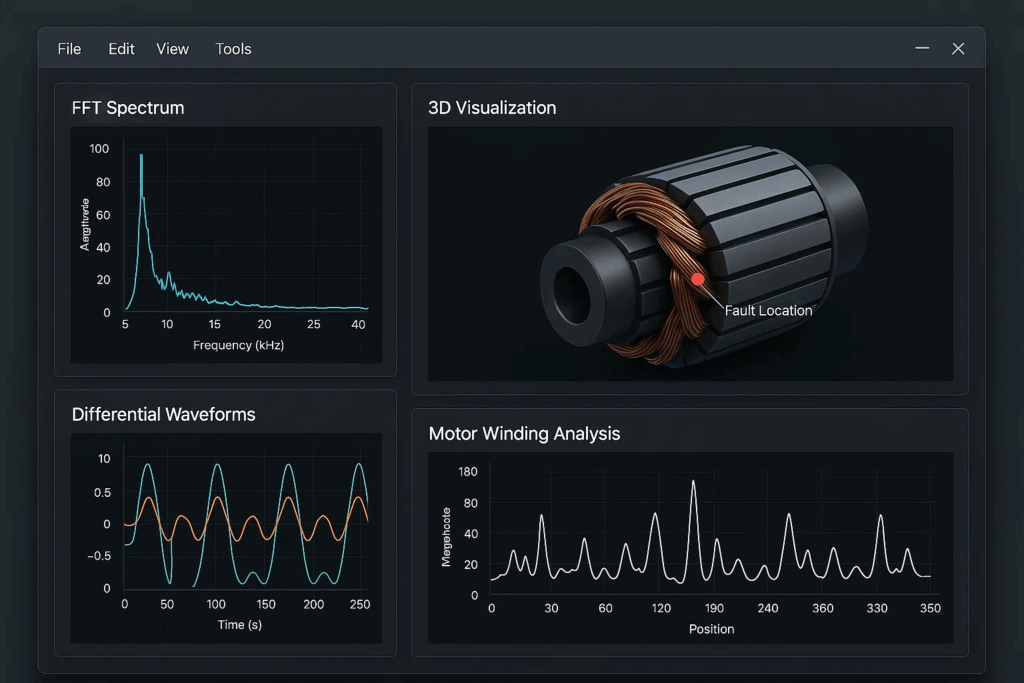

Sophisticated diagnostic applications employ enhanced analysis methods that extract additional intelligence from surge test data.

Frequency domain analysis decomposes complex waveforms into constituent frequency components, revealing:

FFT techniques prove particularly valuable when investigating intermittent failures or subtle degradation patterns.

Advanced systems calculate difference curves between test and reference waveforms, amplifying subtle anomalies. Benefits include:

These computational approaches enable detection limits approaching 2-3% variation from baseline standards.

Combining surge testing with reflectometry techniques pinpoints the physical location of defects within winding structures. The method:

This capability proves invaluable for large rotating machinery where selective coil replacement offers significant cost advantages over complete rewinding.

The applications of digital surge testers continue expanding as computational power enables increasingly sophisticated analysis algorithms.

Waveform analysis transcends traditional motor testing, finding applications across diverse industrial sectors and equipment types.

Production environments deploy inline surge testing with waveform analysis for:

Electric Motor Manufacturing:

Transformer Production:

Quality managers report defect detection rates improving from 70% to 98% following waveform analysis implementation.

Service organizations integrate waveform trending into condition monitoring strategies:

Companies implementing these programs report 40-60% reductions in unplanned downtime and 30% decreases in maintenance costs.

Portable surge testers with waveform capabilities enable on-site troubleshooting:

Understanding how to test armature using a surge tester becomes essential for field technicians supporting diverse equipment populations.

Engineering teams leverage waveform analysis during product development:

R&D applications often push equipment capabilities to extremes, requiring the most advanced waveform processing features available.

Reliable diagnostic results depend on proper testing procedures, equipment maintenance, and operator expertise.

Maximize data quality through systematic preparation:

Equipment Verification:

Test Specimen Conditioning:

Baseline Establishment:

These foundational steps ensure that subsequent analysis compares valid data against reliable references.

Configure test voltage and timing parameters appropriately:

Voltage Selection:

The distinction between surge tester vs hipot tester becomes important when determining appropriate test voltages for specific applications.

Timing Considerations:

Improper parameter selection leads to inconclusive results or false failure indications.

Apply systematic analysis methodology:

Experienced technicians develop pattern recognition expertise through exposure to diverse fault signatures and equipment types.

Preserve measurement accuracy through regular maintenance:

Understanding how to maintain and calibrate your digital surge tester ensures consistent, reliable diagnostic results over equipment lifespan.

Selecting appropriate waveform analysis capabilities requires matching equipment features to application requirements and technical sophistication.

Priority capabilities for effective diagnostics include:

Display and Visualization:

Data Acquisition:

Analysis Functions:

These features transform raw oscilloscope traces into actionable diagnostic intelligence.

Different surge testing approaches offer varying waveform analysis capabilities:

Traditional Impulse Testers:

Digital Surge Analyzers:

Integrated Test Systems:

Understanding the difference between megger and surge test for windings helps contextualize where waveform analysis provides unique value beyond complementary testing methods.

Match equipment capabilities to operational requirements:

Manufacturing Environment:

Service Workshop:

Field Service:

Knowing how surge testing enhances motor reliability and efficiency justifies investment in advanced waveform analysis capabilities appropriate to your operational context.

Equipment investment should align with expected returns:

Entry-Level Systems ($5,000-$15,000):

Mid-Range Systems ($15,000-$40,000):

Premium Systems ($40,000-$100,000+):

Calculate payback period considering prevented failures, quality improvements, and labor efficiency gains. Most organizations achieve positive ROI within 18-24 months.

Waveform analysis in surge testing is a diagnostic technique that examines the voltage patterns created when high-voltage pulses are applied to motor windings. The resulting oscilloscope-style traces reveal turn-to-turn faults, insulation weaknesses, and manufacturing defects by analyzing amplitude, frequency, and shape characteristics. This method detects defects at 90% accuracy compared to 60-70% with traditional pass-fail testing.

While basic surge testing provides simple pass/fail results, waveform analysis offers detailed visual patterns showing exactly where and how severe defects are. Standard testing might miss subtle turn-to-turn shorts or early insulation degradation, but waveform analysis captures these anomalies through pattern comparison, frequency shifts, and amplitude variations—enabling predictive maintenance rather than reactive repairs.

Surge testing is the process of applying high-voltage impulses to motor windings to stress-test insulation, while waveform analysis is the method of interpreting the resulting voltage patterns. Think of surge testing as the diagnostic procedure and waveform analysis as the interpretation tool—together they provide comprehensive electrical diagnostics beyond simple pass/fail results.

Yes, waveform analysis enables predictive maintenance by identifying early-stage degradation patterns. The technique detects insulation weakening at approximately 70% of breakdown voltage and can identify single-turn shorts before they cascade into catastrophic failures. Organizations using waveform trending report 40-60% reductions in unplanned downtime.

Effective waveform analysis requires a digital surge tester with high-resolution display, minimum 1 MHz sampling rate, multi-trace overlay capability, and data storage functions. Advanced systems include FFT spectrum analysis, automated comparison algorithms, and trending software. Entry-level equipment starts around $5,000, while comprehensive systems range from $15,000-$40,000.

Waveform analysis achieves 90% detection accuracy for turn-to-turn faults and identifies defects as small as single shorted turns—significantly outperforming resistance testing (60-70% accuracy) or basic hipot testing. When combined with other techniques like insulation resistance testing and vibration analysis, waveform analysis provides the most comprehensive motor diagnostics available.

Manufacturing sectors including automotive, aerospace, HVAC, renewable energy (wind turbines), and industrial motor production gain substantial benefits. Any industry relying on critical rotating equipment—from petrochemical plants to data centers—uses waveform analysis for quality control, predictive maintenance, and regulatory compliance. The technology is essential wherever motor failures result in costly downtime or safety hazards.

Waveform analysis in surge testing represents the pinnacle of electrical diagnostic technology, transforming invisible voltage patterns into precise, actionable intelligence about motor and winding condition. This sophisticated technique detects nascent failures at the earliest stages—long before conventional testing methods register anomalies—enabling predictive maintenance strategies that dramatically reduce downtime and extend equipment lifespan.

From manufacturing quality control to field service troubleshooting, waveform analysis delivers measurable benefits across diverse applications. The technology’s ability to visualize turn-to-turn faults, insulation degradation, and manufacturing defects provides diagnostic certainty that protects critical assets and optimizes operational efficiency.

As motor systems grow increasingly complex and operational demands intensify, adopting advanced waveform analysis capabilities transitions from competitive advantage to operational necessity. Organizations investing in proper equipment, training, and testing protocols position themselves to minimize unplanned failures, reduce maintenance costs, and maximize asset reliability.

Vivid Metrawatt Global offers industry-leading surge testing solutions with advanced waveform analysis capabilities designed for your specific applications. Our expert team provides comprehensive training, ongoing support, and technical guidance ensuring you extract maximum value from your diagnostic investment.

Explore our complete range of:

Contact our specialists today to discuss how waveform analysis can enhance your quality assurance, predictive maintenance, and reliability programs. Don’t wait for failures to dictate your maintenance schedule—take control with predictive intelligence.