HVAC motor failures cost businesses thousands in emergency repairs and system downtime every year. A single undetected winding defect can cascade into complete motor failure, leaving facilities without climate control during critical periods. The solution? Implementing surge testing as part of your preventive maintenance strategy. This comprehensive guide reveals which surge testers deliver the most accurate diagnostics for HVAC applications, helping you protect your investment and ensure uninterrupted operation.

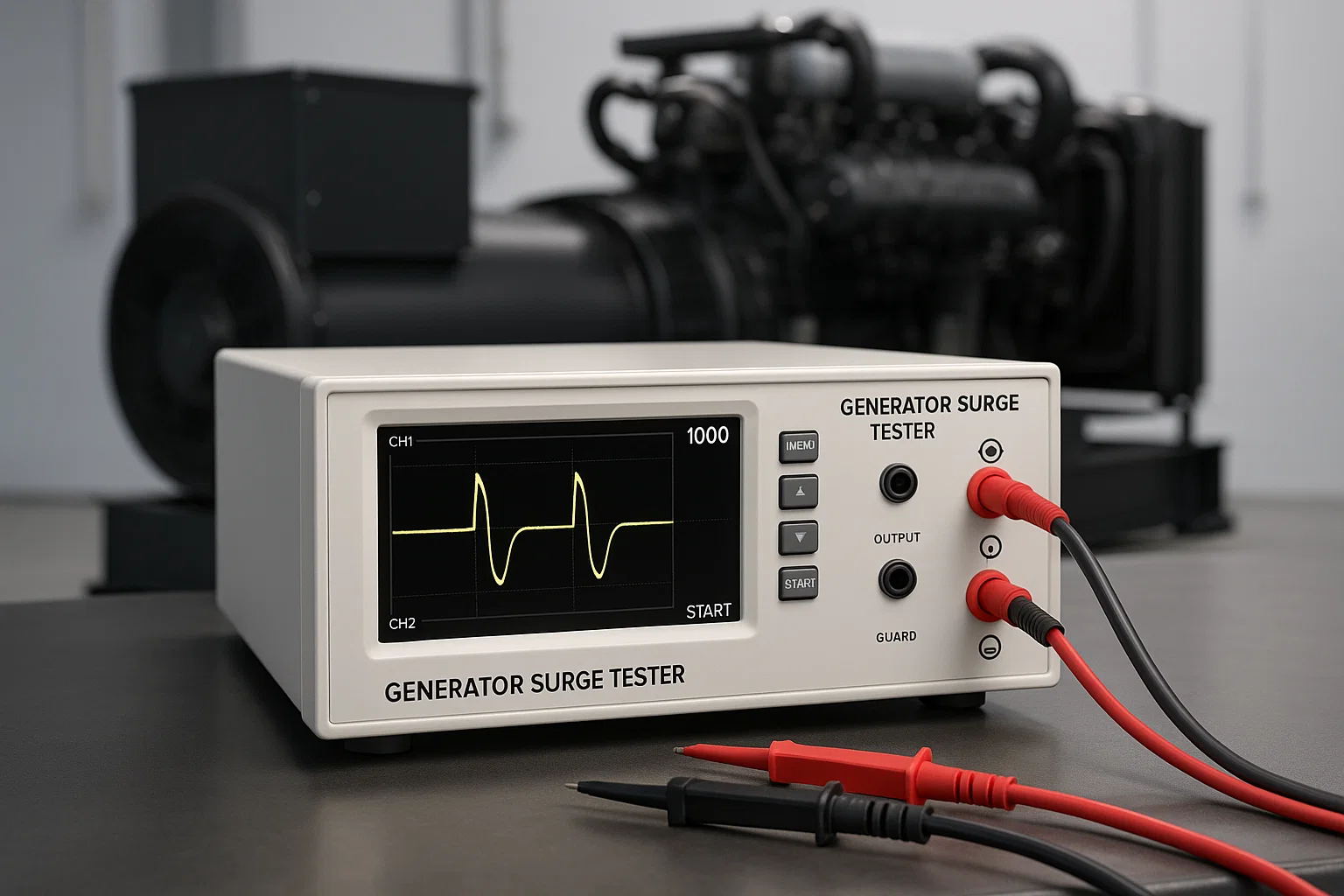

Surge testing represents the gold standard for detecting insulation weaknesses in motor windings before they cause catastrophic failures. Unlike basic resistance measurements, surge testing applies a controlled high-voltage pulse to windings, revealing defects invisible to conventional testing methods.

How Surge Testing Works:

For HVAC applications, surge testing becomes particularly critical because these motors operate continuously under varying load conditions, temperature fluctuations, and environmental stresses that accelerate insulation degradation.

HVAC motors face unique operational challenges that make standard motor testing insufficient:

Temperature Cycling HVAC motors experience dramatic temperature swings during startup, operation, and shutdown cycles. These thermal stresses cause insulation materials to expand and contract repeatedly, creating micro-fractures that conventional resistance tests cannot detect.

Moisture Exposure Condensation, humidity, and occasional water intrusion compromise insulation integrity. Moisture penetration creates conductive pathways that may not register on basic continuity tests but will reveal themselves during surge testing.

Contamination Issues Dust, debris, and chemical exposure in HVAC environments deposit on windings, creating potential failure points. Understanding motor winding failure signs helps technicians identify when surge testing becomes necessary.

The benefits of using surge testers become apparent when considering the cost of unexpected HVAC failures versus planned maintenance interventions.

Selecting the right surge tester for HVAC applications requires evaluating specific capabilities that align with your testing needs.

Voltage Range and Adjustability

Waveform Analysis Capabilities

Sensitivity and Detection Accuracy

Display Quality Modern surge testers should feature high-resolution color displays showing multiple waveforms simultaneously, with intuitive touchscreen controls that simplify operation in challenging environments.

Portability Considerations

Automated Testing Protocols Look for testers offering pre-programmed test sequences specifically designed for HVAC motor types, reducing operator error and ensuring consistent results.

Data Logging and Documentation

Multi-Function Capability Premium surge testers often integrate additional testing modes:

Choosing the right surge tester involves balancing these features against your budget and specific application requirements.

Ideal Specifications:

Recommended Features: For residential applications, surge testers should prioritize portability and ease of use. Single-phase motor testing capability covers most residential needs, with occasional three-phase testing for larger systems.

Price Range: $2,500 – $5,000

These units excel at testing furnace blowers, air handler motors, condenser fan motors, and heat pump compressors commonly found in residential installations.

Ideal Specifications:

Recommended Features: Commercial applications demand more sophisticated testing due to larger motors and more complex systems. The ability to perform comprehensive motor winding tests becomes essential for preventive maintenance programs.

Key Applications:

Price Range: $5,000 – $10,000

Ideal Specifications:

Critical Requirements: Hospitals, data centers, pharmaceutical facilities, and manufacturing plants require maximum reliability. Applications of digital surge testers in these environments extend beyond simple pass/fail testing to comprehensive condition monitoring.

Advanced Features:

Price Range: $10,000 – $25,000+

Precision and Documentation Digital surge testers provide quantifiable measurements with numerical deviation percentages, eliminating subjective interpretation. This precision proves invaluable when:

Advanced Analysis Capabilities Digital platforms incorporate sophisticated algorithms that identify specific failure modes:

Data Management Modern digital testers store comprehensive test histories, enabling:

While digital technology dominates, analog surge testers retain advantages in specific scenarios:

Simplicity and Reliability

Budget Constraints For small HVAC service companies performing basic diagnostics, analog testers offer adequate functionality at significantly lower investment ($800-$2,000 vs $2,500-$25,000).

Field Ruggedness Traditional analog construction often withstands harsh field conditions better than sensitive digital electronics, though modern digital units increasingly incorporate military-grade ruggedization.

Safety Protocols Before conducting surge testing, ensure:

Motor Preparation

Phase 1: Initial Assessment Begin with the lowest test voltage (typically 100-200V) to establish baseline readings without risking damage to marginally weak insulation.

Phase 2: Incremental Testing Gradually increase voltage in 100-500V steps, monitoring waveforms at each level:

Phase 3: Maximum Voltage Testing Apply the specified test voltage (typically 2x rated voltage + 1000V) to reveal marginal defects:

Phase 4: Interpretation Analyze results using manufacturer-specific criteria:

Troubleshooting common surge tester errors ensures accurate results and prevents misdiagnosis.

Single-Phase Motors Test between start winding, run winding, and common terminal. Compare impedance values against manufacturer specifications.

Three-Phase Motors Test all six possible winding combinations:

Variable Speed Motors VFD-duty motors require special consideration due to enhanced insulation systems. Test at standard voltages but interpret results using VFD motor-specific criteria.

Detection Method Surge testing excels at identifying turn-to-turn shorts that create subtle changes in winding inductance. These failures produce characteristic waveform distortions showing reduced peak voltage and altered time constants.

Typical Causes in HVAC Motors:

Failure Progression Turn-to-turn shorts typically begin with just a few shorted turns, gradually expanding until they create phase-to-phase or phase-to-ground faults. Early detection through surge testing prevents complete motor failure.

Characteristics This failure mode shows significant deviations when comparing affected phases. The surge tester reveals asymmetry that standard resistance tests might miss until the fault becomes severe.

HVAC-Specific Causes:

Surge tester insulation failure detection proves particularly valuable for identifying ground wall problems before they cause catastrophic failures.

Detection Indicators:

Environmental Factors: HVAC environments accelerate ground wall deterioration through:

Detection Method Surge testing reveals contamination paths that create partial discharge sites. These appear as irregular waveform patterns and reduced breakdown voltages.

Prevention Through Testing Regular surge testing identifies contamination before it creates permanent damage, allowing for:

Emergency Repair Avoidance Emergency HVAC motor replacement costs 3-5 times more than planned replacements:

Extended Motor Life Surge testing enhances motor reliability and efficiency by enabling targeted interventions:

Example Scenario – Commercial Building:

Investment:

Annual Savings:

Payback Period: 3.9 months

Five-Year ROI: 1,429%

Tenant Satisfaction Reliable climate control directly impacts tenant retention in commercial properties. Preventing unexpected HVAC failures maintains comfort and satisfaction.

Energy Efficiency Motors with degrading windings operate less efficiently, consuming more energy. Early detection and replacement improve overall system efficiency.

Compliance and Documentation Comprehensive testing records support:

Daily Care:

Monthly Procedures:

Annual Service: Maintaining and calibrating your digital surge tester ensures continued accuracy and reliability:

Frequency Requirements:

Calibration Documentation: Maintain detailed records including:

High-voltage test leads represent the most frequently replaced surge tester components:

Inspection Criteria:

Replacement Guidelines: Replace leads immediately if showing:

The standard formula is 2x rated voltage + 1000V, with a maximum not exceeding the motor’s specified test voltage. For a 460V motor, this would be (2 x 460) + 1000 = 1920V. Always consult the motor manufacturer’s specifications for exact testing voltages.

When performed correctly at appropriate voltages, surge testing does not damage healthy motors. The test voltage stresses insulation within design limits. However, motors with severely degraded insulation may experience breakdown during testing, which prevents future catastrophic failure during operation.

Recommended frequencies vary by application:

Critical facilities: Quarterly

Commercial systems: Semi-annually

Residential systems: Annually or during major service

New installations: Before commissioning

After environmental events: As needed

Surge testing applies high-voltage pulses to detect turn-to-turn shorts and winding asymmetries, while megger testing applies DC voltage to measure insulation resistance to ground. Both tests provide complementary information, and combining them offers comprehensive motor assessment.

Always disconnect motors from VFDs before surge testing. The high-voltage test pulses can damage VFD electronics. Test at the motor terminals, not at the VFD output.

Yes, proper training ensures accurate results and safety. Training should cover:

High-voltage safety procedures

Proper connection techniques

Result interpretation

Equipment operation

Documentation requirements

Comprehensive records should include:

Motor identification and nameplate data

Test date and technician

Test voltages applied

Waveform comparisons or deviation percentages

Ambient conditions

Test equipment used

Recommendations and follow-up actions

Choosing the best surge tester for HVAC motor testing requires careful consideration of your specific needs, budget, and application requirements. Whether you’re servicing residential systems or maintaining critical commercial facilities, investing in appropriate testing equipment protects your motors, reduces downtime, and delivers substantial return on investment.

Key Selection Factors:

Next Steps:

Ready to implement surge testing in your HVAC maintenance program? Browse our selection of professional-grade digital surge testers designed specifically for HVAC applications, or contact our technical team for personalized equipment recommendations based on your unique requirements.

Investing in quality surge testing equipment today prevents costly motor failures tomorrow while establishing your reputation as a thorough, professional HVAC service provider committed to customer satisfaction and system reliability.

About Vivid Metrawatt Global

Vivid Metrawatt Global specializes in precision electrical testing equipment for industrial and commercial applications. With over 15 years of experience providing innovative diagnostic solutions, we help maintenance professionals worldwide ensure equipment reliability through advanced testing technologies.