Seized bolts and rusted fasteners bring industrial operations to a grinding halt, costing businesses thousands in downtime and equipment damage. Traditional methods—hammering, torching, and chemical penetrants—often fail, risking stripped threads and workplace hazards. Induction heating for bolt removal offers a revolutionary solution, delivering precise, controlled heat that expands metal components without compromising structural integrity. This advanced technique transforms what once took hours into minutes, ensuring your operations run smoothly while protecting both workers and equipment.

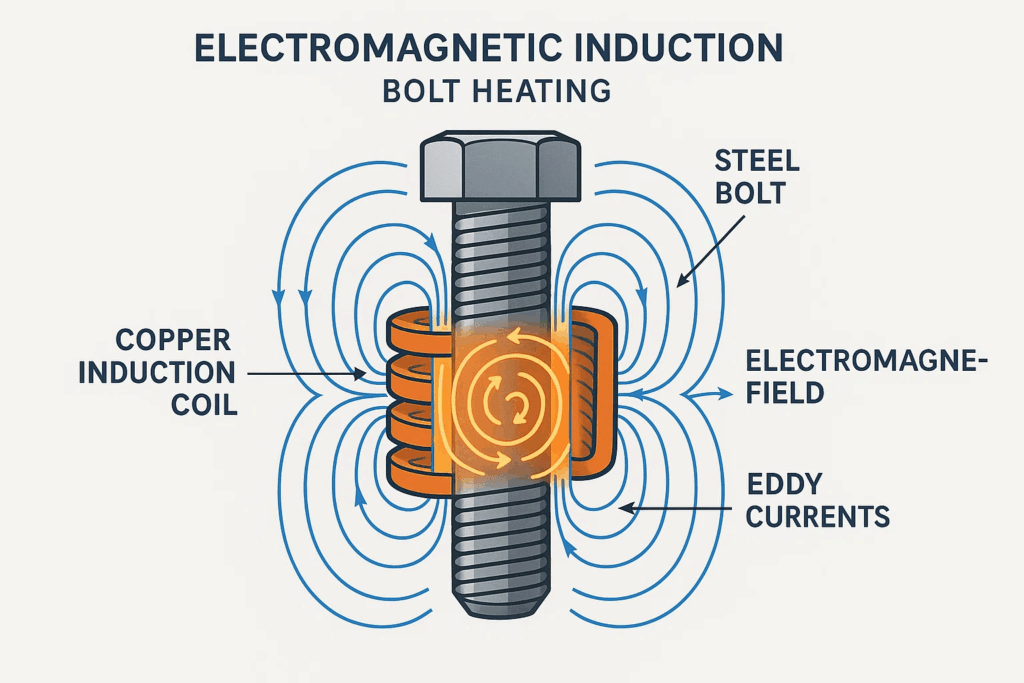

Induction heating represents the pinnacle of modern thermal engineering. Unlike conventional heating methods that rely on direct flame or radiant heat, this sophisticated technology uses electromagnetic fields to generate heat directly within metallic components.

The process operates through electromagnetic induction principles—a phenomenon discovered by Michael Faraday in 1831. When alternating current flows through a copper coil, it creates a rapidly changing magnetic field. This field induces eddy currents within any conductive material placed inside the coil, generating heat through electrical resistance.

Key advantages include:

Understanding proper induction heating coil design ensures maximum efficiency and optimal heat transfer for your specific bolt removal applications.

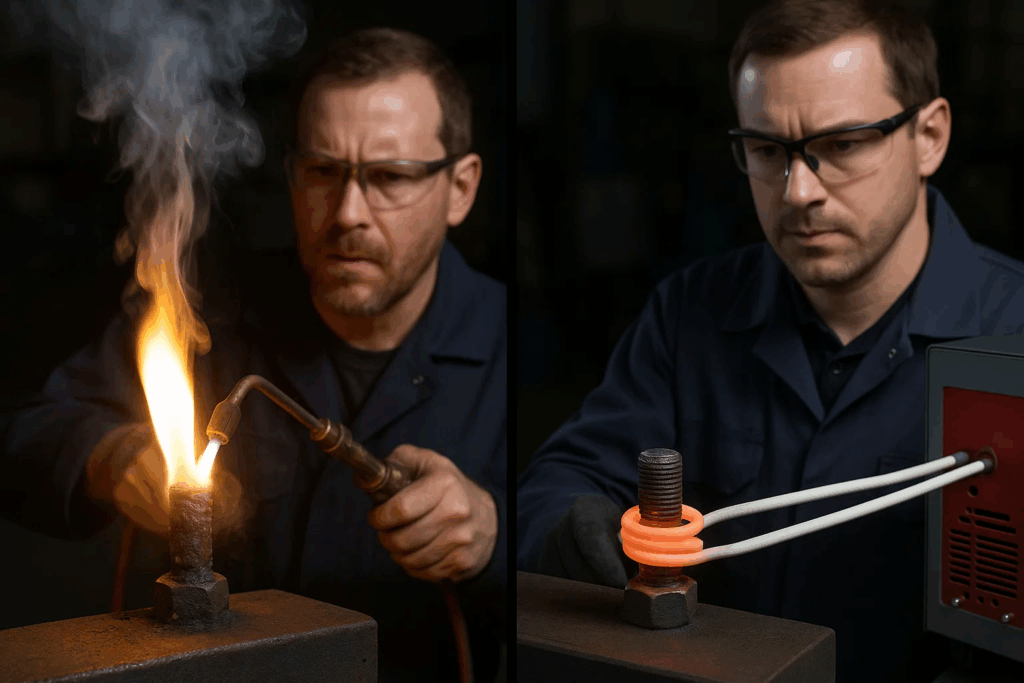

Traditional bolt removal techniques present significant limitations. Open flames create fire hazards and uneven heating. Impact tools risk thread damage. Chemical solutions require extended dwell times and environmental disposal concerns.

When you apply induction heating to industrial applications, the targeted heating creates controlled thermal expansion. The bolt or surrounding material expands rapidly, breaking the corrosion bond without affecting adjacent components. This differential expansion proves particularly effective with:

Many professionals wonder about induction heating versus resistance heating methods. Induction heating offers superior control, localized heat application, and faster cycle times compared to traditional resistance-based approaches.

Speed: Induction heating achieves working temperatures in 30-90 seconds compared to 5-15 minutes with traditional methods.

Precision: Temperature control within ±5°C prevents metallurgical changes while ensuring effective loosening.

Safety: Flameless operation eliminates ignition risks in hazardous environments where flammable materials or gases are present.

Consistency: Repeatable results across multiple applications ensure predictable outcomes and reduced operator training time.

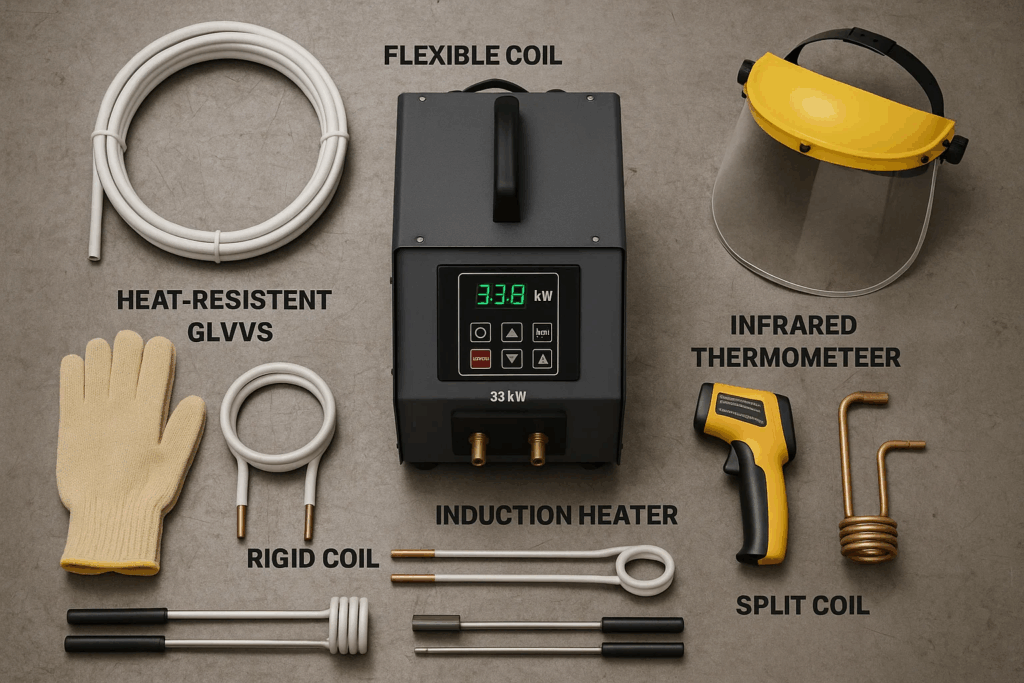

The equipment selection process demands careful consideration of your specific operational requirements. Power output, frequency range, and coil design all influence effectiveness. Learn more about how to select the right induction heater for steel heat work to optimize your bolt removal operations.

Power Requirements:

For bolt removal applications, 22kW, 33kW, and 44kW induction heaters deliver optimal performance across most industrial scenarios. Smaller fasteners (M8-M16) work efficiently with 22kW units, while larger industrial bolts (M20-M48) benefit from 33kW or 44kW systems.

Coil Configuration:

Safety remains paramount in induction heating operations. Comprehensive protection ensures both operator welfare and equipment longevity.

Required Safety Gear:

Modern safety features in induction heaters include automatic shutoff systems, overtemperature protection, and electromagnetic field limiting technology that maintains operator exposure within safe parameters.

Surface Preparation: Remove loose debris, scale, and coating materials from the target area. Clean surfaces ensure optimal electromagnetic coupling and prevent contamination during heating.

Component Evaluation: Assess bolt size, material composition, and surrounding components. Understanding materials suitable for induction hardening helps predict heating behavior and optimal temperature ranges.

Equipment Setup: Position the induction heater within comfortable working distance. Ensure adequate ventilation and clear evacuation paths. Verify power supply stability and grounding integrity.

Strategic Coil Placement: Wrap the induction coil around the bolt head or nut, maintaining consistent spacing of 2-5mm. For seized bolts in blind holes, position the coil around the surrounding material to create expansion. The principles used in heating bushings safely apply equally to bolt removal applications.

Power Application: Activate the system using progressive power settings. Begin at 30-40% power for 15-20 seconds, then increase to 60-70% as needed. Monitor color changes—the appearance of dull red indicates temperatures around 500-600°C, optimal for most removal operations.

Temperature Monitoring: Use infrared thermometers or integrated temperature sensors to track thermal progression. Target temperatures vary by application:

Mechanical Removal: Once optimal temperature is reached, immediately apply removal torque using appropriate tools. The thermal expansion window lasts 30-60 seconds before cooling begins.

Controlled Cooling: Allow components to cool naturally in still air. Avoid rapid cooling with water or compressed air, which can induce thermal shock and cracking in stressed materials.

Post-Removal Inspection: Examine threads for damage, check surrounding components for distortion, and verify successful removal without collateral impact.

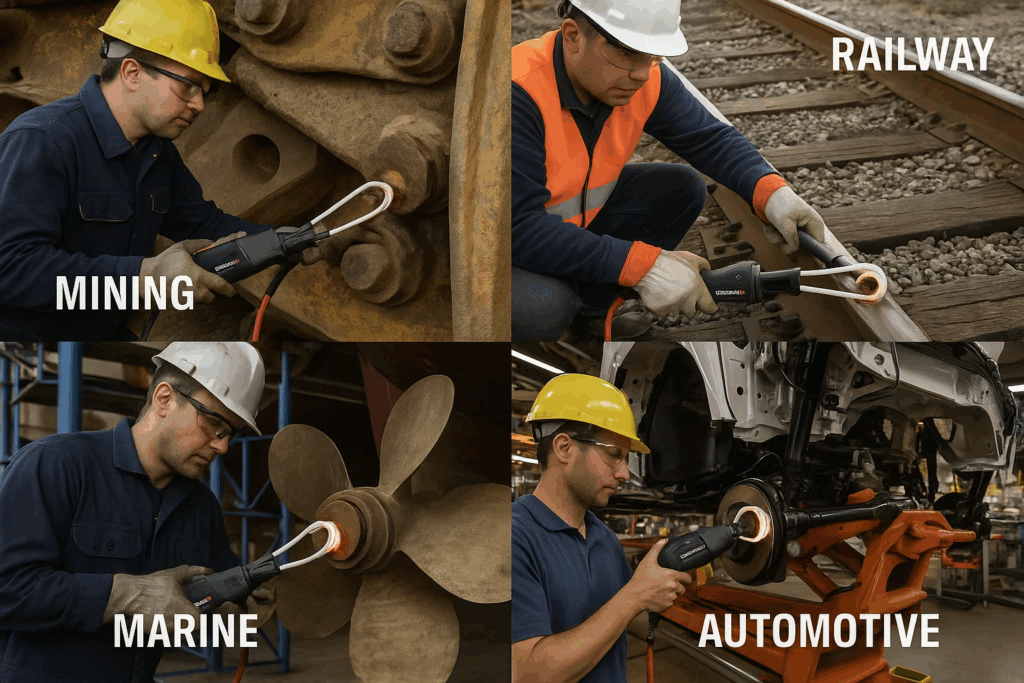

Mining operations leverage induction heating for bolt removal in crusher assemblies, conveyor systems, and excavator components. One Australian mining company reported 75% reduction in maintenance downtime after implementing induction heating solutions for railways and heavy industrial equipment.

Rail systems employ this technology for track maintenance, replacing traditional cutting methods that require costly rail replacement. The process removes seized anchor bolts without damaging rail integrity, enabling in-place repairs.

Shipyards face constant battles with saltwater corrosion. Induction heating successfully removes propeller bolts, rudder fasteners, and hull fittings without the fire hazards associated with torch work in confined spaces.

Assembly plants use induction heating for automotive industry applications during warranty work and component replacement. The precision prevents damage to adjacent sensors, wiring harnesses, and plastic components that traditional methods would compromise. Similar techniques apply to induction heating shrink fitting for bearing installation and removal.

Industrial facilities maintaining turbines, generators, and heavy machinery benefit from induction heating for large rotors and assemblies. The technology handles seized bolts in components weighing several tons without requiring complete disassembly.

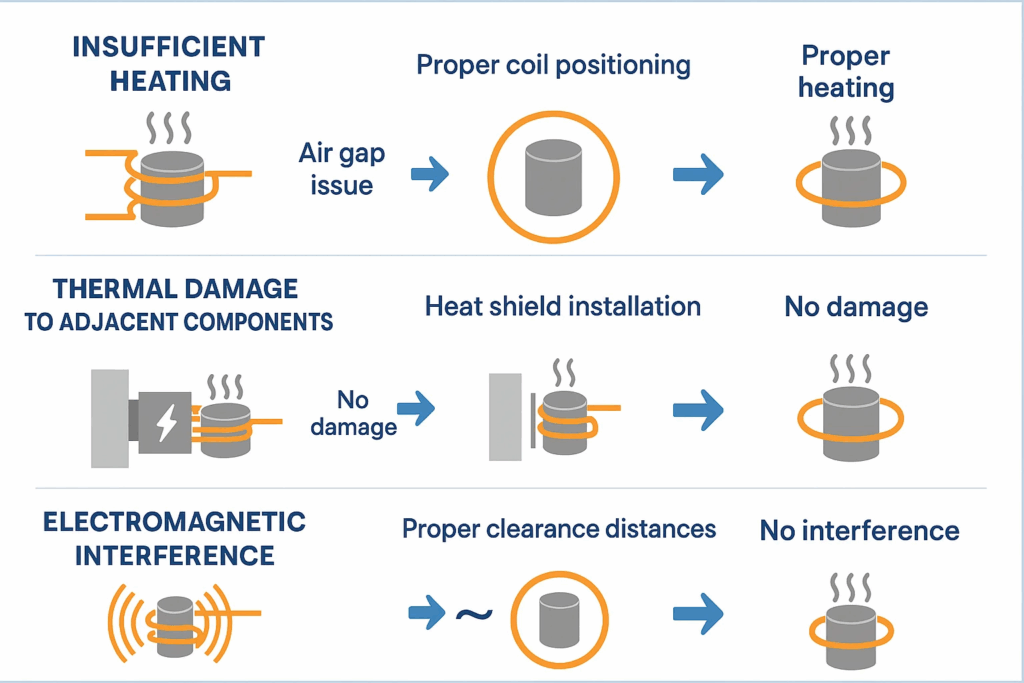

Symptom: Bolt remains seized despite extended heating cycles.

Solutions:

Symptom: Adjacent materials show discoloration or distortion.

Solutions:

Symptom: Nearby electronic systems exhibit erratic behavior during operation.

Solutions:

Initial Equipment Costs:

Explore our complete range of professional induction heating equipment to find solutions matching your operational requirements and budget constraints.

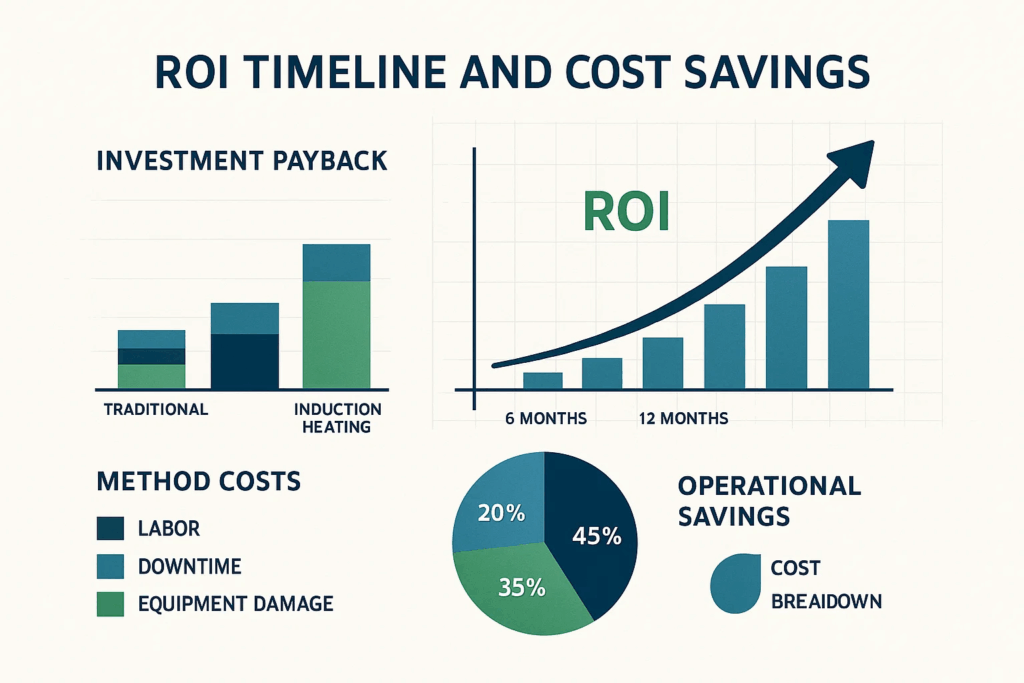

Labor Cost Reduction: Technicians complete bolt removal tasks 60-80% faster compared to conventional methods. A single seized bolt that previously required 2-3 hours now takes 15-30 minutes.

Equipment Preservation: Eliminating mechanical force prevents thread damage, component replacement costs drop 40-50% as fasteners and threaded holes remain serviceable. The same precision used in induction forging operations ensures controlled heating without metallurgical damage.

Downtime Mitigation: Rapid resolution of seized fastener issues returns equipment to production faster. Manufacturing facilities report average savings of $5,000-$15,000 per avoided production stoppage.

Safety Improvements: Reduced workplace injuries from slipped wrenches, struck-by incidents, and repetitive strain translate to lower insurance premiums and workers’ compensation claims.

Facilities performing regular maintenance on heavy equipment typically achieve ROI within 6-18 months. High-volume operations with frequent seized fastener challenges recover investment costs within 3-6 months through labor and downtime savings alone.

The required power depends on bolt size and material composition. For general industrial applications, a 22kW induction heater handles bolts up to M16 effectively. Medium-sized fasteners (M16-M30) perform optimally with 33kW systems, while large industrial bolts (M30-M48) require 44kW units. Consider your most frequent bolt sizes when selecting equipment to ensure adequate heating capacity without excessive power consumption.

Typical heating times range from 30-90 seconds depending on bolt size, material, and corrosion severity. Small fasteners (M8-M12) reach working temperature in 30-45 seconds, while larger bolts (M30-M48) require 60-90 seconds. This represents an 80% time reduction compared to traditional torch heating methods that often require 5-15 minutes to achieve similar results.

When properly controlled, induction heating preserves thread integrity better than mechanical methods. The key lies in temperature management—maintaining heat below 700°C for standard steel fasteners prevents metallurgical changes. Unlike impact tools that can strip or deform threads, thermal expansion creates clean separation without mechanical stress. Always monitor temperatures and allow gradual cooling to minimize thermal shock.

Modern induction heaters incorporate electromagnetic shielding and frequency control to minimize interference. However, maintain a minimum 3-meter clearance from sensitive electronics, programmable logic controllers, and computer systems. When working in control rooms or near instrumentation, schedule heating operations during equipment shutdown windows or install additional electromagnetic shielding around vulnerable components.

Ferromagnetic materials—steel, iron, and certain alloys—respond most efficiently to induction heating due to their magnetic properties. Stainless steel fasteners heat effectively but require 20-30% more power than carbon steel. Aluminum and brass bolts heat more slowly and need specialized coil designs. Non-magnetic materials rely solely on electrical resistance for heating, requiring higher power levels and longer cycle times.

Yes, but aluminum requires different parameters than steel. Use 40-50% higher power settings and longer heating times (90-120 seconds). Target temperatures of 250-300°C work effectively for aluminum—higher temperatures risk material degradation. Specialized coil designs with reduced air gaps improve efficiency when heating non-ferromagnetic materials like aluminum and brass.

Install ceramic wool or refractory heat shields around temperature-sensitive components within 100mm of the heating zone. Apply thermal paste to heat sinks for electronic sensors. Position the induction coil to concentrate heat on the specific target area—proper coil placement reduces stray heating by 60-70%. For extreme situations, temporarily remove vulnerable components before heating operations.

Heating strategy depends on the specific application. For external bolts, direct heating of the bolt head creates expansion that breaks the corrosion bond. For bolts threaded into housings, heating the surrounding material expands the threaded hole, allowing easier extraction. Blind holes and recessed applications typically benefit from housing heating, while exposed fasteners respond better to direct bolt heating.

Professional induction heaters require minimal maintenance compared to traditional heating equipment. Inspect coil connections monthly for signs of overheating or degradation. Check cooling system fluid levels weekly during heavy use. Annual calibration ensures temperature accuracy and power output consistency. Replace worn coils immediately—damaged coils reduce efficiency by 30-40% and create safety hazards.

Absolutely. Induction heating excels at releasing thread-locking compounds. Most thread-lockers break down at temperatures between 200-260°C, well within the safe operating range for steel fasteners. Heat the bolt or housing for 45-60 seconds, allowing thermal penetration to soften the compound throughout the thread engagement. The combination of chemical breakdown and thermal expansion provides easy removal without chemical solvents.

Seek equipment certified to international safety standards including CE marking, UL listing, and CSA certification. Electromagnetic compatibility (EMC) certification ensures the unit won’t interfere with other equipment. Verify the manufacturer includes built-in safety features: overtemperature protection, automatic shutoff, ground fault detection, and electromagnetic field limiting. Professional-grade units should meet OSHA requirements for industrial heating equipment.

Induction heating for bolt removal represents more than technological advancement—it embodies a fundamental shift in maintenance philosophy. This sophisticated approach combines safety, efficiency, and precision, delivering consistent results that traditional methods cannot match.

Organizations embracing this technology position themselves at the forefront of industrial excellence. The combination of reduced downtime, enhanced safety protocols, and superior outcomes creates competitive advantages that extend beyond immediate operational benefits.

Ready to transform your maintenance operations? Explore our comprehensive range of professional induction heating systems designed specifically for demanding industrial applications. Our expert team provides tailored solutions matching your unique operational requirements, ensuring optimal performance from day one.