Selecting the wrong motor standard can cost your facility thousands in retrofit expenses, operational inefficiencies, and premature equipment failure. When industrial engineers and procurement specialists face motor selection decisions, they often encounter two dominant standards: NEMA and IEC. Without understanding these fundamental differences, you risk purchasing incompatible equipment, experiencing unexpected maintenance challenges, and compromising your operational efficiency. This comprehensive guide reveals the critical distinctions between NEMA and IEC motor standards, empowering you to make informed decisions that align with your application requirements and regional specification

Motor standards provide the framework for consistency, safety, and performance across global manufacturing and industrial applications. These standards define specifications for design, construction, performance characteristics, and testing protocols.

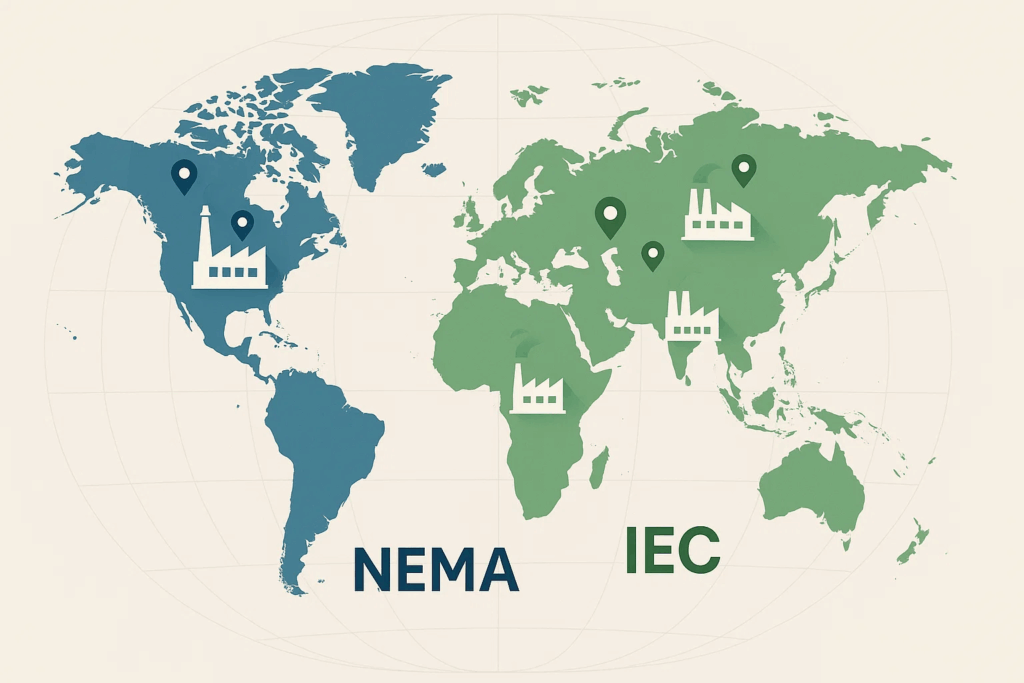

NEMA (National Electrical Manufacturers Association) dominates North American markets, while IEC (International Electrotechnical Commission) serves as the global standard adopted by most countries worldwide. Understanding these standards becomes essential when sourcing equipment, planning international projects, or ensuring compliance with regional regulations.

The standardization ensures that motors meet specific performance criteria, maintain safety protocols, and deliver predictable operational characteristics. Motor testing requirements follow these standards to validate motor integrity and performance capabilities.

NEMA standards originated in the United States and primarily govern motor specifications throughout North America. These standards emphasize robust construction, conservative design margins, and straightforward application parameters.

Key NEMA Characteristics:

NEMA motors excel in applications requiring durability, overload capacity, and straightforward replacement procedures. Their standardized dimensions ensure interchangeability across manufacturers, simplifying maintenance and procurement processes.

Quality assurance through comprehensive motor testing remains critical for NEMA-compliant equipment, ensuring motors meet specified performance standards before deployment.

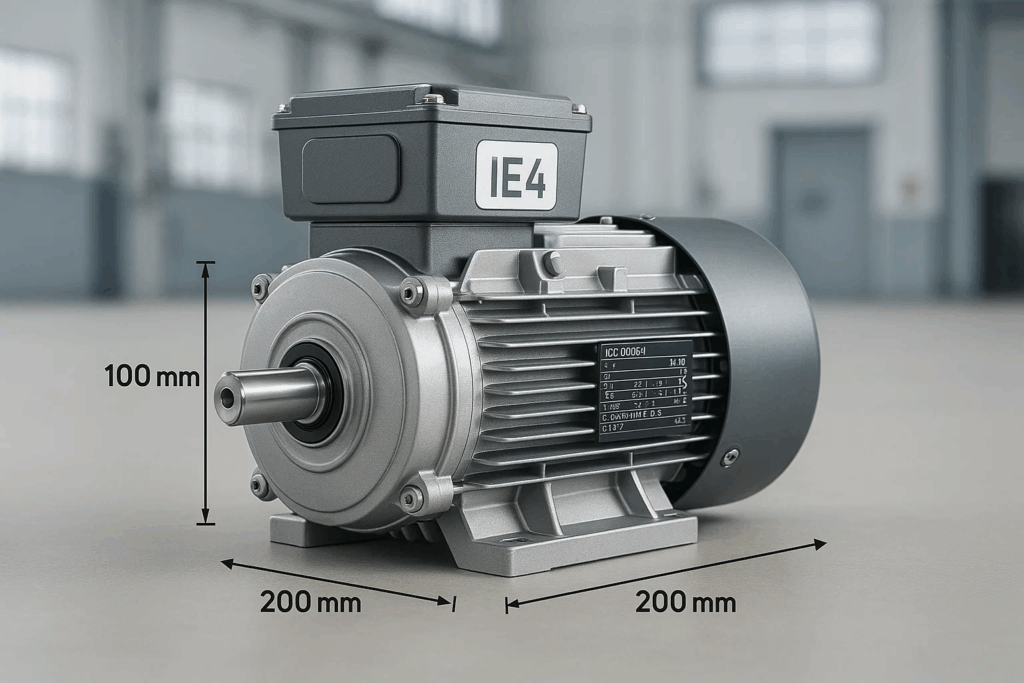

IEC standards represent the internationally recognized framework adopted by European, Asian, and most global markets. These standards prioritize efficiency, compact design, and metric-based specifications.

Key IEC Characteristics:

IEC motors provide excellent energy efficiency and space optimization, making them ideal for applications where footprint and power consumption matter. Their global acceptance facilitates international projects and multinational operations.

Advanced testing equipment ensures IEC motors meet stringent international quality and performance benchmarks throughout manufacturing and commissioning phases.

| Parameter | NEMA Standards | IEC Standards |

|---|---|---|

| Primary Region | North America | Global (except North America) |

| Measurement System | Imperial (inches, feet) | Metric (millimeters, meters) |

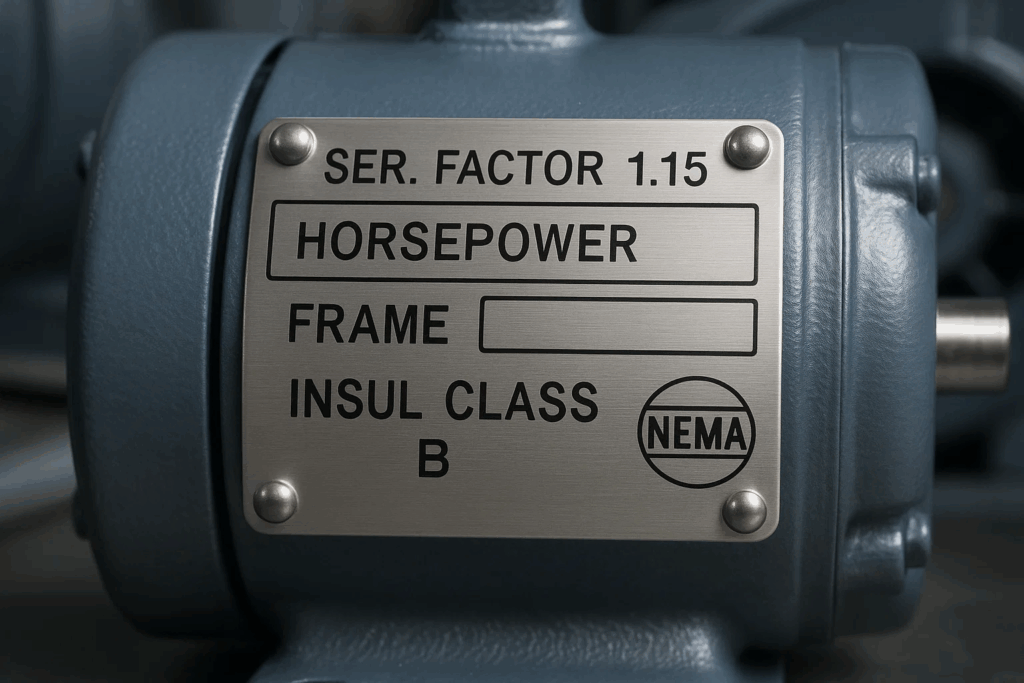

| Service Factor | Typically 1.15 (15% overload capacity) | 1.0 (no overload margin) |

| Frame Size | Larger with more robust construction | Compact, space-efficient design |

| Efficiency Rating | Nominal efficiency with service factor buffer | IE efficiency classes (IE1-IE4) |

| Power Rating | Horsepower (HP) | Kilowatts (kW) |

| Operating Temperature | Class B (130°C) standard | Class F (155°C) typical |

| Starting Torque | Generally higher | Optimized for specific applications |

| Mounting Dimensions | Standardized imperial measurements | Standardized metric measurements |

| Overload Protection | Integral thermal protection common | External protection typical |

| Testing Standards | NEMA MG-1 specifications | IEC 60034 series standards |

| Cost | Generally 10-30% higher | More cost-effective |

| Replacement Availability | Limited to North American market | Globally available |

| Typical Applications | Heavy-duty industrial, HVAC, pumps | Precision equipment, robotics, international projects |

Performance characteristics differ significantly between NEMA and IEC motors, impacting application suitability and operational costs.

NEMA Performance Attributes:

NEMA motors deliver robust performance with built-in safety margins. The service factor allows temporary overloading without damage, providing operational flexibility during peak demands. This conservative approach results in slightly lower efficiency ratings but enhanced durability.

IEC Efficiency Excellence:

IEC motors prioritize energy efficiency through the IE classification system:

Organizations focused on energy consumption and sustainability increasingly prefer IEC motors. Modern testing methodologies validate these efficiency claims through rigorous performance verification.

Torque Characteristics:

NEMA motors typically provide higher starting torque, beneficial for applications with heavy inertial loads. IEC motors optimize torque curves for specific operating conditions, delivering superior efficiency at design points.

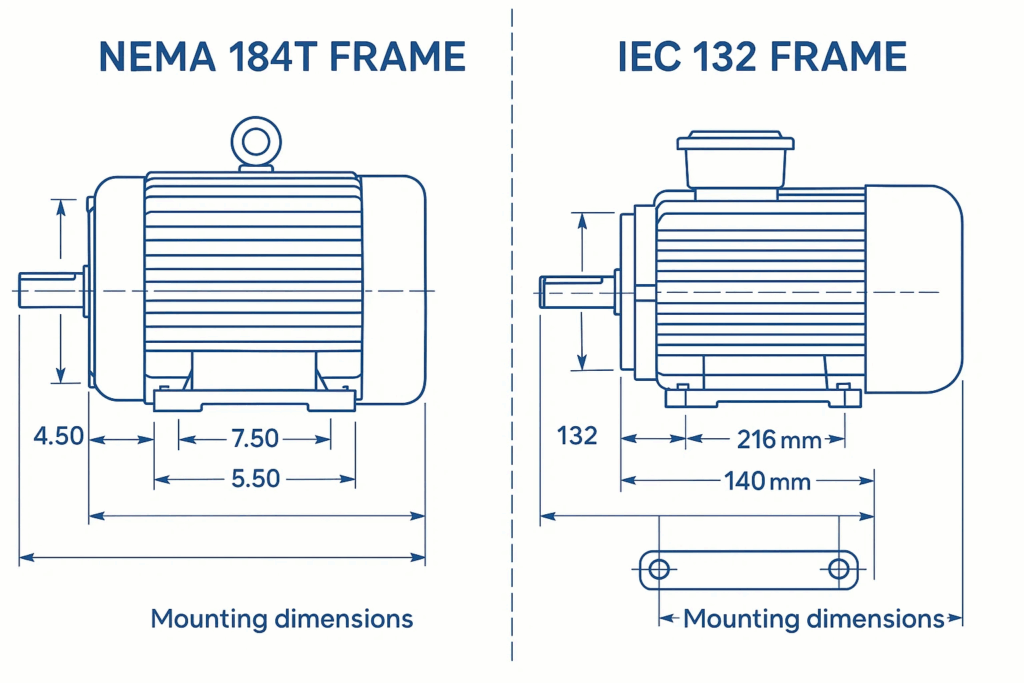

Physical dimensions and mounting configurations present practical challenges when replacing or specifying motors across standards.

NEMA Frame Dimensions:

NEMA uses a standardized frame designation system where numbers indicate specific dimensions:

IEC Frame Specifications:

IEC frame sizes reference shaft height in millimeters directly:

Mounting Compatibility Challenges:

Direct replacement between NEMA and IEC motors rarely works without modifications:

Planning equipment upgrades requires careful dimensional verification. Professional testing equipment ensures replacement motors meet performance specifications regardless of standard.

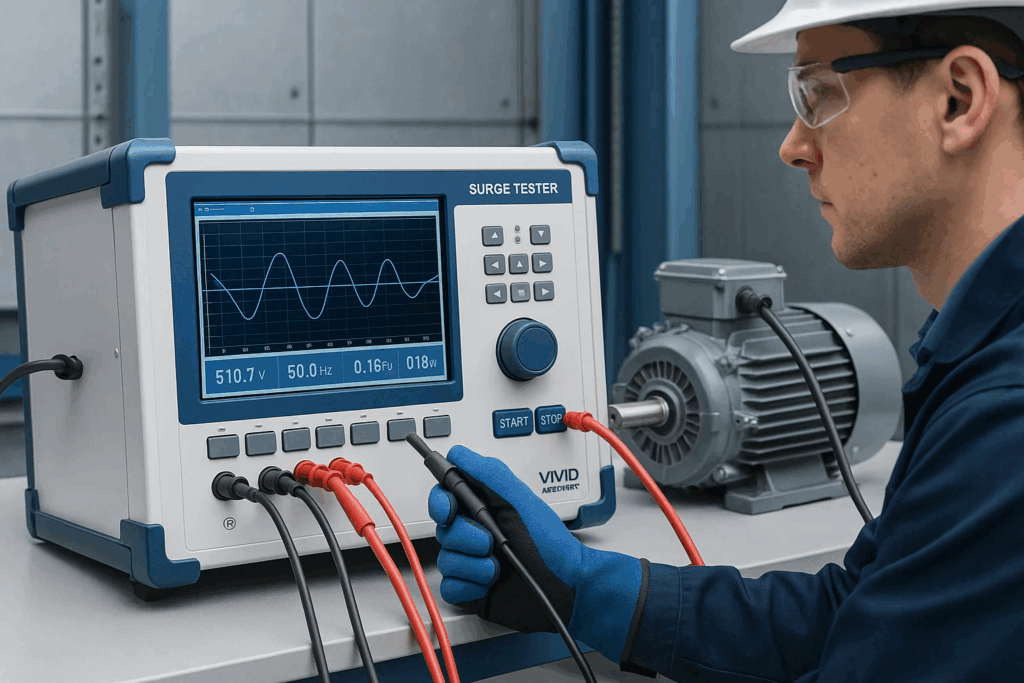

Both standards mandate rigorous testing protocols, though specific requirements differ.

NEMA Testing Protocols:

NEMA MG-1 specifies comprehensive testing including:

Digital surge testing plays a crucial role in identifying insulation weaknesses and turn-to-turn faults during NEMA motor qualification.

IEC Testing Standards:

IEC 60034 series defines testing requirements:

Quality Assurance Through Testing:

Regardless of standard, comprehensive surge testing remains essential for detecting manufacturing defects, insulation degradation, and winding faults before motors enter service.

Advanced facilities employ specialized testing equipment to validate motor performance across various operating conditions, ensuring reliability and longevity.

Geographic location significantly influences motor standard selection.

North American Market:

United States and Canadian facilities predominantly specify NEMA motors for:

Global Markets:

European, Asian, and South American operations favor IEC motors across:

Multinational Operations:

Companies operating across regions face standardization challenges. Many adopt IEC motors globally while maintaining NEMA specifications for North American facilities, creating dual inventory and maintenance complexity.

Financial implications extend beyond initial purchase price.

Initial Investment:

Long-Term Operating Costs:

IEC motors often deliver lower lifetime costs through:

Total Cost of Ownership:

Consider these factors:

Preventive maintenance through regular testing extends motor life and optimizes total ownership costs regardless of standard.

Selecting between NEMA and IEC motors requires evaluating multiple factors.

Decision Framework:

Professional Assessment:

Engage qualified engineers to evaluate:

Motor standards continue evolving toward enhanced efficiency and sustainability.

Emerging Developments:

Testing Evolution:

Advanced diagnostic tools enable more sophisticated analysis, predicting failures before they occur and optimizing motor performance throughout operational life.

Replacement requires careful evaluation of mounting dimensions, electrical characteristics, and performance requirements. Direct substitution rarely works without modifications.

IEC motors typically offer higher efficiency through IE classification requirements, though NEMA motors with service factors provide operational flexibility.

Both standards produce reliable motors when properly specified and maintained. NEMA’s conservative design provides overload margin, while IEC optimizes for design conditions.

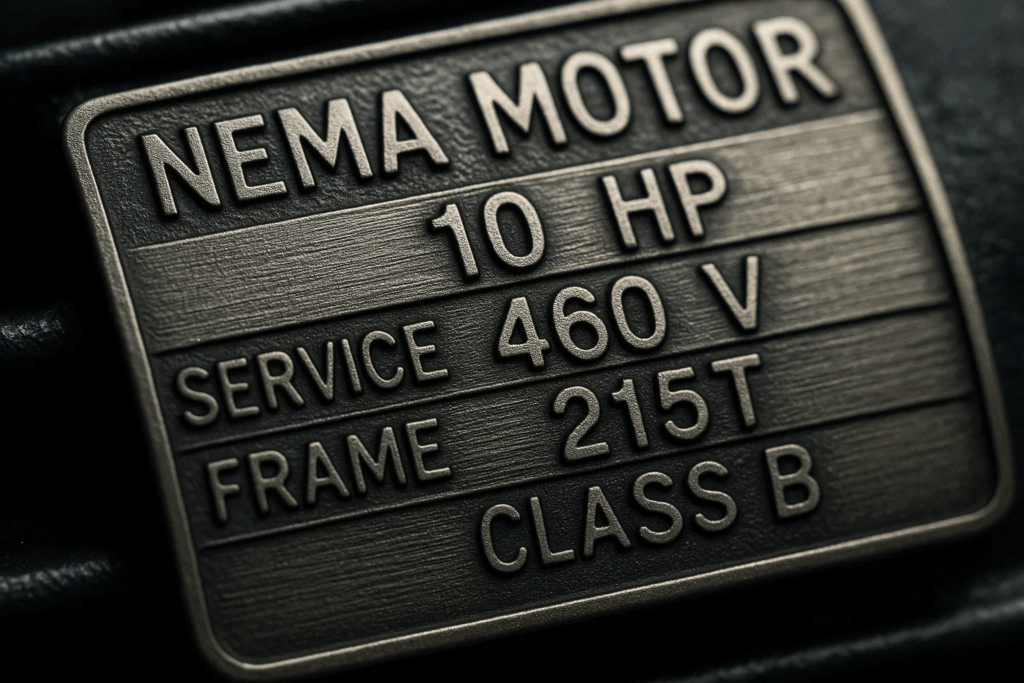

Check the nameplate: NEMA motors show horsepower (HP) and frame size (143T, 184T), while IEC motors display kilowatts (kW) and metric frame dimensions (80, 132).

Understanding the difference between NEMA and IEC motor standards empowers informed equipment decisions that impact operational efficiency, costs, and reliability. While NEMA motors offer robust construction with operational flexibility through service factors, IEC motors deliver superior energy efficiency and global compatibility.

Your optimal choice depends on application requirements, geographic location, and long-term operational strategy. North American facilities often benefit from NEMA’s robust design and local support infrastructure, while international operations leverage IEC’s efficiency and worldwide acceptance.

Regardless of your selection, comprehensive motor testing and validation ensures reliable performance and maximizes return on investment. Partner with experienced suppliers who understand both standards and can guide your selection based on specific application needs.

Ready to optimize your motor performance? Contact our experts for professional guidance on motor selection, testing, and maintenance solutions tailored to your specific applications.