Induction heating for shrink fitting delivers precision, speed, and efficiency in metal assembly applications. This advanced technology heats components to 150-300°C within seconds, enabling perfect interference fits while maintaining material integrity and reducing production costs by up to 70%.

Induction shrink fitting is a precision manufacturing process that uses electromagnetic induction to heat metal components between 150°C (302°F) and 300°C (572°F), causing thermal expansion that allows the insertion or removal of mating components. This advanced thermal expansion technique creates permanent interference fits without mechanical fasteners, adhesives, or welding.

The process leverages the fundamental principle of thermal expansion – when metals are heated, they expand proportionally to their coefficient of thermal expansion. By heating or cooling one component prior to assembly and allowing it to return to ambient temperature after assembly, the thermal expansion creates a joint that generally cannot be separated without reheating the assembly to reverse the process.

Unlike traditional “shrink wrap” packaging, the term “shrink fitting” refers to the contraction phase when the heated outer component cools and grips tightly around the inner part, creating an incredibly strong mechanical bond.

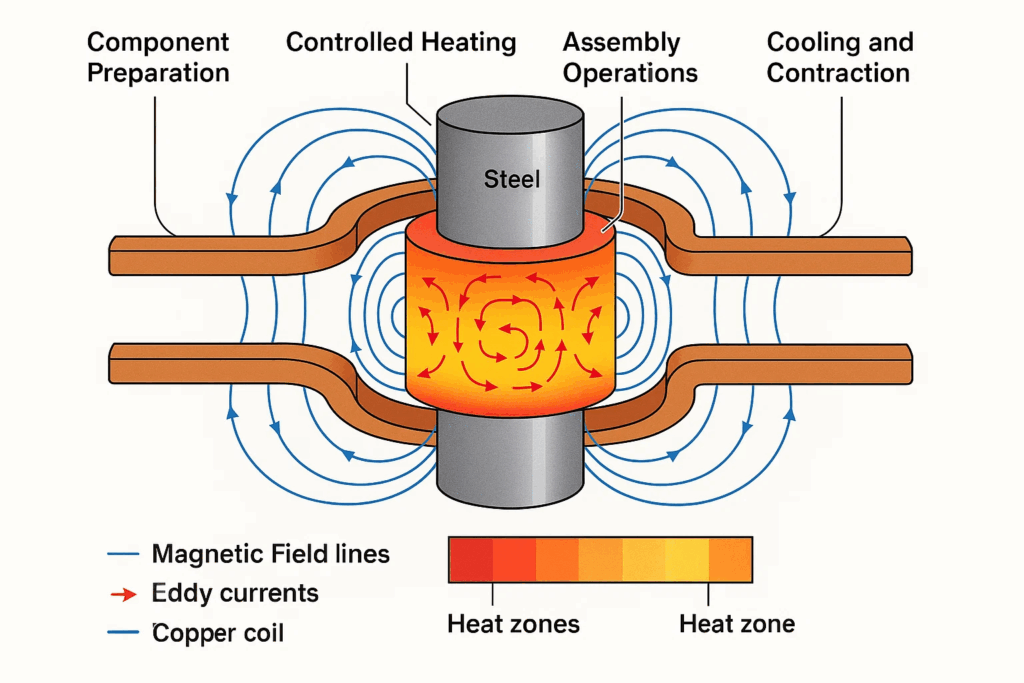

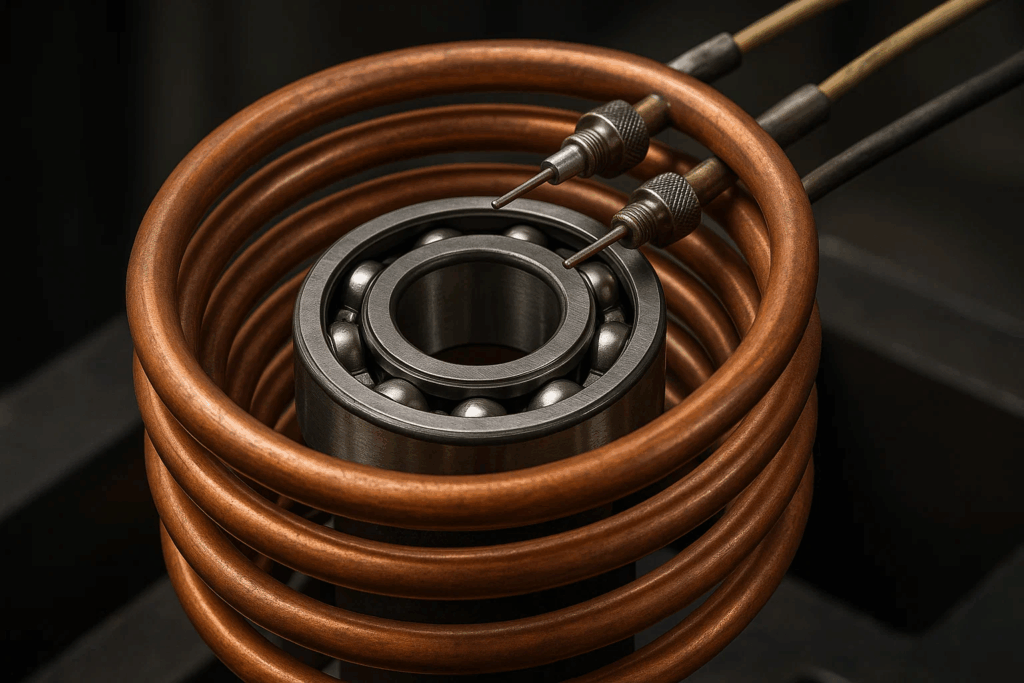

Induction heating works by inducing currents in the workpiece to heat it through ohmic heating. This is done by using an inductor, known as a coil, carrying alternating current and generating an alternating magnetic field. When electrically conductive materials are placed within this magnetic field, eddy currents flow through the metal, generating heat directly within the component.

This non-contact heating method offers unprecedented control over temperature distribution, heating rates, and process repeatability – making it ideal for precision shrink fitting applications.

The induction shrink fitting process follows a systematic approach that ensures consistent, reliable results across diverse applications.

Phase 1: Component Preparation

Phase 2: Controlled Heating

Phase 3: Assembly Operations

Phase 4: Cooling and Contraction

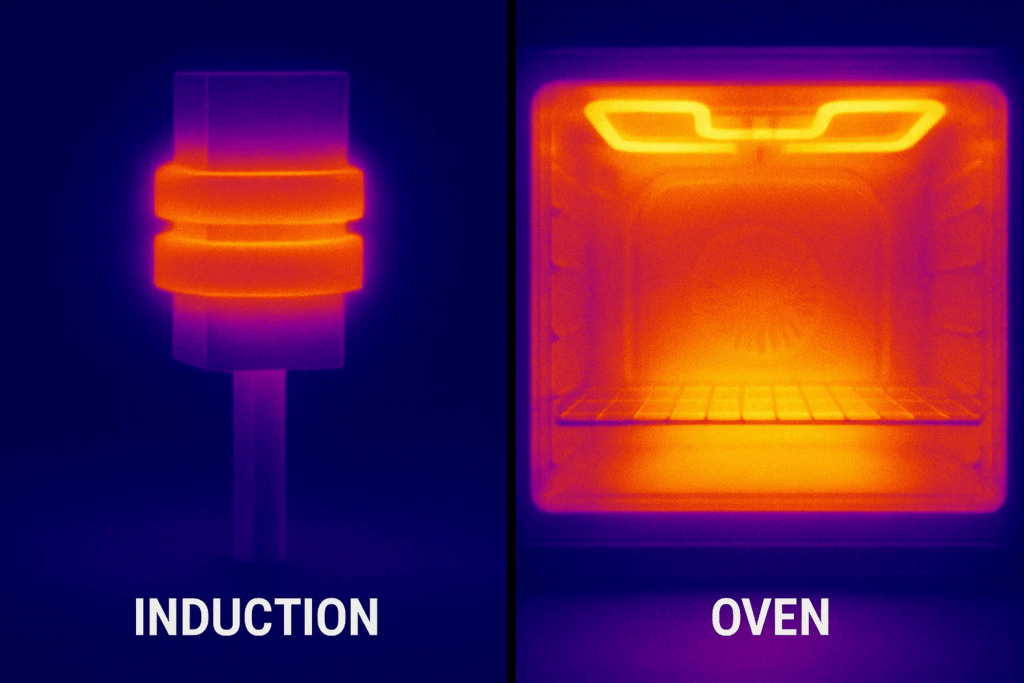

Processing with induction heat saves power and time. The complete component does not have to reach the desired temperature as it does when heating with an oven. Being able to selectively heat a zone allows for much quicker transfer of heat. This selective heating capability reduces cycle times from hours to minutes while maintaining precise temperature control.

The assembly window – the time available for component insertion – varies based on material properties, component mass, and ambient conditions. Successful shrink fitting requires careful coordination between heating cycles and assembly operations.

Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between 150°C (302°F) and 300°C (572°F). Typically the lower temperature range is used on metals such as aluminium and higher temperatures are used on metals such as low/medium carbon steels.

Aluminum Components:

Steel Components:

Copper and Brass:

The RF and MF heaters used for induction shrink fitting vary in power from a few kilowatts to many megawatts and depending on the component geometry/diameter/cross section can vary in frequency from 1 kHz to 200 kHz, although the majority of applications use the range between 1 kHz and 100 kHz.

Frequency Selection Criteria:

Power Requirements Calculation: Power selection depends on:

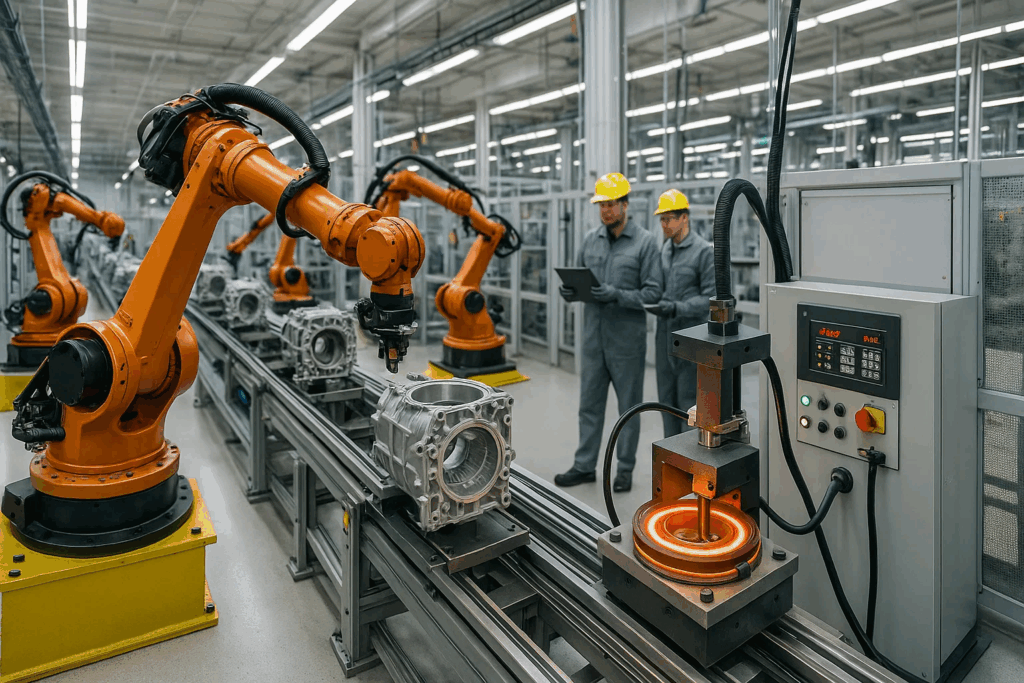

With induction, you can expect the same result every time. So once the process is determined, it is set and can be repeated over and over. This also makes it highly conducive to automated manufacturing processes. This repeatability stems from precise electromagnetic field control and advanced temperature monitoring systems.

Process Advantages:

Energy Efficiency Gains: Due to the heat being generated within the component, energy transfer is extremely efficient. The induction heater heats only the part not the atmosphere around it. This targeted heating approach delivers:

Production Efficiency: Induction shrink-fitting with EASYHEAT takes 45 minutes to heat the sample to the required temperature. The current oven process takes over two hours. Additional time savings include:

Metallurgical Integrity: The process avoids the changing of mechanical properties whilst allowing components to be worked. Low-temperature processing preserves:

Joint Quality:

Electric Motor Housing Assembly: Shrink fitting an automotive aluminum motor housing – Induction shrink-fitting is fast, presents significant energy savings over an electric oven, requires a more modest footprint than an oven and can be easily integrated into an automated process.

Modern electric vehicle manufacturing relies heavily on precision shrink fitting for:

Case Study: Camshaft Gear Assembly Heating a camshaft gear with a bore size of 1.630 inch to shrink fit over a steel shaft that has a diameter of 1.632 inch. A temperature of 500°F is required for the gear to expand 0.002 inch in order to slip over the shaft. This precision application demonstrates the capability to achieve interference fits with tolerances measured in thousandths of an inch.

Critical aerospace components require the highest levels of precision and reliability:

Bearing Installation: A multi-turn helical coil delivers uniform heat to the entire range of the bearing sizes in the transverse mode. Common applications include:

Heavy Industry Applications:

These powerful and robust induction generators are available with power ratings ranging from 5 to 150 kW and frequencies from 8 to 40 kHz. Selection factors include:

Application Requirements:

Environmental Considerations:

Internal (ID) Coils:

External (OD) Coils:

Multi-Turn Helical Coils: A multi-turn helical coil delivers uniform heat to the entire range of the bearing sizes in the transverse mode. Design advantages:

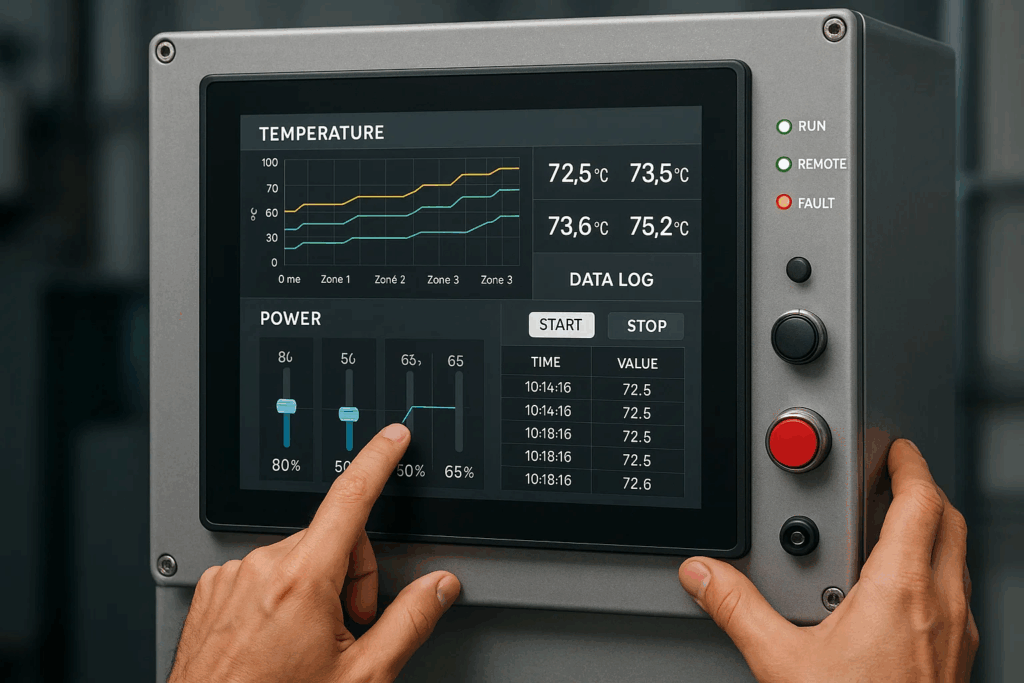

Modern induction heating systems incorporate sophisticated control features:

Since an induction generator’s output power can be controlled via a thermocouple or pyrometer, the generator can control the process to regulate and limit a component’s temperature automatically. This control ensures that an established set-point temperature is not exceeded.

Monitoring Technologies:

Electromagnetic Field Safety:

Thermal Safety Measures:

Electrical Safety:

Process Parameters Documentation:

Quality Assurance Methods:

Electric Oven Heating: Parts are placed in an industrial oven and heated slowly until thermal expansion allows for assembly.

Limitations:

Torch Heating: The customer was using a torch, which can lead to inconsistent part quality.

Disadvantages:

Oil Bath Heating: Issues include:

Induction heating offers a faster, cleaner, and more automatable alternative to these older approaches. It applies focused heat directly into the part, making it incredibly efficient for precision fits and repeatable processes.

Quantified Performance Improvements:

Problem: Uneven temperature distribution across component Causes:

Solutions:

Problem: Insufficient time for component insertion Root Causes:

Corrective Actions:

Problem: Inconsistent joint quality and assembly failures

Common Issues:

Best Practices:

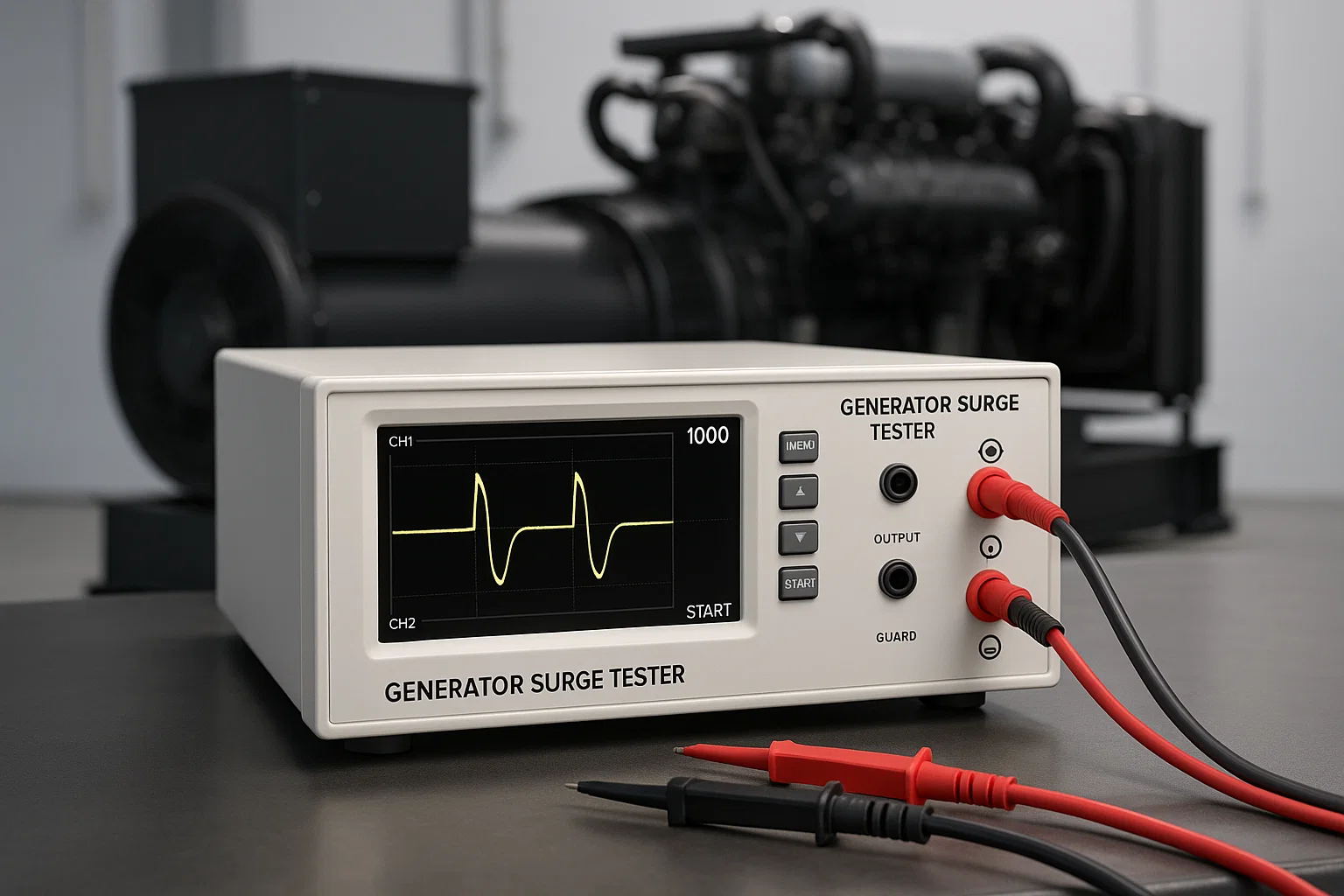

Understanding how induction heaters work is crucial for troubleshooting system problems. Common equipment issues include:

Regular maintenance following proper maintenance protocols ensures optimal system performance and longevity.

The integration of induction heating systems with Industry 4.0 technologies is revolutionizing shrink fitting operations:

IoT Connectivity:

Advanced Analytics:

Enhanced Power Electronics: Modern induction heating equipment benefits from advances in SiC and GaN semiconductors, delivering:

Advanced Coil Technologies:

Electric Vehicle Manufacturing: The rapid growth of electric vehicle production is driving demand for precision shrink fitting in:

Renewable Energy Sector: Wind turbine and solar equipment manufacturing require specialized shrink fitting for:

Understanding induction heating applications in renewable energy reveals the expanding role of this technology.

Component Analysis:

Process Requirements:

Successful induction shrink fitting implementation requires collaboration with experienced equipment manufacturers who understand:

For complex applications, consider manufacturers with proven expertise in industrial induction heating solutions and comprehensive technical support.

Induction heating for shrink fitting represents a transformative technology that delivers unmatched precision, efficiency, and reliability in metal assembly applications. With heating capabilities from 150-300°C achieved in seconds rather than hours, manufacturers can realize significant improvements in production throughput, energy consumption, and quality consistency.

The technology’s ability to provide localized, controlled heating while maintaining material integrity makes it ideal for critical applications in automotive, aerospace, and industrial equipment manufacturing. As smart manufacturing technologies continue to evolve, induction shrink fitting systems will become increasingly automated and integrated with advanced process control systems.

Strategic Recommendations:

Understanding the principles and applications of smart induction heating technology positions manufacturers to capitalize on this advanced assembly method’s full potential.

For organizations considering induction shrink fitting implementation, the combination of energy savings, quality improvements, and production efficiency gains typically provides return on investment within 12-18 months, making this technology an excellent strategic investment for competitive manufacturing operations.

Related Resources:

Contact our technical experts today to discuss your specific shrink fitting application requirements and discover how induction heating technology can transform your manufacturing operations.