Are you struggling to understand the role of Hi-pot testing in modern digital surge testers? You’re not alone. Many electrical professionals find themselves confused about how these two critical testing methods work together in today’s advanced testing equipment. Without proper understanding, you risk inadequate testing protocols, potential equipment failures, and costly downtime that could have been prevented. This comprehensive guide will demystify Hi-pot functionality in digital surge testers, explain their synergistic relationship, and help you maximize your electrical testing effectiveness.

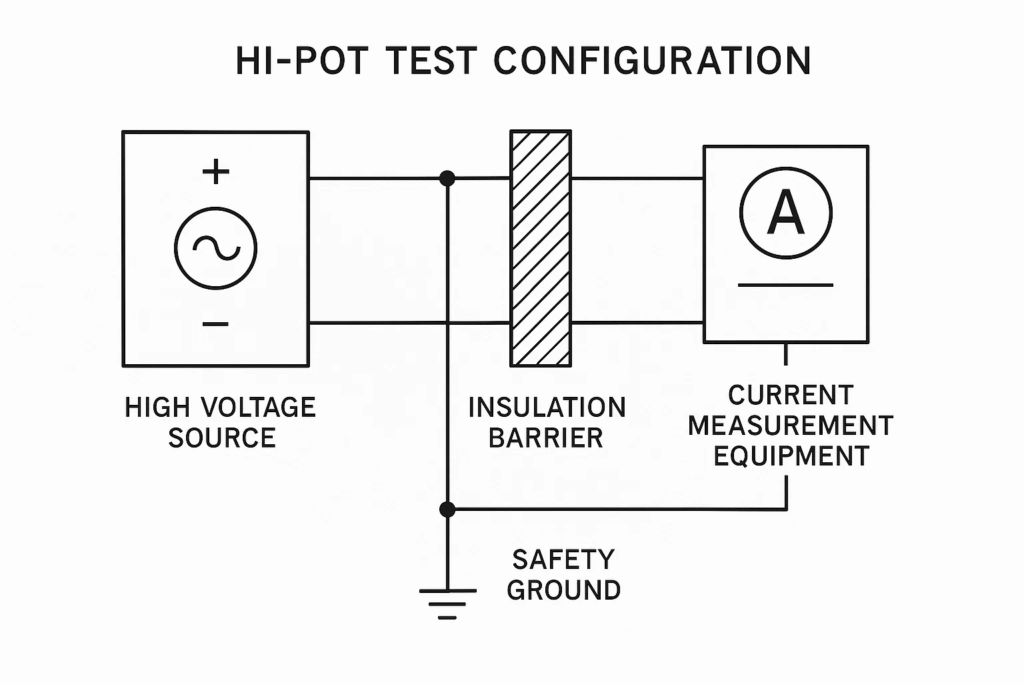

Hi-pot testing, short for high potential testing, represents one of the most critical non-destructive electrical tests used to evaluate insulation integrity in electrical equipment. Also known as dielectric withstand testing or overvoltage testing, this method applies voltages significantly higher than normal operating levels to verify that insulation systems can withstand electrical stress without breaking down.

The primary purpose of Hi-pot testing involves stress-testing insulation barriers between conductive components and ground, or between different conductive elements within electrical systems. Unlike other testing methods that focus on specific fault types, Hi-pot testing provides a comprehensive evaluation of overall insulation health.

Key characteristics of Hi-pot testing include:

The test works by applying high voltage across insulation materials and measuring any resulting current flow. Healthy insulation should allow only minimal current passage, while degraded or damaged insulation will show increased leakage current, indicating potential failure points.

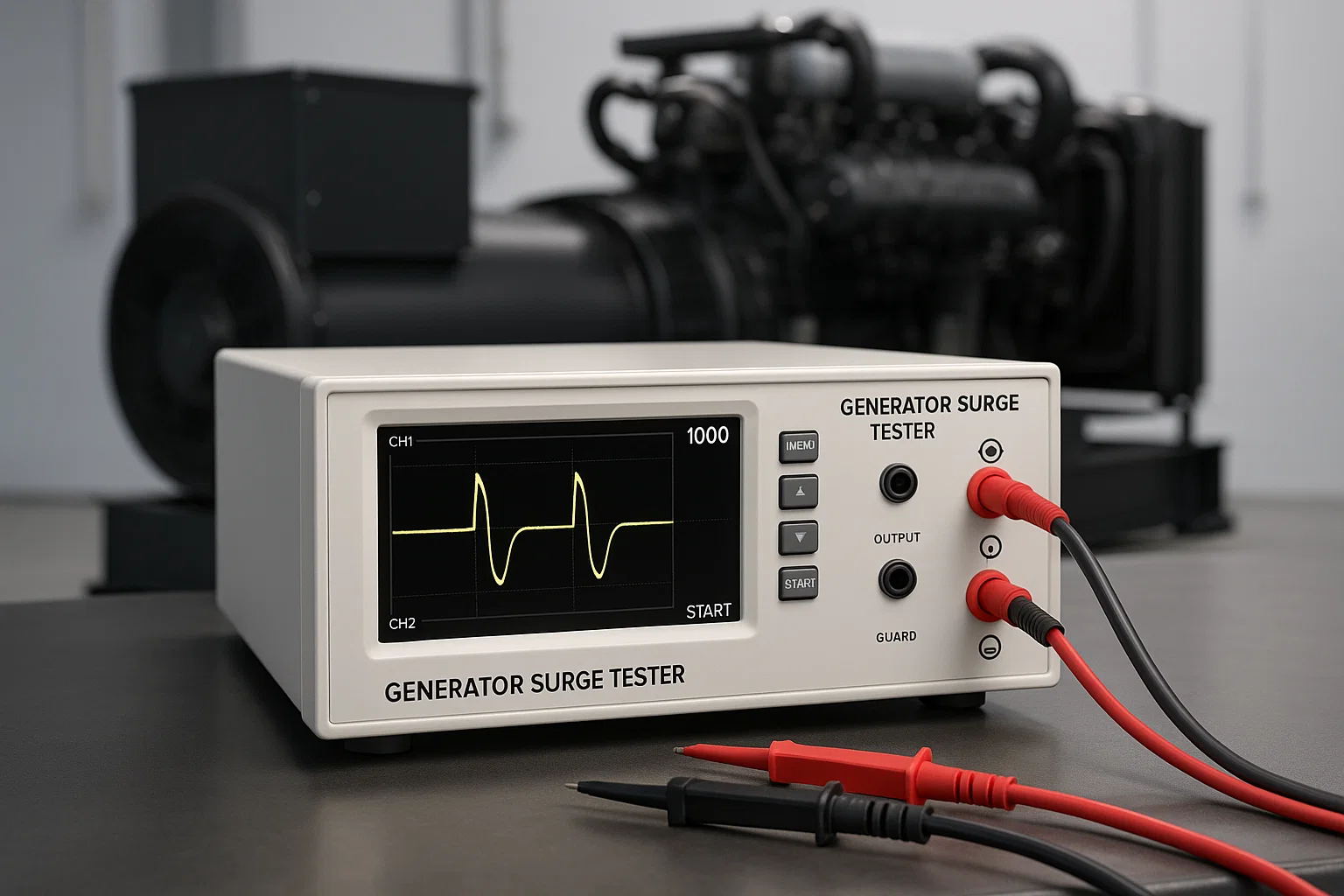

Digital surge testers represent the evolution of traditional impulse testing equipment, incorporating advanced microprocessor control, digital signal processing, and sophisticated analysis algorithms. These modern instruments provide unprecedented accuracy and reliability in detecting winding insulation faults.

Modern digital surge testers integrate several key technologies:

High-Voltage Pulse Generation System: Creates controlled voltage pulses through capacitor discharge circuits, allowing precise control over pulse characteristics and energy levels.

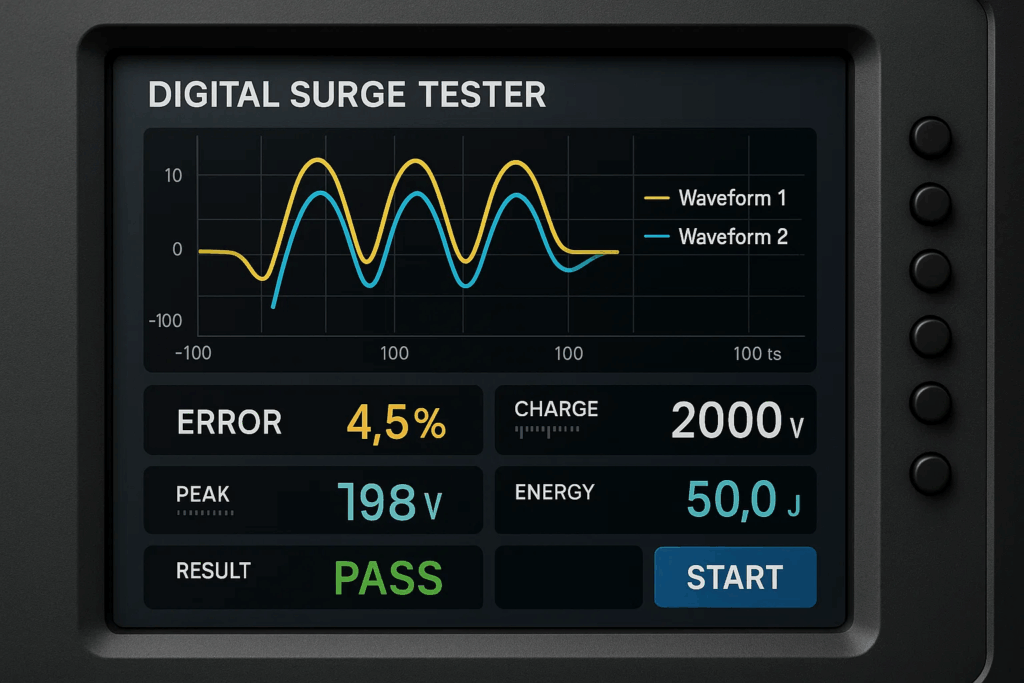

Advanced Waveform Analysis: Digital signal processing capabilities enable detailed waveform comparison and mathematical analysis, including percentage wave difference calculations and error area ratios.

Microprocessor Control: Embedded industrial computers provide intuitive touchscreen interfaces, automated testing sequences, and comprehensive data management capabilities.

Safety Integration: Built-in safety features including lead energization warnings, zero-start locks, and automatic discharge circuits ensure operator protection during testing procedures.

The surge testing process involves charging a high-voltage capacitor and discharging it through the equipment under test. This creates a decaying oscillating waveform that reveals information about winding integrity and insulation condition.

Critical fault detection capabilities include:

The digital analysis compares waveforms either phase-to-phase or pulse-to-pulse, calculating percentage differences that indicate insulation health. When differences exceed predetermined thresholds, the system flags potential problems requiring further investigation.

Understanding the fundamental differences between Hi-pot and surge testing is crucial for implementing effective electrical testing programs. While both methods evaluate insulation integrity, they target different types of faults and use distinct testing approaches.

Surge Testing Specialization:

Hi-pot Testing Specialization:

The voltage application methods differ significantly between these testing approaches:

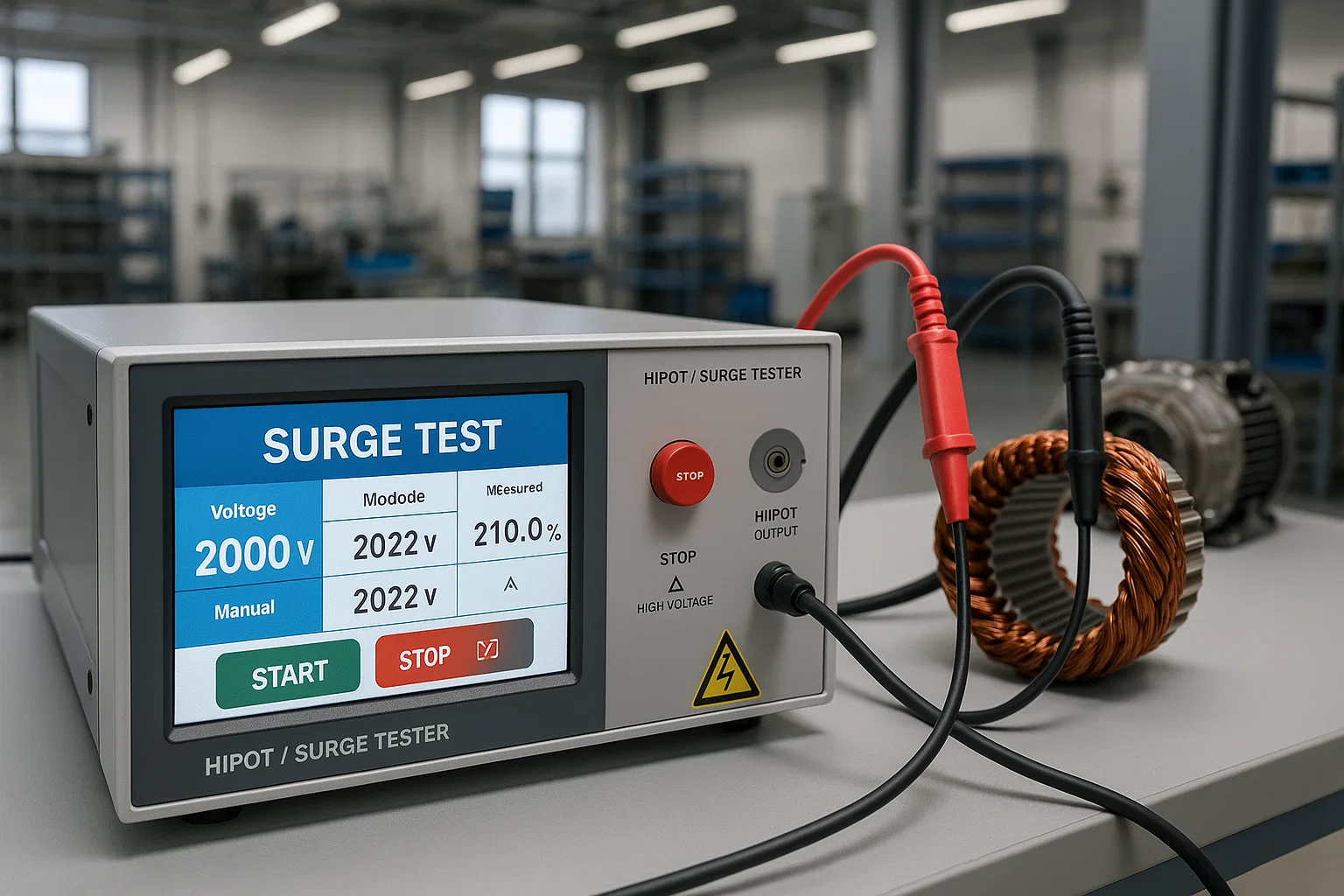

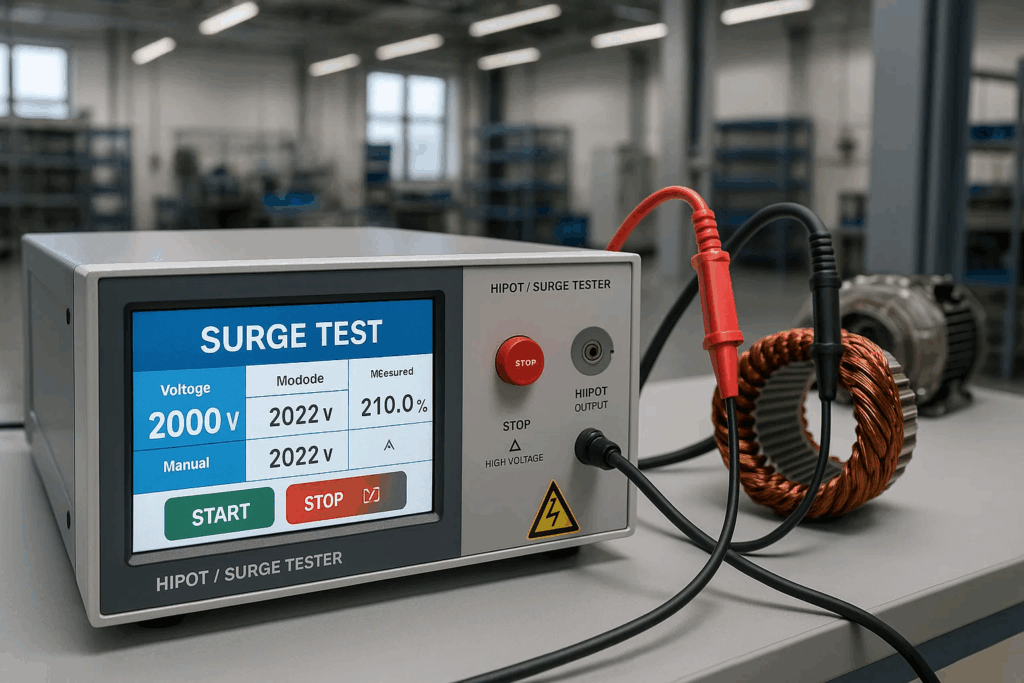

Surge Testing Method: Applies high-voltage pulses (typically microseconds duration) at voltages 2-4 times normal operating levels. The energy content remains low despite high voltage, making the test non-destructive to healthy insulation.

Hi-pot Testing Method: Applies sustained high voltage (typically 60 seconds) at levels 1.5-2 times operating voltage plus safety margin. The continuous application allows detection of time-dependent insulation failures.

Each testing method excels at detecting specific fault types:

Surge testing advantages:

Hi-pot testing advantages:

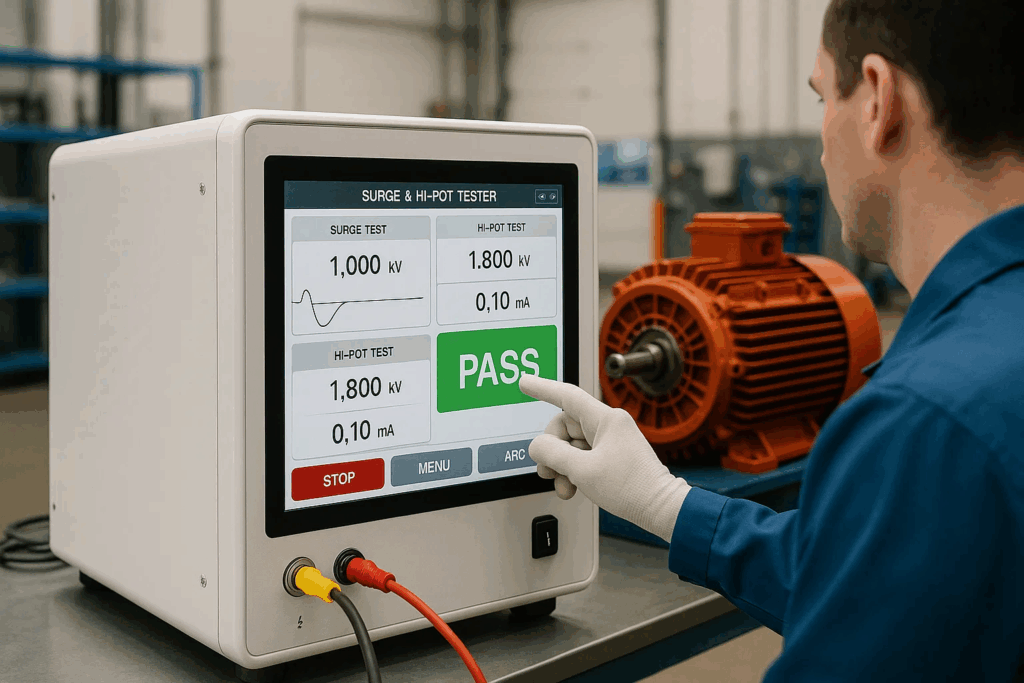

Modern digital surge testers that incorporate Hi-pot testing capabilities offer significant advantages over standalone testing equipment. This integration provides comprehensive insulation evaluation while streamlining testing procedures and reducing equipment costs.

Combined testing platforms deliver complete insulation assessment by addressing all major failure modes:

Enhanced Diagnostic Capability: The combination provides detection of turn-to-turn faults through surge testing and ground insulation evaluation through Hi-pot testing, ensuring no potential failure mode goes undetected.

Complementary Analysis: Surge testing may reveal winding problems that don’t affect ground insulation, while Hi-pot testing can identify ground faults that don’t impact turn-to-turn insulation. Together, they provide complete coverage.

Sequential Testing Protocol: Recommended testing sequence involves insulation resistance measurement first, followed by surge testing, then Hi-pot testing. This progression allows detection of obvious faults before applying higher stress levels.

Integrated testing solutions offer substantial operational benefits:

Single Equipment Setup: Eliminates need for multiple test stations and reduces setup time, cable connections, and potential for operator error during equipment changes.

Unified Data Management: Comprehensive test records combining both surge and Hi-pot results provide complete equipment history and trending capabilities for predictive maintenance programs.

Streamlined Procedures: Automated testing sequences reduce testing time and ensure consistent application of testing protocols across different operators and facilities.

Combined testing platforms provide significant economic advantages:

Reduced Capital Investment: Single integrated unit costs less than purchasing separate surge and Hi-pot testers, while providing equivalent or superior capabilities.

Lower Training Requirements: Operators need training on only one system interface rather than multiple different testing platforms, reducing training time and costs.

Maintenance Efficiency: Single equipment maintenance schedule and spare parts inventory simplify facility management and reduce operational overhead.

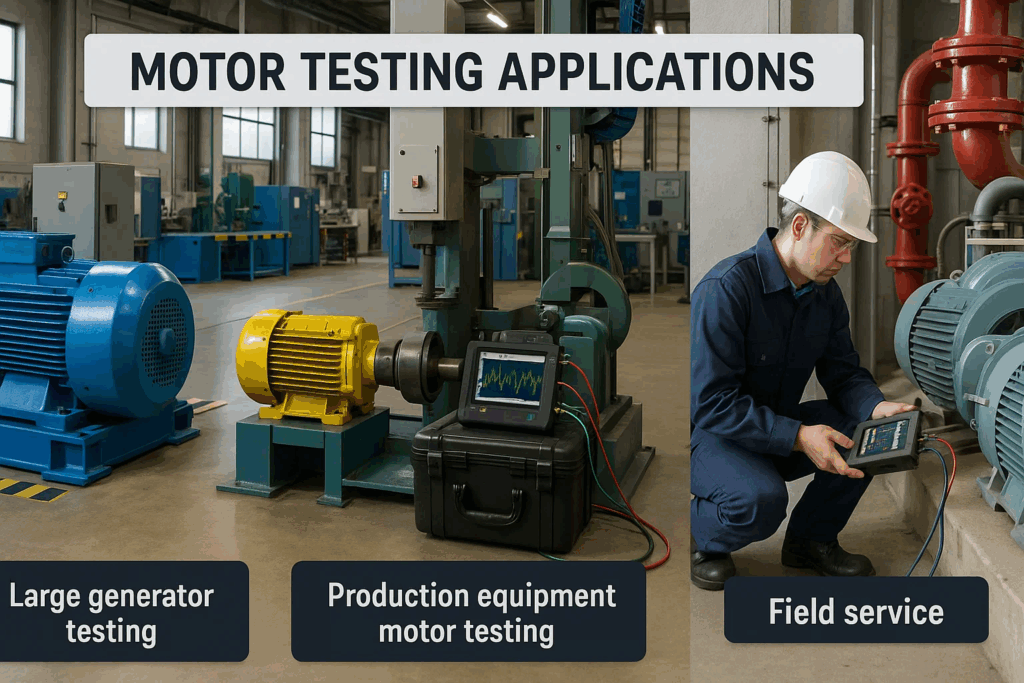

Combined Hi-pot and surge testing finds extensive application across various industrial sectors, providing critical insulation assessment for motors, generators, transformers, and other electrical equipment.

Production Line Integration: Digital surge testers with Hi-pot capabilities serve as essential quality control tools in motor manufacturing, ensuring newly produced units meet insulation standards before shipment.

Rewind Verification: After motor rewinding operations, combined testing verifies both winding integrity and ground insulation quality, preventing defective units from returning to service.

Acceptance Testing: New motor installations require comprehensive testing to verify manufacturer specifications and establish baseline measurements for future comparison.

Scheduled Testing Intervals: Regular surge and Hi-pot testing enables detection of developing insulation problems before they cause equipment failure, allowing planned maintenance rather than emergency repairs.

Trending Analysis: Historical test data reveals insulation degradation patterns, enabling prediction of remaining equipment life and optimal replacement timing.

Condition-Based Decisions: Test results guide maintenance decisions, helping determine whether equipment can continue operation, requires immediate attention, or needs replacement.

Troubleshooting Support: Portable combined testing equipment enables field technicians to perform comprehensive insulation evaluation at equipment installation sites.

Emergency Response: When motor failures occur, combined testing helps identify root causes and verify repair effectiveness before returning equipment to service.

Commissioning Activities: New installations require thorough testing to ensure proper installation and verify equipment readiness for operation.

Different industries have specific testing requirements that benefit from combined testing capabilities:

Power Generation: Generators and large motors require both surge testing for turn-to-turn faults and Hi-pot testing for ground insulation verification, especially important given the critical nature of power generation equipment.

Manufacturing: Production equipment motors need regular testing to prevent unplanned downtime, with combined testing providing comprehensive assessment in minimal time.

Transportation: Railway and marine applications require reliable motor testing capabilities for critical propulsion and control systems.

Selecting appropriate combined surge and Hi-pot testing equipment requires careful consideration of application requirements, testing capabilities, and operational factors.

Voltage Range Requirements: Equipment must provide adequate voltage ranges for both surge testing (typically up to 25-40kV) and Hi-pot testing (typically up to 6-15kV DC) to handle various motor voltage ratings.

Current Measurement Accuracy: Hi-pot testing requires precise current measurement capabilities, typically with microampere resolution and appropriate overload protection to prevent nuisance trips.

Waveform Analysis Capabilities: Advanced digital signal processing enables sophisticated waveform comparison algorithms, including percentage wave difference, error area ratio, and other mathematical analysis tools.

User Interface Design: Modern touchscreen interfaces should provide intuitive operation, comprehensive data display, and easy navigation through testing procedures.

Operator Protection Systems: Essential safety features include lead energization warnings, zero-start locks, automatic discharge circuits, and emergency stop capabilities.

Equipment Protection: Overcurrent protection, automatic test termination, and controlled voltage ramping prevent damage to equipment under test and testing instrumentation.

Environmental Considerations: Testing equipment must operate reliably in various environmental conditions, including temperature extremes, humidity, and electromagnetic interference.

Test Record Storage: Unlimited storage capacity ensures complete test history retention for trending analysis and regulatory compliance requirements.

Report Generation: Automated report generation capabilities provide professional documentation for maintenance records and quality assurance programs.

Connectivity Options: USB, Ethernet, and wireless connectivity enable integration with facility management systems and remote data access.

Technical Support: Comprehensive technical support including installation assistance, operator training, and ongoing troubleshooting support ensures optimal equipment utilization.

Calibration Services: Regular calibration services maintain testing accuracy and ensure compliance with applicable standards and regulations.

Upgrade Capability: Software upgrade capability extends equipment life and adds new features as testing requirements evolve.

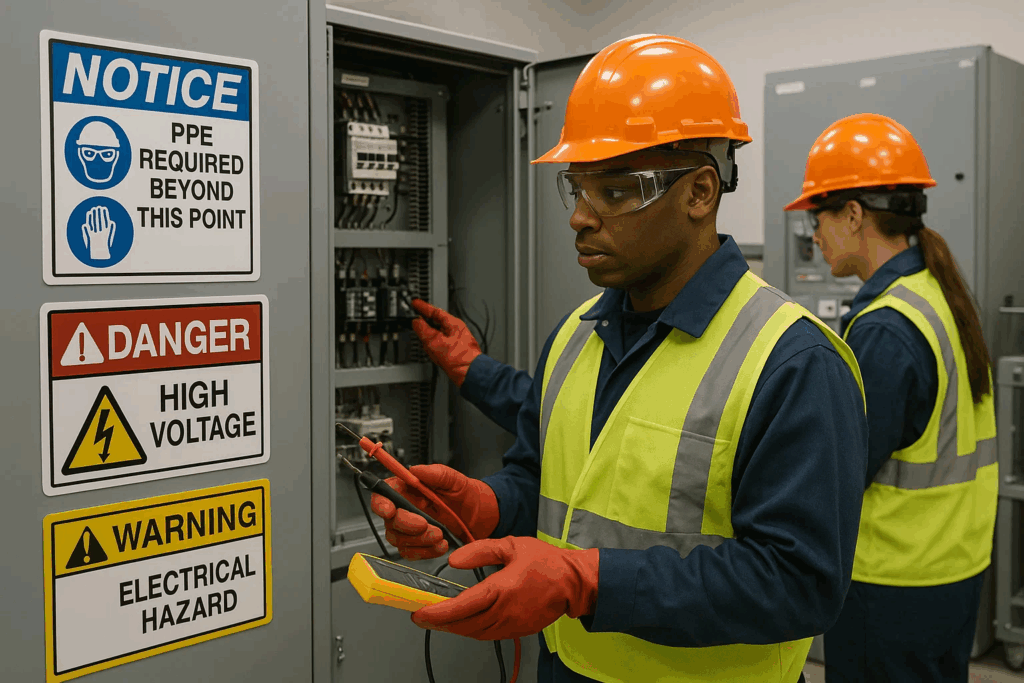

Working with high-voltage testing equipment requires strict adherence to safety protocols and best practices to protect operators and prevent equipment damage.

Training Requirements: All operators must receive comprehensive training on high-voltage safety procedures, equipment operation, and emergency response protocols before working with testing equipment.

Personal Protective Equipment: Appropriate PPE including insulated gloves, safety glasses, and arc-rated clothing provides essential protection during testing operations.

Work Area Preparation: Establish clear work boundaries, remove unnecessary personnel, and ensure adequate lighting and ventilation in testing areas.

Pre-Test Inspections: Verify test lead integrity, check grounding connections, and confirm proper equipment setup before applying high voltage.

Controlled Voltage Application: Use gradual voltage ramping rather than sudden application to prevent insulation damage and ensure operator safety.

Automatic Safety Features: Modern equipment includes automatic discharge circuits, overcurrent protection, and emergency stop capabilities that must be verified functional before testing.

Electrical Isolation: Ensure proper isolation of equipment under test from other electrical systems to prevent inadvertent energization of connected equipment.

Contamination Prevention: Clean testing environment prevents contamination that could affect test results or create safety hazards.

Documentation Requirements: Maintain detailed safety documentation including procedures, training records, and incident reports as required by regulatory standards.

Incident Response: Establish clear procedures for electrical incidents including emergency contact information, first aid procedures, and equipment isolation methods.

Equipment Malfunction: Proper troubleshooting procedures help identify and resolve equipment problems safely without exposing operators to unnecessary risks.

Regular Safety Reviews: Periodic safety training updates and procedure reviews ensure continued awareness of proper safety practices.

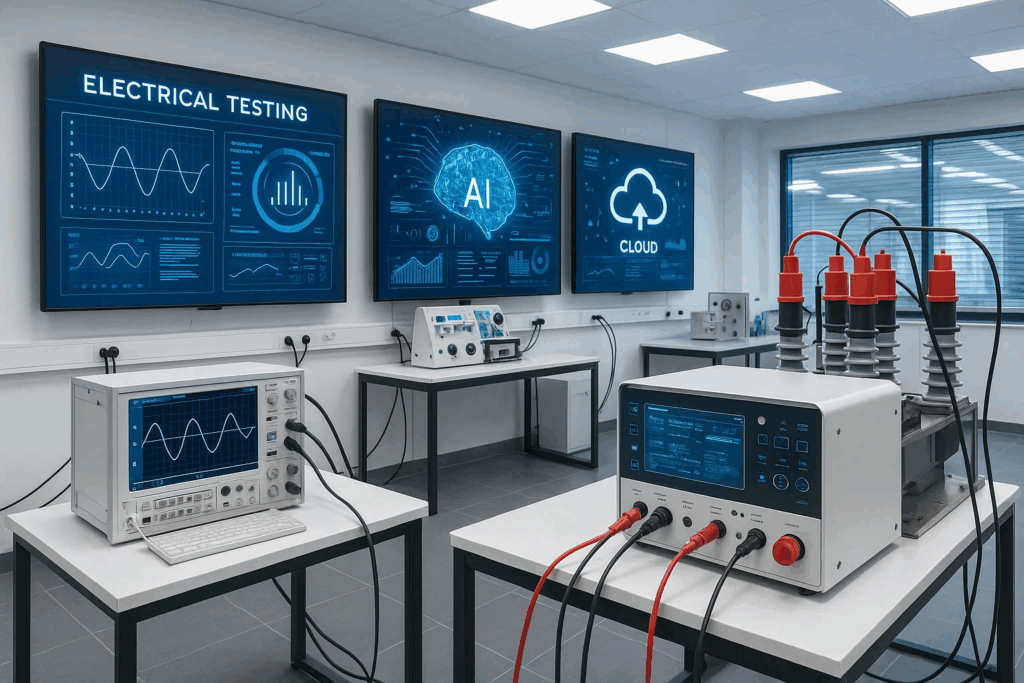

The evolution of electrical testing technology continues advancing toward more sophisticated, automated, and intelligent testing solutions that enhance both capability and ease of use.

Artificial Intelligence Integration: Machine learning algorithms increasingly analyze test results, identifying subtle patterns that indicate developing problems before they become apparent through traditional analysis methods.

Cloud Connectivity: Internet-connected testing equipment enables remote monitoring, centralized data management, and expert consultation capabilities regardless of geographic location.

Automated Decision Making: Advanced algorithms provide automated pass/fail determinations and maintenance recommendations based on comprehensive analysis of test results and historical trending data.

Intuitive Interfaces: Touchscreen interfaces continue evolving toward smartphone-like operation with gesture control, voice commands, and augmented reality guidance for complex procedures.

Simplified Operation: Automated testing sequences reduce operator decision-making requirements while ensuring consistent application of proper testing protocols.

Real-Time Guidance: Interactive help systems provide context-sensitive assistance and training during testing operations.

Facility Management Systems: Testing equipment increasingly integrates with computerized maintenance management systems (CMMS) and enterprise resource planning (ERP) systems for seamless data flow.

Predictive Analytics: Advanced analytics platforms combine testing data with operational parameters to provide comprehensive equipment health assessment and failure prediction.

Remote Capabilities: Internet connectivity enables remote testing support, expert consultation, and centralized equipment management across multiple facilities.

Standards Development: Testing standards continue evolving to address new insulation materials, equipment designs, and application requirements in modern electrical systems.

Automated Compliance: Testing equipment increasingly provides automated compliance verification and documentation generation to simplify regulatory adherence.

Global Harmonization: International standards harmonization simplifies equipment selection and ensures consistent testing practices across different regions and industries.

Hi-pot functionality in digital surge testers represents a powerful combination that delivers comprehensive insulation evaluation while maximizing operational efficiency and cost-effectiveness.

Essential action items for implementation:

Modern electrical systems demand sophisticated testing approaches that keep pace with advancing technology and increasing reliability requirements. Combined Hi-pot and surge testing capabilities in digital platforms provide the comprehensive evaluation necessary to maintain equipment reliability, prevent costly failures, and ensure operator safety in today’s demanding industrial environments.

Related Resources:

About Vivid Metrawatt Global: Leading manufacturer of advanced electrical testing equipment including digital surge testers with integrated Hi-pot capabilities, serving industries worldwide with precision testing solutions.

Hi-pot functionality in digital surge testers represents a transformative advancement in electrical testing technology, delivering unprecedented comprehensive insulation evaluation capabilities. Throughout this guide, we’ve explored how this powerful combination addresses the complex challenges facing modern electrical professionals while maximizing operational efficiency and cost-effectiveness.

The integration of Hi-pot testing within digital surge testing platforms fundamentally changes how we approach electrical insulation assessment. Unlike traditional standalone testing methods, combined systems provide complete fault detection coverage, addressing both turn-to-turn insulation failures through surge testing and ground insulation degradation through Hi-pot evaluation. This comprehensive approach ensures no potential failure mode goes undetected, significantly reducing the risk of unexpected equipment failures and costly downtime.

Technical advantages we’ve covered include:

Successful implementation of combined Hi-pot and surge testing requires careful attention to several critical factors. Equipment selection must balance technical capabilities with operational requirements, ensuring adequate voltage ranges, measurement accuracy, and user interface design. Safety protocols remain paramount, requiring comprehensive operator training and adherence to established procedures for high-voltage testing operations.

Organizations achieving maximum benefit focus on:

The electrical testing industry continues evolving toward more sophisticated, intelligent solutions that enhance both capability and ease of use. Artificial intelligence integration, cloud connectivity, and automated decision-making represent the next frontier in testing technology, promising even greater insights and operational efficiency.

As electrical systems become increasingly complex and reliability requirements continue rising, combined testing solutions will play an essential role in maintaining equipment health and preventing failures. The investment in modern testing technology pays dividends through reduced downtime, extended equipment life, and enhanced safety performance.

For electrical professionals considering upgrading their testing capabilities, the evidence strongly supports investing in combined Hi-pot and surge testing solutions. The comprehensive evaluation capabilities, operational efficiencies, and cost advantages make these systems essential tools for modern electrical maintenance and quality assurance programs.

Take action today by:

The future of electrical reliability depends on embracing advanced testing technologies that provide the comprehensive evaluation necessary to maintain equipment health and prevent costly failures. Combined Hi-pot and surge testing represents not just an improvement in testing capability, but a fundamental advancement in how we approach electrical system reliability and safety.