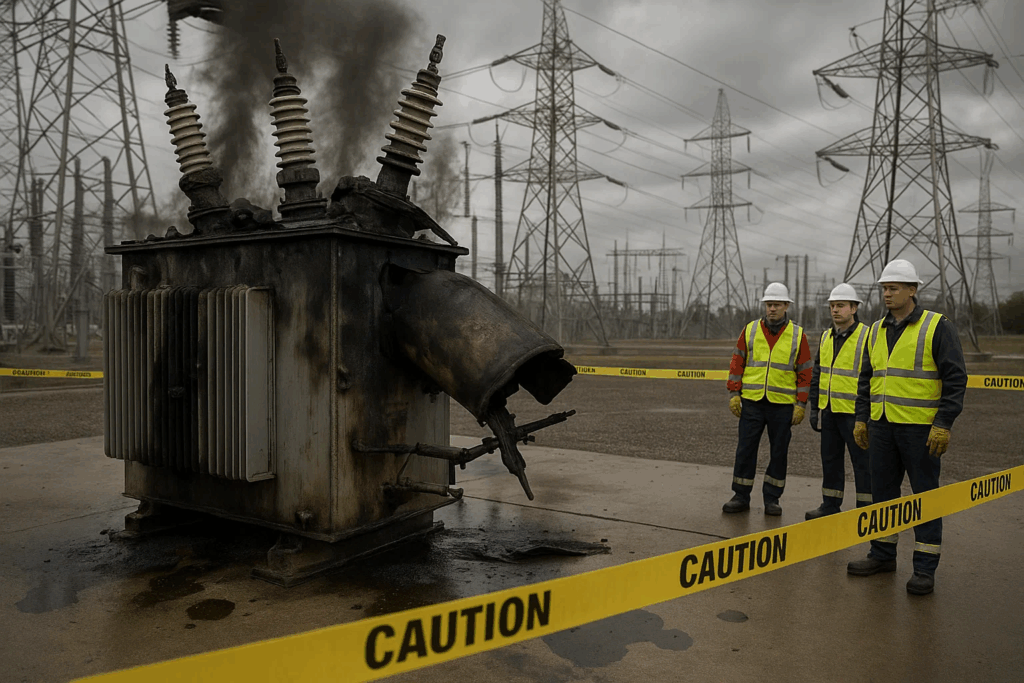

Electrical insulation failures account for over 60% of unexpected equipment breakdowns in high-voltage systems, causing operational disruptions and safety hazards. Partial discharge testing identifies these developing faults years before catastrophic failure occurs, detecting microscopic electrical breakdowns invisible to conventional testing methods. This advanced diagnostic technique monitors insulation health in transformers, motors, cables, and switchgear, enabling condition-based maintenance that prevents failures, extends equipment lifespan, and eliminates unplanned downtime.

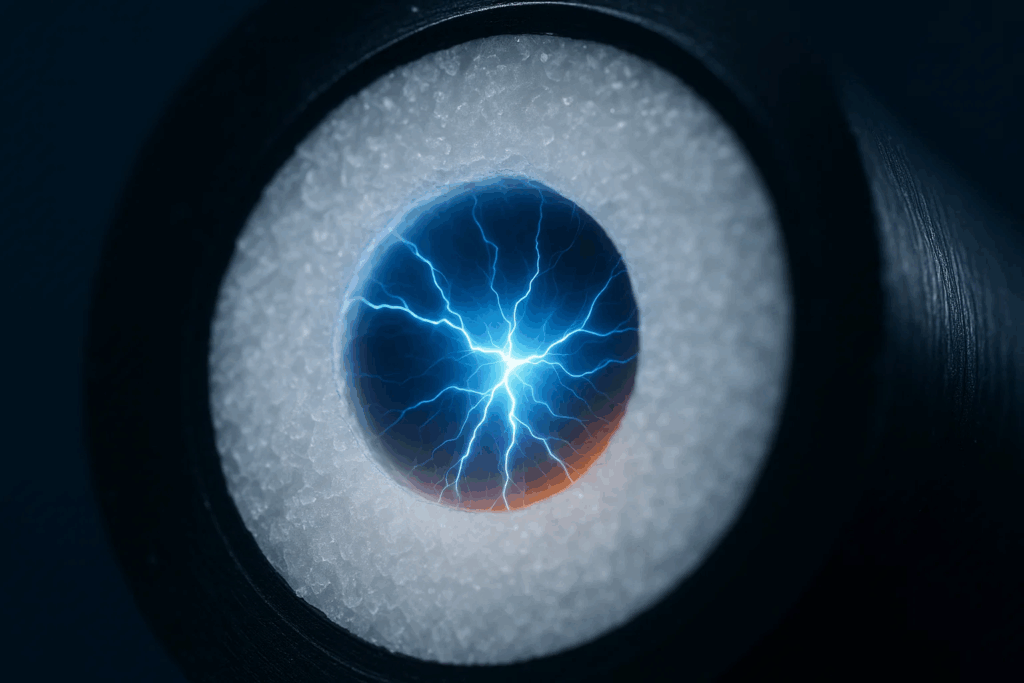

Partial discharge represents localized dielectric breakdown occurring within electrical insulation systems when voltage stress exceeds the breakdown strength of small imperfections, voids, or contaminated areas. Unlike complete insulation failure that creates short circuits, partial discharges affect only limited portions of the insulation, repeatedly occurring without immediately causing equipment failure.

Electrical breakdown mechanisms in insulation materials follow predictable patterns governed by electric field distribution and material properties. When voltage gradient within a void or defect exceeds the breakdown threshold, electrons accelerate through the space creating a small electrical discharge. This discharge partially relieves the local electric stress temporarily before voltage reapplies and the cycle repeats.

Energy release characteristics distinguish partial discharge from complete breakdown. Each discharge event releases electromagnetic energy measured in picocoulombs, generating detectable electrical pulses, acoustic emissions, light, and chemical byproducts. Modern testing equipment captures these signatures, revealing insulation condition through sophisticated pattern analysis.

Progressive degradation occurs as repeated discharge events gradually erode insulation materials. The discharge plasma chemically attacks surrounding material creating larger voids, increased contamination, and expanded damage zones. This progressive deterioration eventually connects defect sites creating paths for complete insulation failure.

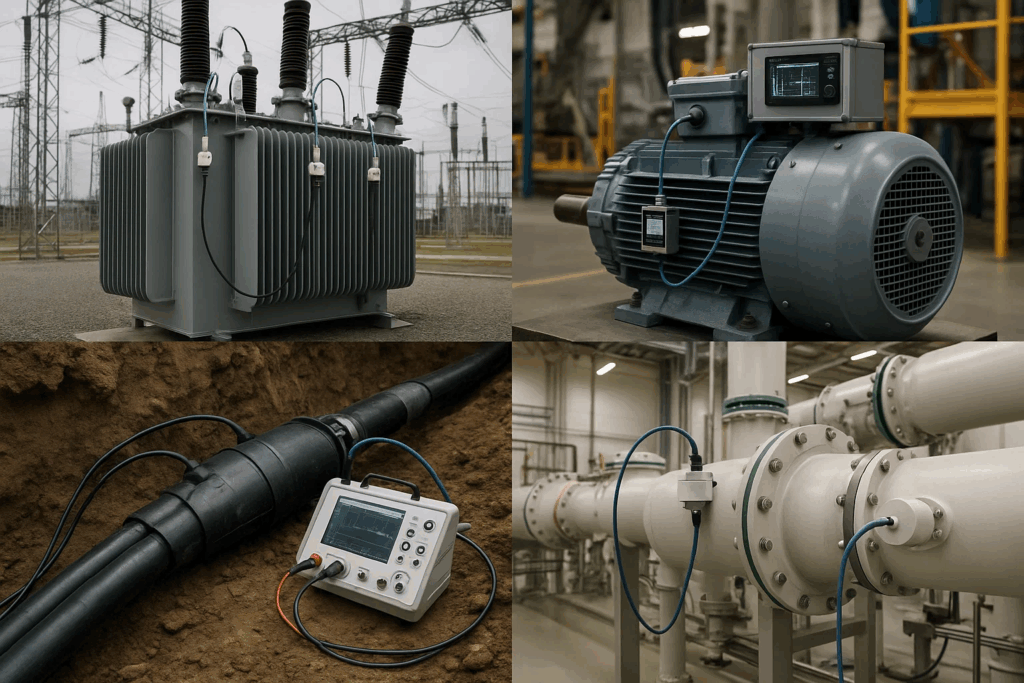

Transformer insulation systems contain numerous potential discharge sites including oil-paper interfaces, winding insulation layers, bushing assemblies, and tap changer contacts. Manufacturing imperfections, moisture ingress, and aging processes create conditions supporting discharge activity that accelerates under operational stress.

Motor and generator windings experience partial discharge at turn-to-turn insulation boundaries, slot discharge along stator surfaces, and end-winding corona from high electric field concentrations. The combination of electrical, thermal, and mechanical stresses in rotating machines makes comprehensive motor winding testing essential for reliability.

Cable systems develop partial discharge at splice interfaces, termination stress cones, and within aged insulation containing moisture or contamination. Underground cables experience unique challenges from environmental exposure making regular monitoring critical for grid reliability.

Switchgear components including circuit breakers, disconnectors, and bus connections generate discharge activity from contact deterioration, insulator surface contamination, and gas breakdown in enclosed equipment. Gas-insulated switchgear requires specialized detection approaches addressing the unique characteristics of SF6 or alternative gas insulation.

Partial discharge detection provides warning of developing insulation problems months or years before conventional testing reveals issues. This early warning capability transforms maintenance from reactive repairs after failure to planned interventions preventing service disruptions.

Detecting turn-to-turn faults in motor windings exemplifies PD testing advantages over traditional methods. While surge testing effectively identifies severe turn-to-turn failures, partial discharge monitoring detects incipient deterioration before damage progresses to surge-detectable levels, providing even earlier intervention opportunities.

Transformer degradation monitoring through continuous partial discharge measurement tracks insulation aging trends, correlating discharge patterns with dissolved gas analysis results. Combined diagnostics provide comprehensive condition assessment guiding maintenance decisions and replacement planning.

Trending and prediction capabilities emerge from longitudinal partial discharge data collection. Establishing baseline measurements and monitoring changes over time enables predictive maintenance scheduling based on actual equipment condition rather than arbitrary time intervals.

Preventing catastrophic failures protects personnel from explosive transformer ruptures, motor fires, and cable flashovers. Partial discharge testing identifies high-risk conditions enabling proactive safety measures before hazardous failures occur.

Arc flash hazard reduction follows from improved equipment reliability and planned maintenance during scheduled outages rather than emergency repairs. Condition-based interventions eliminate many situations creating arc flash exposure during troubleshooting and repair activities.

Environmental protection benefits from preventing oil-filled equipment failures that release thousands of gallons of dielectric fluid. Early detection and repair of partial discharge activity in transformers and oil-filled cables prevents environmental contamination incidents.

Extended equipment lifespan results from addressing insulation degradation before irreversible damage occurs. Targeted repairs guided by partial discharge location information restore equipment to acceptable condition at a fraction of replacement expense.

Optimized maintenance scheduling based on actual condition rather than conservative time-based intervals reduces unnecessary interventions while preventing failure-related emergencies. Condition-based approaches balance reliability requirements against maintenance resource allocation.

Reduced downtime through planned maintenance during scheduled outages eliminates expensive emergency repairs and unplanned production interruptions. The economic impact of avoiding unscheduled outages far exceeds testing investment across most industrial and utility applications.

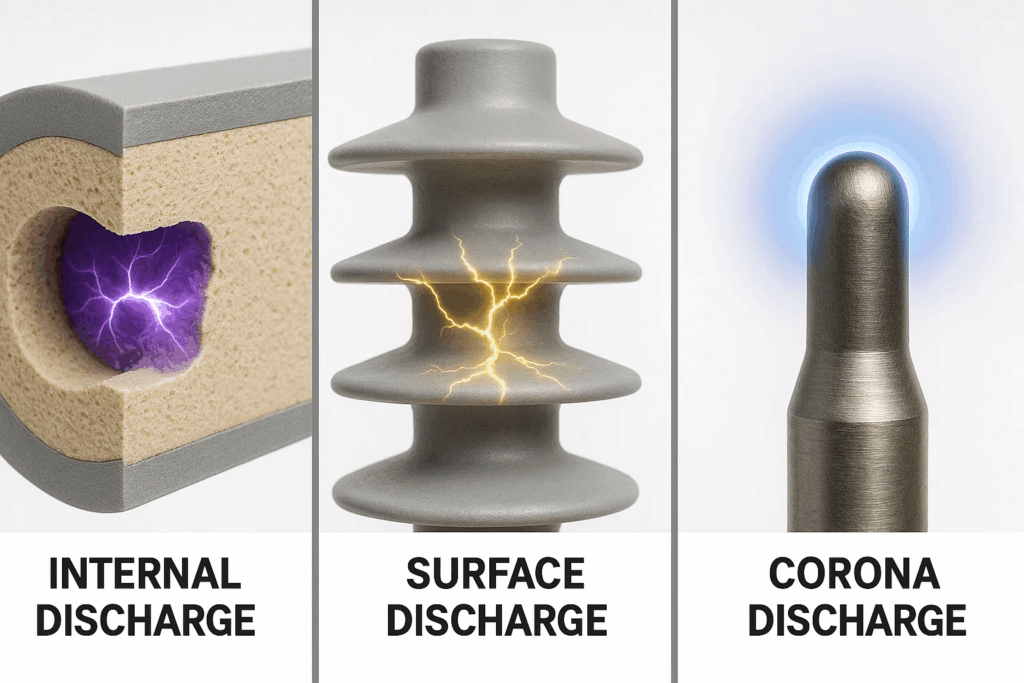

Internal partial discharge occurs within voids, cracks, or delaminations inside solid insulation materials. These trapped cavities contain gas at lower dielectric strength than surrounding solid insulation, breaking down at voltage levels the solid material withstands.

Void discharge characteristics produce distinctive patterns in phase-resolved partial discharge analysis. Discharge inception and extinction voltages relate to void geometry and gas composition, creating fingerprints identifying specific defect types during diagnostic interpretation.

Cable insulation voids commonly develop from manufacturing imperfections, installation damage, or aging processes. Extruded insulation materials contract during cooling creating microscopic voids, while aged cross-linked polyethylene develops treeing channels propagating through insulation.

Solid insulation delamination in generator stator bars creates gas-filled spaces between insulation layers. Thermal cycling and mechanical vibration cause debonding that progresses with operational time, eventually creating discharge sites requiring rewinding.

Surface partial discharge develops along insulation boundaries where contamination, moisture, or tracking creates conductive paths. The discharge propagates across the insulation surface rather than penetrating through bulk material.

Contamination effects dramatically reduce surface flashover voltage. Conductive deposits from environmental exposure or internal degradation products create preferential discharge paths. Moisture absorption further reduces surface resistance amplifying discharge severity.

Tracking formation results from sustained surface discharge chemically degrading insulation materials. Carbonized paths gradually extend across surfaces eventually creating complete breakdown when tracks connect electrodes. Outdoor insulators and cable terminations commonly exhibit tracking degradation.

Interface discharge occurs at boundaries between different insulation materials exhibiting mismatched dielectric constants. Electric field concentrations at these interfaces initiate discharge activity that progressively damages the interface region.

Corona represents partial discharge in gas surrounding high-voltage conductors when electric field intensity exceeds air ionization threshold. This external discharge differs from internal and surface types but produces similar progressive degradation effects.

Air terminal discharge from sharp points, conductor surface irregularities, and insufficient spacing creates audible noise, radio interference, and progressive conductor corrosion. Transmission line hardware optimization minimizes corona through proper conductor sizing and fitting design.

End-winding corona in rotating machines occurs where winding emerges from stator slots experiencing air exposure under high voltage stress. Proper stress grading and semi-conductive coating application controls end-winding corona in modern machines.

Gas-insulated equipment experiences corona within SF6 or alternative gases when contamination particles, surface roughness, or assembly defects create field enhancements. The higher dielectric strength of compressed gases requires greater field intensities for discharge inception compared to atmospheric air.

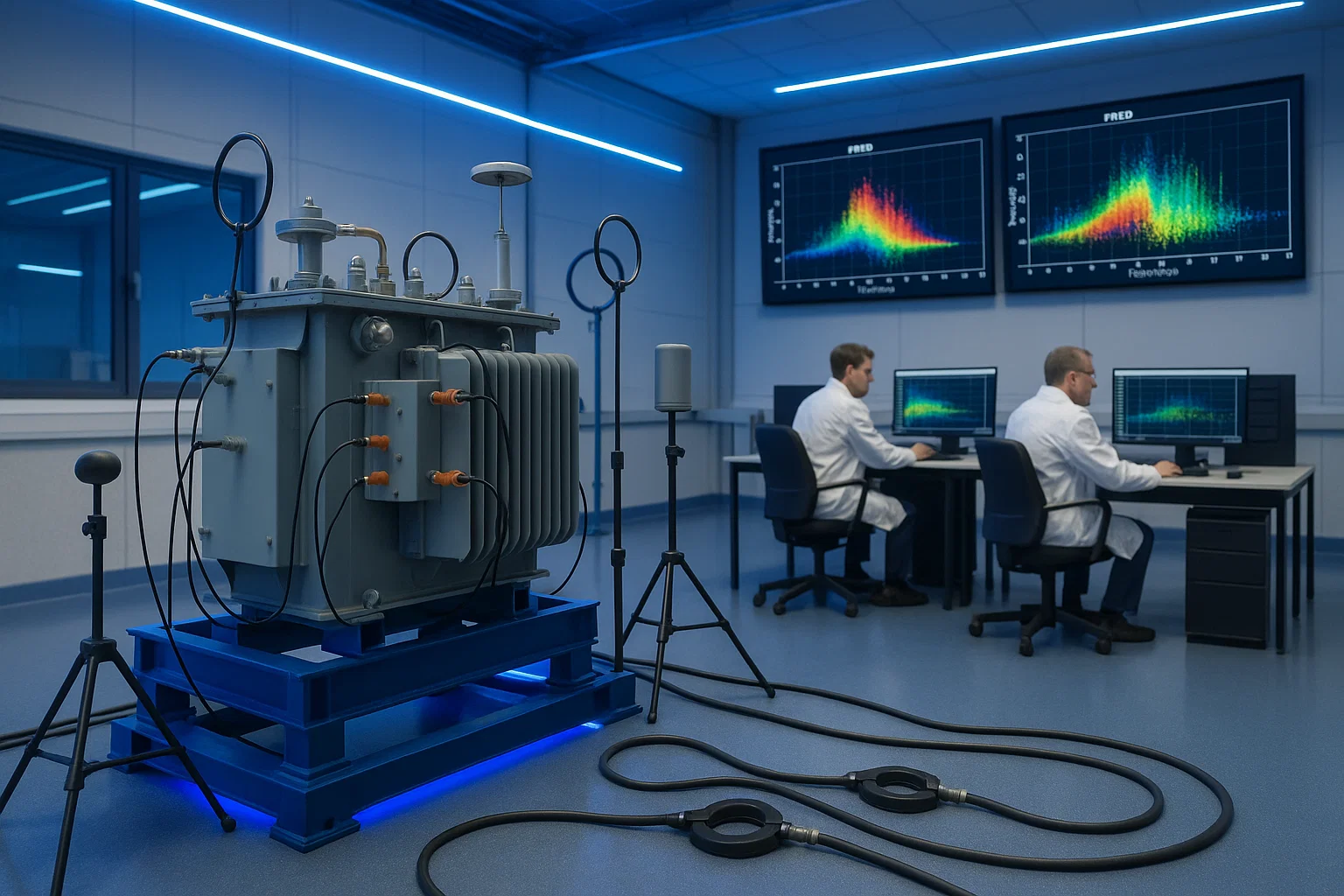

Electrical partial discharge measurement represents the most established and standardized approach, directly detecting discharge currents flowing through test circuits. International standards including IEC 60270 define measurement circuits, calibration procedures, and reporting requirements ensuring reproducible results.

Conventional testing according to IEC 60270 measures apparent charge in picocoulombs using calibrated detection circuits. Test equipment captures high-frequency current pulses generated by discharge events, converting them to voltage signals for analysis. Understanding the relationship between surge testing and hipot testing helps appreciate how partial discharge testing complements these established techniques.

Wide-band measurement captures discharge signals across broad frequency ranges providing detailed pulse shape information. Analysis of rise time, duration, and frequency content enables advanced pattern recognition distinguishing between discharge types and external interference.

Narrowband tuned detection filters measurement signals to specific frequency ranges minimizing interference from external electromagnetic noise. This selective approach achieves high sensitivity in electrically noisy environments where broadband detection suffers from poor signal-to-noise ratios.

Acoustic partial discharge detection monitors ultrasonic emissions generated by discharge events, providing sensitivity to discharges not readily detected electrically. The acoustic approach excels at localizing discharge sites within large equipment like transformers.

Ultrasonic sensors mounted on equipment surfaces detect mechanical vibrations propagating from discharge sites. Piezoelectric transducers convert acoustic waves to electrical signals for analysis, with frequency response optimized for partial discharge signature ranges.

Time-of-flight localization determines discharge position by analyzing signal arrival times at multiple sensors. Sophisticated algorithms account for acoustic propagation characteristics through different materials and geometries calculating three-dimensional source locations.

Online monitoring capability enables continuous acoustic surveillance during normal operation. Permanently installed sensor arrays provide trending data revealing discharge activity changes correlating with operational parameters and environmental conditions.

UHF partial discharge detection measures electromagnetic radiation in the 300 MHz to 3 GHz frequency range generated by rapid current changes during discharge events. This method offers exceptional noise rejection and sensitivity particularly in gas-insulated equipment.

Antenna coupling through inspection windows, drain valves, or dedicated sensors captures UHF emissions from discharge sites. The metallic enclosures of transformers and gas-insulated switchgear act as waveguides channeling signals to detector locations.

Pattern recognition algorithms analyze UHF signal characteristics distinguishing partial discharge from switching transients, corona, and external interference. Machine learning approaches trained on extensive datasets achieve high classification accuracy automating defect identification.

Integration with conventional testing combines UHF sensitivity with IEC 60270 quantification providing comprehensive characterization. UHF detection identifies discharge presence and approximate location while conventional measurement quantifies severity against acceptance criteria.

HFCT sensors provide non-invasive online partial discharge detection by monitoring high-frequency currents in equipment ground connections. This approach enables testing without service interruption or direct connection to high-voltage circuits.

Clamp-on installation around grounding conductors couples capacitively to discharge currents flowing through ground paths. The non-invasive nature allows temporary or permanent installation without modifying existing equipment or affecting operation.

Directional sensitivity distinguishes discharge sources within monitored equipment from external interference. Advanced sensors incorporate directional coupling providing information about discharge location relative to sensor position.

Combined sensor arrays using multiple HFCTs at different positions enable source localization and improved signal-to-noise ratios. Simultaneous multi-channel acquisition supports time-of-arrival analysis and coherence-based interference rejection.

IEC 60270 establishes the foundational standard for partial discharge measurement defining test circuits, calibration methods, measurement procedures, and result interpretation. This standard ensures measurement reproducibility and comparability across different testing laboratories and equipment manufacturers.

IEC 60034-27 specifically addresses partial discharge measurements on rotating electrical machines providing guidance for both off-line and on-line testing approaches. The standard recognizes unique challenges of testing motors and generators including coupling methods and interference mitigation.

IEEE 400 series standards cover cable system testing including partial discharge measurements during commissioning and maintenance activities. These standards address field testing challenges and provide acceptance criteria for various cable types and voltage classes.

IEC 61934 extends partial discharge measurement standards to equipment experiencing repetitive voltage impulses and short rise time stresses. This standard addresses modern power electronics applications where conventional AC partial discharge testing proves insufficient.

Transformer testing standards including IEC 60076 specify partial discharge limits for factory acceptance testing and type testing. Requirements vary by transformer construction, voltage class, and application with tighter limits for critical or large power transformers.

Generator and motor standards establish partial discharge acceptance criteria considering winding configuration, insulation system type, and voltage rating. Form-wound windings in larger machines face stricter requirements than random-wound constructions in smaller equipment.

Cable acceptance testing follows manufacturer specifications and utility standards defining maximum permissible partial discharge levels after installation. Testing protocols address challenges of field testing including interference rejection and sensitivity verification. Understanding high voltage testing fundamentals provides context for partial discharge testing within broader electrical safety protocols.

Understanding compliance requirements for digital surge testing equipment helps appreciate how different testing approaches complement each other in comprehensive quality assurance programs.

Charge injection calibration establishes measurement system sensitivity by injecting known charge quantities into test circuits. Calibrators generate precise pulses simulating partial discharge enabling apparent charge determination traceable to international standards.

Sensitivity verification confirms detection system capability to measure specified minimum discharge magnitudes. Background noise levels, filter settings, and coupling efficiency all influence achievable sensitivity requiring systematic verification.

Periodic recalibration maintains measurement accuracy over time accounting for component aging and environmental effects. Quality management systems specify calibration intervals based on equipment criticality and manufacturer recommendations.

Power and distribution transformers represent primary partial discharge testing applications given their critical infrastructure role and failure consequences. Testing occurs during factory acceptance, site commissioning, and periodic condition assessment.

Factory acceptance testing verifies new transformers meet partial discharge specifications before shipment. Controlled testing environments enable sensitive measurements establishing baseline performance documentation.

Field commissioning tests confirm proper installation and absence of transport damage or installation-induced defects. Testing protocols adapt to site conditions including interference management and limited access to ideal measurement points.

Condition assessment monitoring tracks partial discharge activity trends identifying degradation requiring intervention. Combining PD testing with dissolved gas analysis and other diagnostics provides comprehensive transformer health evaluation.

Rotating machines experience unique partial discharge challenges from slot discharge, end-winding corona, and turn-to-turn insulation stress. Both off-line and on-line testing approaches support condition-based maintenance programs.

Stator winding testing focuses on detecting turn insulation deterioration, slot discharge activity, and end-winding problems. Proper testing of three-phase motor windings incorporates partial discharge assessment alongside resistance and surge testing.

Generator condition monitoring employs permanently installed sensors providing continuous partial discharge surveillance. Real-time monitoring during operation reveals discharge characteristics under actual thermal and mechanical stress conditions.

Predictive maintenance scheduling bases generator rewinding decisions on partial discharge trends combined with other condition indicators. Data-driven approaches optimize maintenance timing balancing reliability against intervention expense.

Underground and submarine cable systems benefit substantially from partial discharge testing identifying joint, termination, and insulation defects before service failures occur.

Cable commissioning verifies installation quality detecting damage from pulling tension, bending radius violations, or contamination during installation. Establishing baseline measurements enables future comparison assessing degradation rates.

Periodic condition assessment tracks cable system aging identifying sections requiring rehabilitation or replacement. Geographic information systems integrate partial discharge data with asset records supporting strategic investment planning.

After repair verification confirms restoration quality following splice replacement or termination refurbishment. Testing validates work quality before returning equipment to service preventing premature repeat failures.

Gas-insulated and air-insulated switchgear both experience partial discharge from contact deterioration, insulator contamination, and manufacturing defects.

Factory testing ensures new switchgear meets partial discharge specifications before delivery. Sensitive controlled environment measurements establish quality benchmarks.

Commissioning verification confirms proper installation without introducing contamination or assembly defects. UHF detection methods excel in gas-insulated switchgear providing high sensitivity to internal discharge sources.

In-service monitoring detects developing problems before catastrophic failure. Switchgear reliability improvements from partial discharge monitoring significantly reduce unexpected outages and associated production losses.

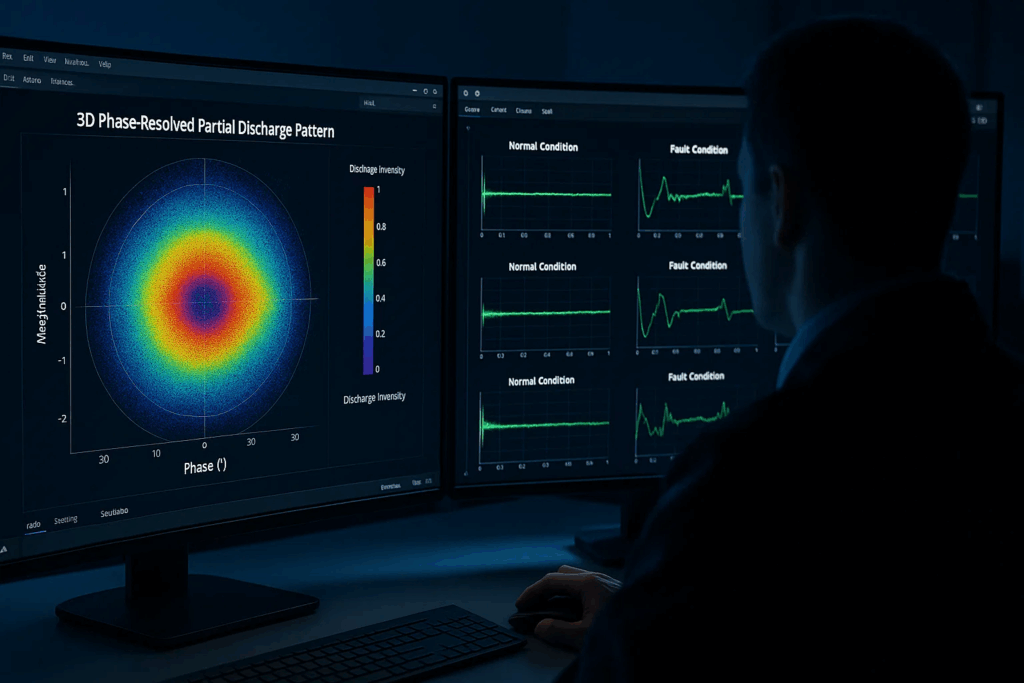

PRPD analysis correlates discharge occurrence with power frequency phase angle revealing characteristic patterns identifying specific defect types. Different discharge mechanisms produce distinctive fingerprints in phase-amplitude-frequency distributions.

Internal void discharge typically appears symmetrically distributed around AC voltage peaks with inception occurring as voltage rises and extinction as voltage declines. The pattern reflects charge accumulation and dissipation dynamics within gas-filled voids.

Surface tracking discharge shows asymmetric patterns often concentrated in positive or negative half-cycles depending on surface conditions and contamination characteristics. Progressive tracking development alters patterns as degradation advances.

Corona discharge produces continuous activity throughout voltage cycles with amplitude increasing as voltage magnitude rises. External corona patterns differ distinctly from internal and surface discharge enabling discrimination.

Examining individual discharge pulse characteristics and sequences provides additional diagnostic information beyond phase-resolved patterns.

Pulse shape analysis extracts information from rise time, duration, and frequency content characterizing discharge physics and propagation paths. Fast rise times indicate nearby discharge sources while slower pulses suggest greater distance or filtering.

Pulse repetition statistics reveal discharge mechanisms through inter-pulse timing distributions. Void discharges show statistical clustering reflecting charge accumulation dynamics while surface discharges exhibit different temporal characteristics.

Correlation analysis between multiple detection channels enables source localization and interference rejection. Simultaneous measurements at different positions combined with time-of-arrival analysis pinpoints discharge locations within complex equipment.

Longitudinal data analysis tracking partial discharge evolution reveals degradation rates and intervention timing.

Baseline comparison against initial commissioning measurements quantifies deterioration from original condition. Establishing acceptance criteria based on change magnitude rather than absolute values accounts for manufacturing variations.

Operational correlation identifies relationships between discharge activity and loading, temperature, or environmental conditions. Understanding these dependencies distinguishes normal operational variations from progressive degradation.

Predictive analytics apply statistical modeling and machine learning to discharge trends forecasting remaining useful life. These approaches support optimization of maintenance timing balancing reliability and resource utilization.

Off-line partial discharge testing during scheduled maintenance outages provides comprehensive assessment under controlled conditions.

Testing frequency determination balances detection capability against interruption frequency. Critical equipment may justify annual testing while less critical assets test on longer cycles guided by manufacturer recommendations and historical data.

Test preparation requirements include cleaning, drying, and interference elimination optimizing measurement sensitivity. Proper preparation significantly improves detection capability particularly for aged equipment exhibiting surface contamination.

Documentation standards ensure consistent data collection enabling meaningful historical comparison. Standardized test reports, measurement parameters, and result interpretation facilitate trending analysis and maintenance decisions.

Permanently installed monitoring systems provide continuous partial discharge surveillance during normal operation revealing characteristics invisible during off-line testing.

Sensor installation design considers access, electromagnetic environment, and coverage requirements. Optimized sensor placement balances detection sensitivity against practical installation constraints.

Data management systems handle continuous acquisition generating massive datasets requiring intelligent processing. Automated algorithms filter routine operational variations highlighting significant changes requiring attention.

Integration with asset management connects partial discharge data with maintenance management systems, SCADA networks, and condition-based maintenance programs. Unified platforms combine multiple diagnostic inputs supporting holistic equipment health assessment.

Combining periodic off-line testing with limited on-line monitoring balances comprehensive assessment against continuous surveillance.

Critical equipment monitoring concentrates continuous monitoring resources on highest-value or highest-risk assets while applying periodic testing to remaining population. Risk-based strategies optimize resource allocation across asset portfolios.

Event-triggered testing supplements scheduled testing with diagnostic measurements following unusual operational events. Fault conditions, overload events, or abnormal monitoring indications trigger detailed assessment determining impact.

Progressive implementation starts with pilot installations demonstrating value before enterprise-wide deployment. Learning from initial installations guides subsequent optimization and scaling decisions.

Understanding troubleshooting approaches for electrical testing helps maintain testing system effectiveness throughout implementation.

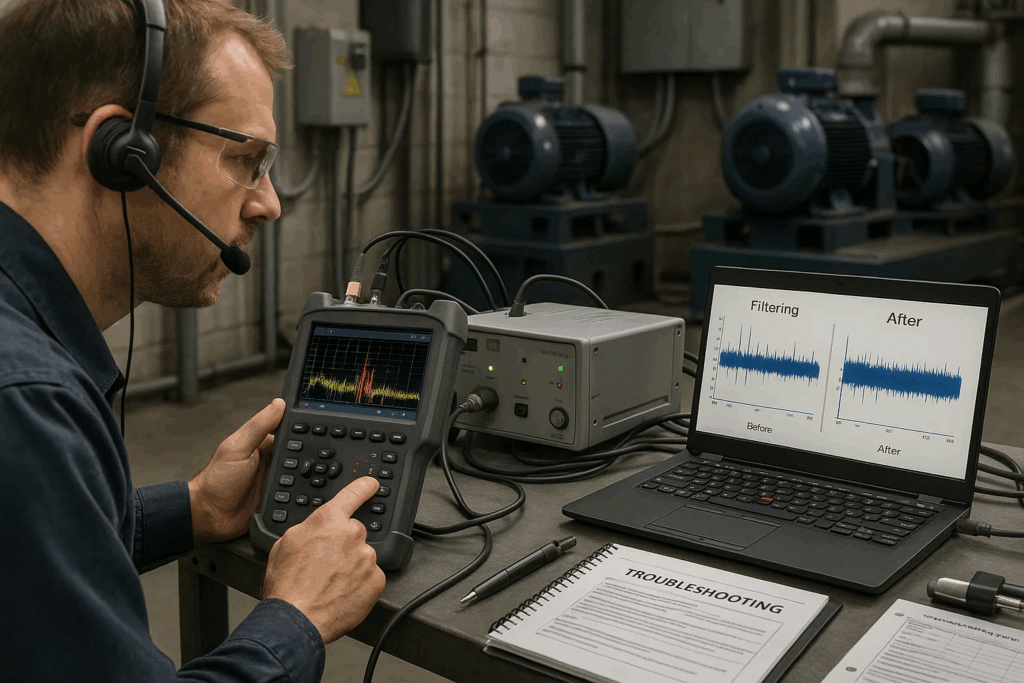

External electromagnetic sources complicate partial discharge measurement creating false indications and masking genuine discharge signals.

Shielding effectiveness reduces external field coupling through proper grounding, cable routing, and sensor shielding. Test circuit design incorporating guard shields and balanced configurations rejects common-mode interference.

Frequency selection chooses measurement bands minimizing interference while maximizing discharge signal strength. Site surveys identify occupied frequency ranges guiding band selection for optimal signal-to-noise ratios.

Digital filtering employs sophisticated signal processing removing interference while preserving discharge signatures. Adaptive filters learn interference characteristics automatically adjusting rejection parameters.

Achieving adequate sensitivity requires addressing coupling efficiency, background noise, and propagation losses.

Coupling optimization maximizes discharge signal capture through proper sensor selection and positioning. Capacitive coupling, inductive coupling, and acoustic coupling each offer advantages depending on equipment configuration and access.

Noise reduction addresses both external electromagnetic interference and internal electronic noise. Low-noise amplifiers, proper grounding, and environmental control improve detection thresholds.

Signal enhancement through advanced processing techniques extracts weak discharge signals from noise. Correlation techniques, wavelet analysis, and machine learning approaches identify subtle patterns invisible to conventional processing.

Partial discharge pattern interpretation requires expertise combining understanding of discharge physics, equipment construction, and operational history.

Expert system development captures diagnostic knowledge in automated decision support tools. Rule-based systems and machine learning models assist less experienced personnel while maintaining consistency.

Training programs develop interpreter competence through classroom instruction, hands-on practice, and mentored experience. Certification programs establish competency standards supporting quality assurance.

Specialist consultation addresses complex cases exceeding internal expertise. Access to experienced diagnosticians through service contracts or consulting relationships provides troubleshooting support.

Machine learning transforms partial discharge diagnostics through automated pattern recognition and predictive analytics.

Deep learning classification automatically categorizes discharge patterns achieving accuracy approaching or exceeding human experts. Convolutional neural networks trained on extensive databases recognize subtle features in PRPD patterns.

Anomaly detection algorithms identify unusual discharge characteristics warranting investigation without requiring training on specific defect types. These unsupervised approaches discover novel failure modes missed by traditional classification.

Predictive modeling forecasts equipment condition trajectory estimating remaining life from current measurements and degradation trends. Integration with maintenance planning systems optimizes intervention timing balancing reliability and resource utilization.

Wireless sensor networks and internet connectivity enable scalable monitoring deployments and remote diagnostics.

Battery-powered sensors eliminate installation cabling requirements enabling economical retrofits on existing equipment. Energy harvesting from equipment magnetic fields powers perpetual operation.

Cloud analytics platforms aggregate data from distributed monitoring systems providing fleet-wide visibility and comparative analysis. Centralized processing applies advanced algorithms impractical for local implementations.

Remote diagnostics enable expert analysis from central facilities supporting field operations lacking specialized expertise. Secure connectivity provides real-time collaboration during troubleshooting and interpretation.

Combining partial discharge with complementary diagnostics provides comprehensive condition assessment.

Dissolved gas analysis correlation relates partial discharge patterns to specific gas generation rates and ratios. Combined interpretation improves defect characterization beyond either technique alone.

Thermal imaging integration associates discharge locations with temperature anomalies validating source identification. Simultaneous measurement reveals relationships between electrical and thermal phenomena.

Vibration analysis fusion connects partial discharge with mechanical signatures detecting combined electrical-mechanical degradation modes. Multi-physics approaches address complex failure mechanisms individual diagnostics miss.

Modern surge testing approaches increasingly incorporate partial discharge capability creating comprehensive diagnostic platforms.

Generating stations employ partial discharge monitoring protecting critical assets supporting power production.

Generator stator monitoring prevents unexpected failures threatening grid stability and production capacity. Permanently installed systems provide continuous surveillance during operation when thermal and mechanical stresses peak.

Step-up transformer protection safeguards expensive assets connecting generation to transmission networks. Combined partial discharge and dissolved gas monitoring provides early warning of developing problems.

Auxiliary equipment surveillance extends monitoring to critical balance-of-plant components including station service transformers and medium-voltage motors. Comprehensive monitoring maximizes plant availability.

Utility networks apply partial discharge testing maintaining grid reliability and preventing service interruptions.

Substation transformer monitoring detects developing problems before failures cascade through networks. Strategic monitoring deployment focuses on critical nodes and aged assets.

Cable system management guides rehabilitation and replacement decisions optimizing infrastructure investment. Partial discharge trending combined with circuit importance prioritizes intervention sequencing.

Mobile testing services provide periodic assessment of non-monitored equipment. Testing vans equipped with comprehensive diagnostic capabilities efficiently survey large equipment populations.

Manufacturing facilities and process plants utilize partial discharge testing minimizing production disruptions.

Critical motor protection prevents unexpected failures of process-critical drives. Monitoring systems coordinate with maintenance management scheduling interventions during planned outages.

Transformer fleet management optimizes maintenance across multiple units supporting production facilities. Condition-based approaches reduce maintenance costs while improving reliability.

Quality assurance programs verify new equipment meets specifications before commissioning. Factory and site acceptance testing confirms proper manufacturing and installation.

Partial discharge testing detects early-stage insulation degradation by measuring small continuous electrical breakdowns in picocoulombs during normal voltage operation. Surge testing applies high-voltage impulses to identify turn-to-turn winding faults through waveform comparison. PD testing is more sensitive for incipient failures, while surge testing excels at detecting severe manufacturing defects. Both methods complement each other in comprehensive diagnostics.

Yes, online partial discharge testing uses non-invasive sensors like HFCT clamps, UHF antennas, and acoustic transducers on energized equipment. Online testing captures PD activity under actual operating conditions with full thermal and electrical stress. However, electromagnetic interference requires advanced filtering to distinguish genuine PD signals from environmental noise.

Acceptance criteria vary by equipment type and voltage class. Power transformers typically allow 100-500 picocoulombs per IEC 60076, while motors range from 50-1000 pC under IEC 60034-27. New equipment has stricter limits than in-service units. Trending over time is often more critical than absolute values—increasing discharge indicates deteriorating condition.

Testing frequency depends on equipment criticality, age, and operating environment. Critical equipment warrants annual testing, while less critical assets test every 3-5 years. Newly installed equipment should be tested at commissioning to establish baselines. Continuous online monitoring provides real-time surveillance for highest-value assets, while periodic offline testing suits general populations.

Partial discharge results from manufacturing defects (voids, contaminants), installation damage (moisture ingress, mechanical stress), aging degradation (thermal cycling, chemical breakdown), and operational stress (voltage surges, overloading). Common sources include air voids in solid insulation, surface contamination on bushings, inadequate stress control in cable terminations, and loose connections in switchgear. Environmental factors like humidity and temperature accelerate PD development.

Partial discharge testing represents the most sensitive early warning diagnostic available for electrical insulation systems. The technology continues evolving through digital signal processing, artificial intelligence, and wireless communications expanding capability while reducing implementation barriers.

Successful programs integrate partial discharge testing within comprehensive condition-based maintenance strategies combining multiple diagnostic techniques. This multi-parameter approach provides robust condition assessment supporting optimized maintenance decisions balancing reliability requirements against resource constraints.

Organizations embracing partial discharge testing gain competitive advantages through improved reliability, extended equipment life, and optimized maintenance spending. The initial investment in testing capability and expertise development delivers sustained returns through prevented failures and improved operational performance.

As electrical systems grow more critical supporting modern infrastructure, partial discharge testing becomes essential rather than optional. Forward-thinking asset managers recognize this reality implementing programs positioning their organizations for reliable sustainable operations.

Ready to implement partial discharge testing in your facility? Contact our diagnostic specialists to discuss customized monitoring solutions and testing programs aligned with your equipment population and operational requirements.