Railway maintenance downtime costs operators thousands of dollars per hour, with traditional heating methods often causing thermal damage to precision components and extending repair windows unnecessarily. The consequences? Delayed schedules, compromised safety standards, and escalating operational expenses that strain budgets and reduce fleet availability. Advanced induction heating solutions eliminate these challenges by delivering precise, rapid, and safe thermal processing for critical railway components—transforming maintenance operations from costly liabilities into streamlined efficiency gains.

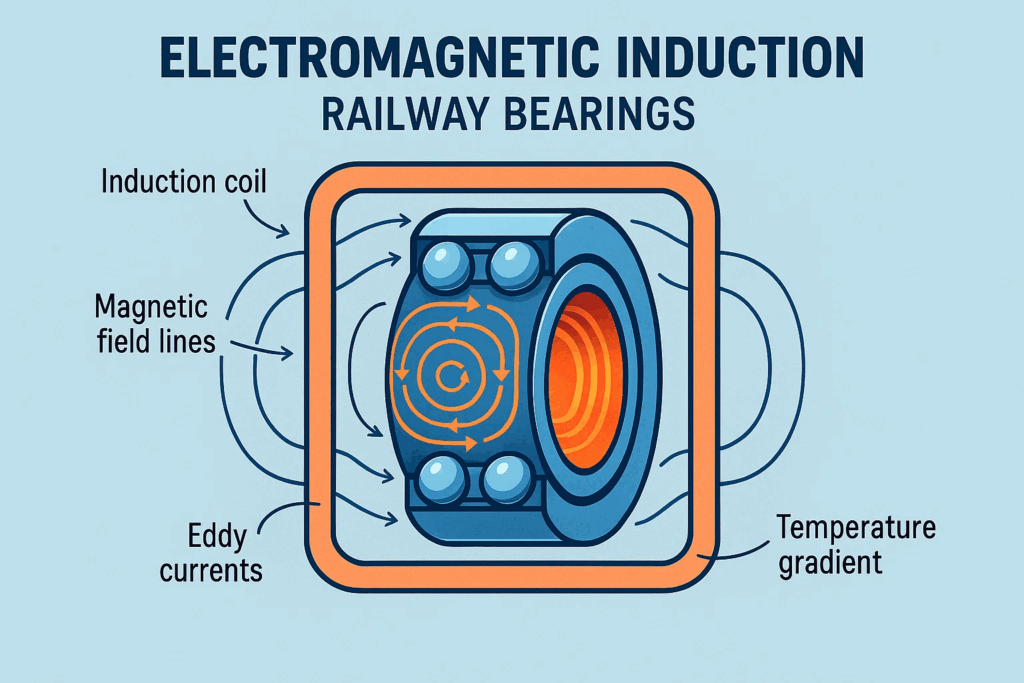

Induction heating harnesses electromagnetic energy to generate heat directly within conductive materials, offering unparalleled precision for railway component installation and maintenance. Unlike flame torches or resistance heaters that apply external heat inconsistently, electromagnetic induction creates controlled thermal expansion without surface scorching or metallurgical degradation.

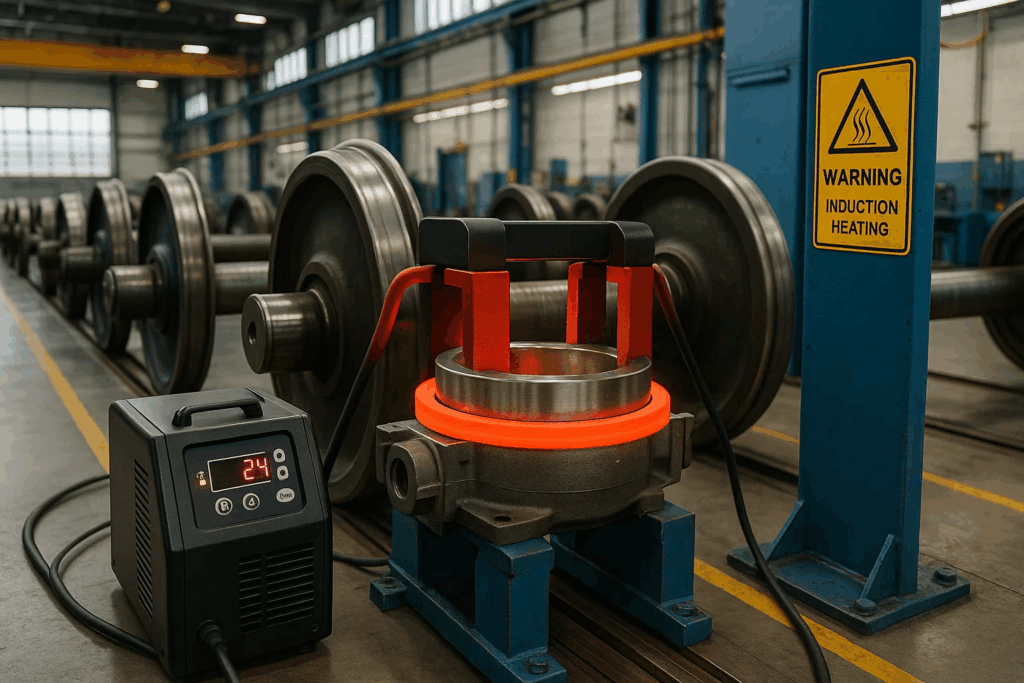

The railway industry demands heating solutions that accommodate massive components—from 500-pound wheel bearings to multi-ton rotor assemblies—while maintaining dimensional tolerances measured in microns. Modern induction heating systems deliver this precision through programmable temperature profiles, ensuring uniform heat distribution across complex geometries.

Railway maintenance facilities experience immediate operational benefits when transitioning to induction-based thermal processing:

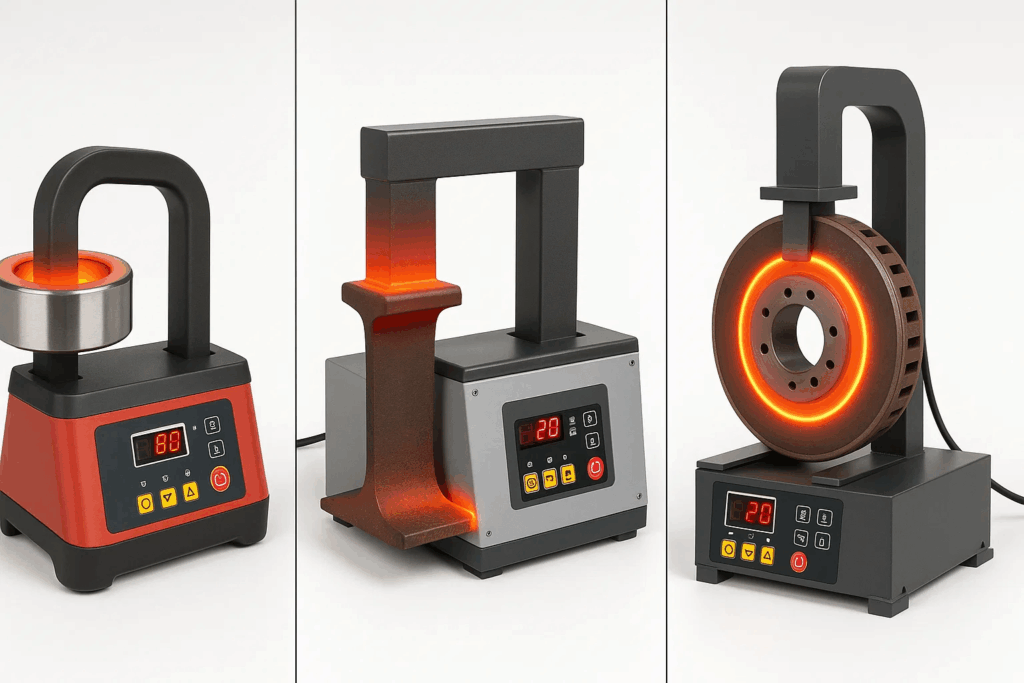

Selecting the optimal induction heating solution requires matching system capabilities to specific railway maintenance requirements. Three primary categories dominate the railway sector, each engineered for distinct operational scenarios.

Compact, wheeled units designed for trackside repairs and remote depot operations offer mobility without sacrificing heating capacity. These systems typically accommodate bearings from 20mm to 500mm inner diameter, with power outputs ranging from 3.6kW to 24kW.

Ideal Applications:

Modern portable units incorporate advanced safety features, including automatic demagnetization cycles and overheating protection that preserve bearing integrity during field installations.

Heavy-duty bearing induction heaters anchored in centralized maintenance facilities provide maximum heating capacity for locomotive and freight car overhauls. These powerhouses handle components weighing up to 2,000 pounds, with precise temperature control spanning 50°C to 250°C.

Workshop-grade systems feature programmable memory functions storing heating profiles for hundreds of component types, enabling technicians to recall optimal parameters instantly. This standardization eliminates guesswork and reduces training requirements for new maintenance personnel.

Specialized solutions for heating massive assemblies—traction motor rotors, axle-mounted gears, and structural couplings—represent the pinnacle of railway induction technology. These systems deliver 50kW to 200kW output, achieving uniform heating across components measuring several meters in diameter.

Induction heating for large rotors requires sophisticated coil designs that accommodate irregular geometries while maintaining thermal uniformity. Advanced monitoring systems track temperature gradients in real-time, automatically adjusting power delivery to prevent localized overheating.

Railway operations encompass diverse thermal processing requirements, each demanding specific induction heating characteristics to ensure successful outcomes and long-term reliability.

Wheel bearings, axle box bearings, and traction motor bearings require controlled thermal expansion for proper fitment onto shafts and housings. Induction heating delivers uniform temperature distribution, preventing the bearing race distortion that plagues flame heating methods.

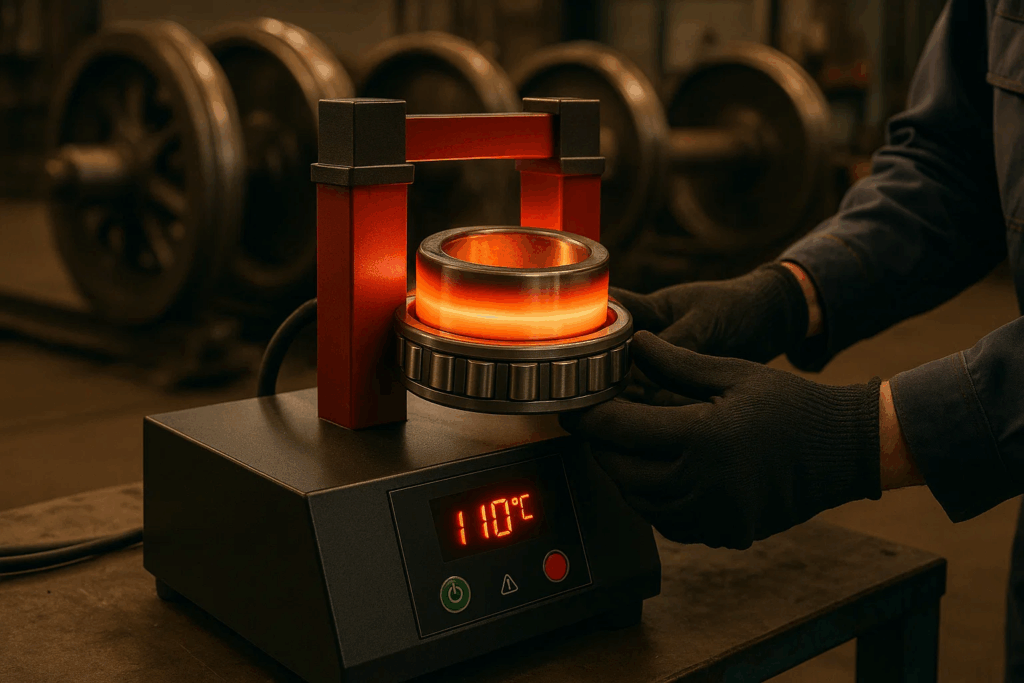

The shrink fitting process achieves interference fits ranging from 0.025mm to 0.150mm, ensuring optimal load distribution and vibration resistance throughout service life. Automated temperature monitoring prevents overheating beyond bearing steel tempering thresholds, typically 120°C for precision bearings.

Railway bogies incorporate numerous bronze bushings and elastomeric couplings requiring thermal installation techniques. Heating bushings safely demands precise control to prevent elastomer degradation or bronze microstructure changes that compromise wear resistance.

Induction systems programmed with component-specific thermal profiles eliminate installation damage, extending service intervals and reducing unplanned maintenance events. This precision proves particularly valuable for high-speed rail applications where component tolerances directly impact ride quality and safety margins.

Locomotive traction gears and wheel-mounted brake discs utilize interference fits achieved through controlled thermal expansion. Traditional heating methods risk warping thin-section components, creating runout issues that manifest as vibration and accelerated wear.

Modern induction solutions incorporate rotation mechanisms that ensure circumferential heating uniformity, maintaining dimensional accuracy within 0.05mm across diameters exceeding one meter. This precision proves critical for high-speed rail operations where wheel balance directly affects passenger comfort and track wear rates.

Electric locomotive traction motors contain pressed-fit components requiring periodic disassembly for bearing replacement and winding refurbishment. Induction heating enables controlled removal of interference-fit rotors, armatures, and bearing housings without mechanical force that damages precision surfaces.

Choosing the right induction heating solution demands careful evaluation of technical specifications, operational requirements, and long-term maintenance considerations that impact total ownership costs.

Railway components span enormous mass ranges, requiring induction systems with appropriate power reserves. Undersized equipment extends heating cycles unnecessarily, while oversized units waste energy and increase capital costs.

Power Selection Guidelines:

Consider peak demand scenarios when sizing equipment—occasional large component heating may justify rental solutions rather than permanent capacity investments.

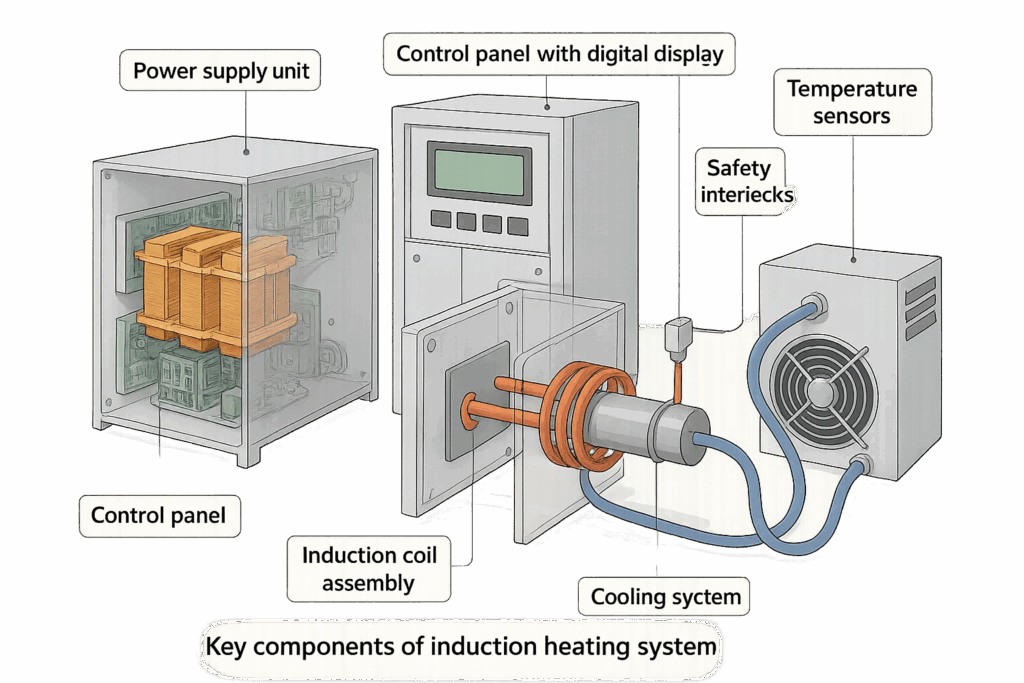

Bearing steel metallurgy dictates strict temperature limits, typically 120°C maximum to prevent tempering that reduces hardness and load capacity. Premium induction systems offer ±2°C accuracy through closed-loop temperature monitoring and automated power modulation.

Advanced units integrate infrared pyrometers and thermocouples that continuously validate heating uniformity, triggering alarms before components exceed damage thresholds. This safeguarding proves essential for maintaining bearing warranty coverage and preventing costly premature failures.

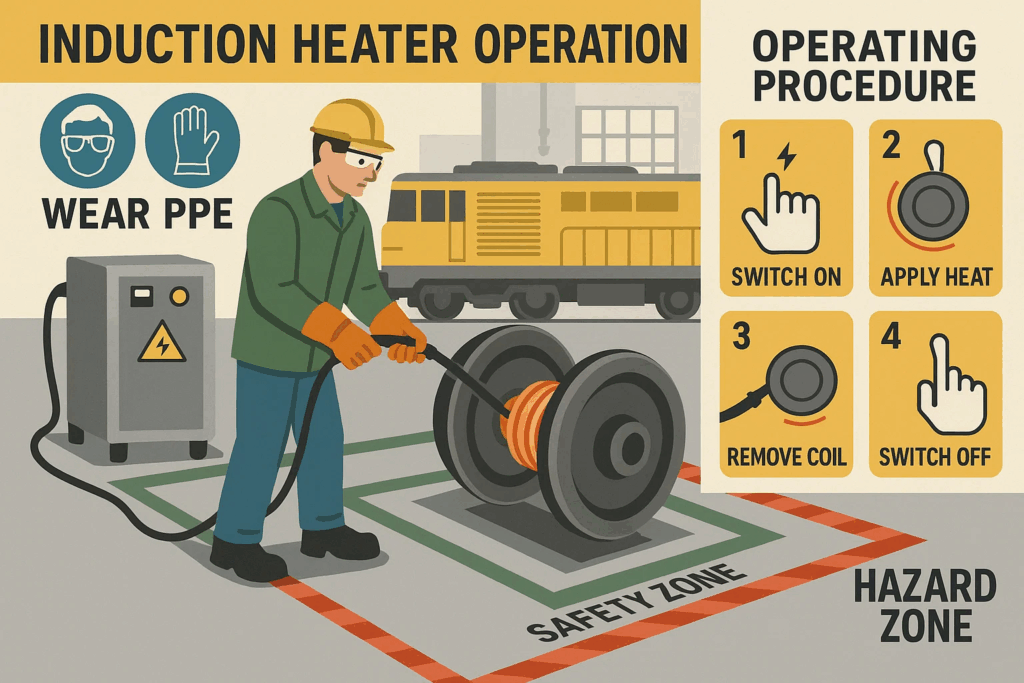

Railway maintenance facilities must adhere to stringent safety regulations governing electromagnetic emissions, electrical safety, and operator protection. Quality induction heating equipment carries certifications including CE marking, UL/CSA approval, and ISO compliance documentation.

Essential safety features for induction heaters include automatic demagnetization cycles preventing residual magnetism that attracts metal particles into bearings, emergency shutdown systems, and ground fault protection that isolates equipment during electrical anomalies.

Railway workshop environments subject equipment to harsh conditions—metal dust, hydraulic oil contamination, and continuous operation across extended shifts. Industrial-grade induction heaters feature sealed electronics enclosures, heavy-duty power supplies, and replaceable heating coils designed for 10,000+ heating cycles.

Evaluate manufacturer support infrastructure, including spare parts availability, field service response times, and calibration services. Equipment downtime directly translates to maintenance bottlenecks that cascade through entire fleet schedules.

Successful integration of induction heating technology requires systematic planning, comprehensive operator training, and established protocols that maximize equipment effectiveness while maintaining safety standards.

Even intuitive induction heating systems demand trained operators who understand electromagnetic principles, bearing metallurgy, and proper installation techniques. Comprehensive training programs should encompass:

Establish refresher training intervals aligned with equipment manufacturer recommendations, typically annually or following extended operational breaks.

Induction heating equipment reliability directly influences overall maintenance facility productivity. Institute scheduled inspection routines covering:

Document all maintenance activities in equipment logbooks, establishing trending data that identifies degradation patterns before failures occur.

Implement standardized heating records that capture critical parameters for each component processed through induction equipment. Essential documentation includes:

This documentation creates traceability chains that support warranty claims, failure investigations, and continuous improvement initiatives targeting maintenance quality enhancement.

.

Understanding the comparative advantages of induction technology against legacy heating approaches clarifies the business case for equipment investment and operational transformation.

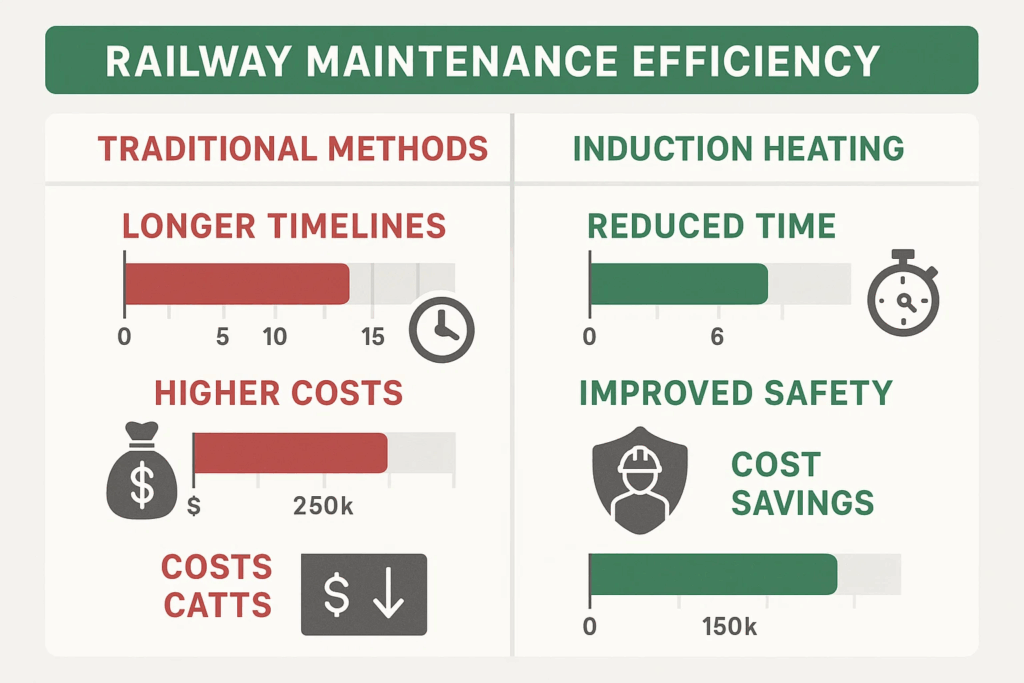

Oxy-acetylene torches and propane burners dominated railway maintenance for decades, despite inherent limitations that compromise safety and quality outcomes. Open flame methods create fire hazards in oil-contaminated environments, require expensive ventilation systems, and produce inconsistent heating patterns that damage precision components.

Temperature control with flame heating relies entirely on operator skill and experience, creating quality variations between technicians and shifts. The absence of automated monitoring prevents detection of overheating until visible discoloration indicates metallurgical damage has occurred.

Electric band heaters and hot plates offer improved safety versus open flames but suffer from extended heating cycles and poor thermal efficiency. These systems heat bearing outer races first, requiring prolonged cycles before inner race temperatures reach installation thresholds—sometimes exceeding 4-6 hours for large components.

The prolonged exposure to elevated temperatures increases oxidation, potentially introducing surface contamination that compromises bearing life. Additionally, resistance heaters lack portability, restricting their utility to fixed workshop locations rather than trackside repair scenarios.

| Factor | Induction Heating | Flame Heating | Resistance Heating |

|---|---|---|---|

| Heating Speed | 15-45 minutes | 30-90 minutes | 2-6 hours |

| Temperature Accuracy | ±2°C | ±15°C | ±8°C |

| Energy Efficiency | 90%+ | 20-30% | 60-70% |

| Safety Risk Level | Minimal | High | Moderate |

| Portability | Excellent | Good | Poor |

| Operating Cost | Low | High | Moderate |

The comparison between induction and resistance heating demonstrates clear operational advantages favoring electromagnetic solutions, particularly when lifecycle costs encompassing energy consumption, maintenance labor, and component longevity factor into ROI calculations.

Railway maintenance operations face rigorous oversight from transportation authorities, occupational safety regulators, and environmental agencies—demanding heating equipment that meets comprehensive compliance standards.

Induction heating systems generate powerful electromagnetic fields that could potentially interfere with railway signaling systems, communication equipment, and electronic control modules. Quality equipment incorporates shielding and filtering that limits emissions below regulatory thresholds established by FCC (United States), CE (European Union), and equivalent international standards.

Field strength measurements should be conducted during initial installation, verifying safe exposure levels for operators working in proximity to energized heating coils. Typical safe distances range from 0.5 to 1.0 meters depending on equipment power output and frequency.

Railway workshop electrical systems must accommodate high-power induction equipment while maintaining ground fault protection and preventing electrical hazards. Premium heating systems carry UL, CSA, or IEC certifications validating proper insulation, grounding provisions, and protection against electrical shock.

Facility electrical infrastructure should be evaluated by licensed electricians before equipment installation, ensuring adequate circuit capacity, proper grounding conductors, and appropriate overcurrent protection devices.

Despite inherent safety advantages over flame heating, induction systems still present thermal burn risks and electromagnetic field exposure concerns. Mandatory safety protocols should address:

Regular safety audits conducted by qualified safety professionals ensure ongoing compliance and identify potential hazards before incidents occur.

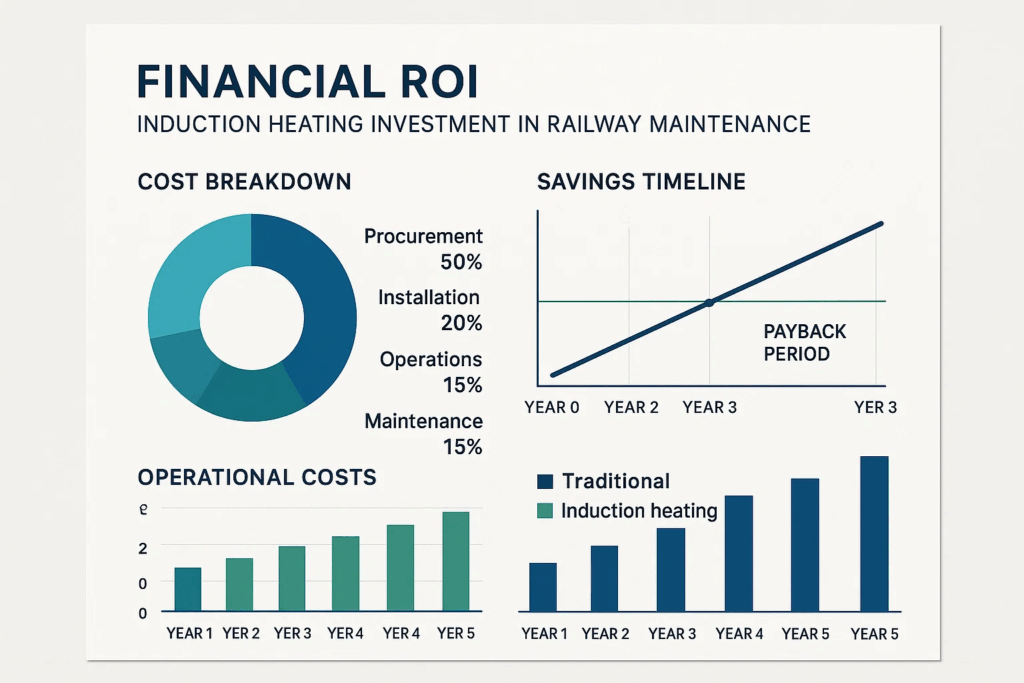

Railway operators evaluating induction heating investments must quantify both direct cost savings and indirect operational benefits that impact fleet availability and maintenance efficiency.

Industrial-grade induction heating equipment represents significant capital expenditure, with pricing varying based on capacity and features:

However, these acquisition costs must be evaluated against total ownership expenses spanning equipment lifespan—typically 15-20 years for quality industrial units with proper maintenance.

Direct energy consumption reductions deliver immediate monthly savings. A typical workshop heating 50 bearings weekly using resistance heaters consumes approximately 2,400 kWh monthly, versus 960 kWh for equivalent induction heating operations—yielding $144-$180 monthly savings at industrial electricity rates.

Labor efficiency gains prove even more significant. Reducing bearing heating times from 4 hours to 45 minutes liberates skilled technicians for higher-value tasks, effectively increasing maintenance capacity 5-fold without adding personnel.

Component longevity improvements stemming from controlled heating reduce unplanned maintenance events and parts replacement costs. Field data from railway operators demonstrates 30-40% reduction in premature bearing failures when transitioning from flame heating to induction methods.

Fleet availability improvements translate directly to revenue generation opportunities—each additional day of locomotive availability generates operational value ranging from $5,000 to $15,000 depending on service type and market conditions.

Conservative financial modeling for mid-sized railway maintenance facilities projects 24-36 month payback periods accounting for capital costs, energy savings, labor efficiency gains, and reduced component replacement expenses. High-utilization operations processing 100+ components monthly often achieve payback within 18-24 months.

Technological advancement continues accelerating within the induction heating sector, with emerging innovations promising enhanced performance, intelligence, and sustainability for railway maintenance operations.

Next-generation induction heaters incorporate internet connectivity enabling remote monitoring, predictive maintenance alerts, and centralized fleet management across multi-site railway operations. Smart induction heating systems transmit real-time operational data to cloud platforms, generating analytics that optimize heating profiles and identify equipment degradation before failures occur.

These intelligent systems automatically update heating programs based on component specifications retrieved from maintenance management systems, eliminating manual data entry errors and ensuring consistent quality across all maintenance locations.

The transition from traditional IGBT power supplies to silicon carbide (SiC) and gallium nitride (GaN) semiconductors delivers dramatic efficiency improvements and reduced equipment footprints. High-efficiency induction heating with SiC/GaN semiconductors achieves 95%+ electrical-to-thermal conversion efficiency while operating at higher frequencies that enable faster heating cycles.

These advanced materials tolerate higher operating temperatures and switching frequencies, enabling more compact power supplies that reduce equipment weight and installation space requirements—particularly valuable for crowded railway workshop environments.

Railway operators pursuing carbon neutrality increasingly demand heating solutions compatible with renewable energy sources. Modern induction systems adapt seamlessly to variable power inputs from solar arrays or wind generation, incorporating battery storage systems that smooth power delivery fluctuations.

Induction heating renewable energy applications demonstrate the technology’s versatility in supporting sustainability initiatives while maintaining operational effectiveness regardless of power source characteristics.

Emerging maintenance platforms overlay digital heating instructions and real-time temperature visualizations onto physical components through AR glasses, guiding technicians through complex heating procedures while monitoring safety parameters continuously.

This technology reduces training requirements for junior technicians while ensuring veteran operators maintain best practices consistently, ultimately improving quality outcomes across entire maintenance organizations.

Bearing inner diameter determines required heater capacity. Bearings under 100mm ID require 3.6-7.2kW units, 100-300mm ID need 10-15kW systems, while components exceeding 300mm ID demand 18-24kW or larger specialized equipment.

Typical heating times range from 15-45 minutes depending on bearing mass and target temperature. A 150mm ID bearing reaches 110°C installation temperature in approximately 25 minutes with appropriate equipment, compared to 2-4 hours using resistance heating methods.

Quality induction equipment meeting CE and FCC electromagnetic compatibility standards generates minimal interference with properly shielded railway electronics. Maintain manufacturer-recommended spacing (typically 2-3 meters) from sensitive signaling and control equipment during operation.

Properly controlled induction heating preserves bearing integrity by maintaining temperatures below tempering thresholds (typically 120°C maximum). Automated temperature monitoring prevents overheating that could reduce bearing hardness or load capacity, unlike flame heating which frequently causes metallurgical damage.

Minimal maintenance beyond weekly visual inspections, monthly calibration verification, and annual professional servicing ensures reliable operation. Quality industrial units operate 10,000+ heating cycles between major service intervals, with typical operational lifespans exceeding 15-20 years.

Railway maintenance operations demand heating solutions that balance precision, safety, efficiency, and reliability across diverse applications spanning routine bearing replacements to complex rotor overhauls. Induction heating technology has evolved from specialized niche equipment to essential infrastructure supporting modern railway maintenance excellence.

Organizations should evaluate induction heating investments through comprehensive frameworks considering immediate operational requirements, long-term fleet expansion plans, and evolving regulatory mandates. Portable systems suit contractors and small operators requiring flexibility, while centralized workshop installations optimize throughput for high-volume maintenance facilities.

The technology’s proven performance advantages—accelerated heating cycles, enhanced component longevity, improved workplace safety, and substantial energy savings—deliver compelling ROI that justifies capital investment across railway operations ranging from light rail transit to heavy freight networks.

As railway systems worldwide modernize fleets and pursue sustainability objectives, induction heating solutions position maintenance organizations for success in increasingly competitive and environmentally conscious transportation markets. The question is no longer whether to adopt induction technology, but rather which configuration best aligns with your specific operational profile and strategic objectives.

Ready to transform your railway maintenance operations? Explore our comprehensive range of industrial induction heating solutions engineered specifically for the demanding requirements of modern railway applications, or discover our specialized induction heaters for the automotive industry that share similar precision requirements.