Unplanned motor failures cost industries millions annually, disrupting production and damaging critical equipment. Traditional maintenance schedules can’t predict when hidden electrical faults will escalate into catastrophic failures. Electrical signature analysis provides real-time diagnostic insights, detecting motor problems before they cause costly downtime all without interrupting operations.

Electrical signature analysis (ESA) is a non-invasive, remote diagnostic technique that assesses the health of rotating equipment like motors and generators by monitoring electrical parameters. Unlike traditional testing methods requiring equipment shutdown, ESA captures voltage and current data while machinery operates normally.

The technology transforms electrical signals into detailed frequency spectrums using advanced algorithms, revealing mechanical and electrical anomalies invisible to visual inspection. ESA records milliseconds of voltage and current waveforms across all three phases, displaying this information as time-based graphs that often reveal power quality issues not apparent through numerical data alone.

Key characteristics of ESA:

For manufacturers seeking comprehensive motor testing solutions, ESA complements traditional methods like surge testing, creating a complete diagnostic strategy.

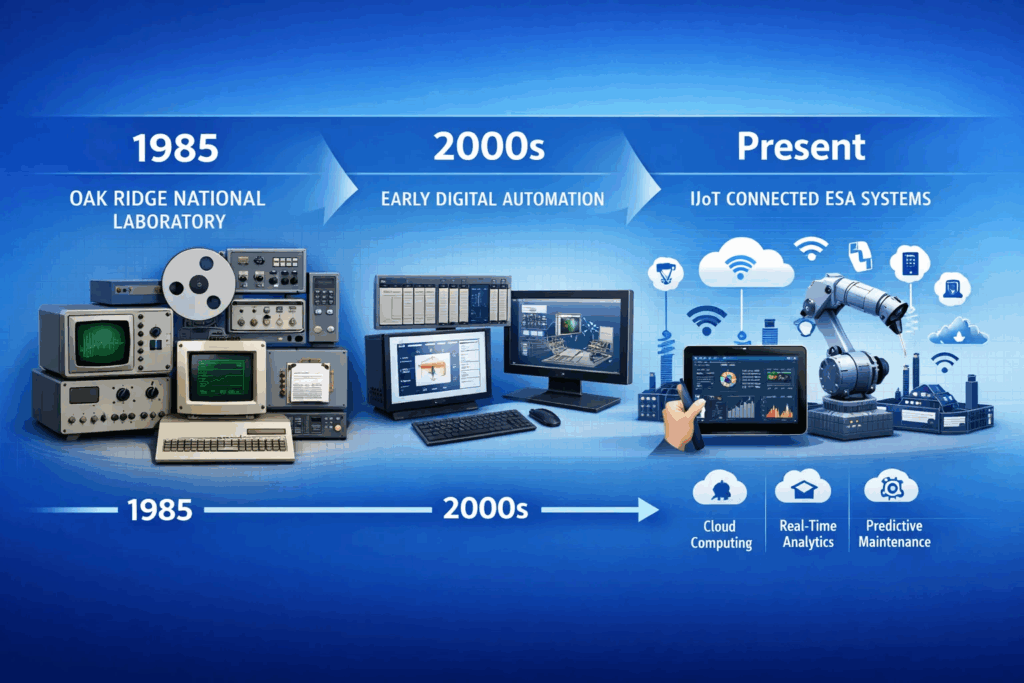

The origins of electrical signature analysis trace back to 1985, when Oak Ridge National Laboratory pioneered Motor Current Signature Analysis (MCSA) to monitor motor-operated valves in nuclear power plants without intrusive procedures. This breakthrough enabled real-time fault detection in critical safety systems.

Evolution timeline:

1985-1990: Initial MCSA development focused exclusively on current monitoring for nuclear applications.

1990s Expansion: ESA evolved to include voltage and power monitoring, expanding its capabilities to pumps, compressors, and other rotating equipment, making it accessible beyond nuclear facilities.

2000s Refinement: Integration of sophisticated frequency analysis algorithms improved fault detection accuracy, particularly for subtle bearing defects and rotor bar issues.

2010s Digital Revolution: Real-time data integration and advanced analytics propelled ESA into predictive maintenance programs, helping operators reduce costs and improve operational efficiency.

Today’s Technology: Modern ESA systems leverage Industrial Internet of Things (IIoT) connectivity and artificial intelligence, delivering automated diagnostics that identify fault patterns humans might miss. This technological advancement positions ESA as essential for industries prioritizing reliability and energy efficiency.

Automated motor testing systems now incorporate ESA principles, combining multiple diagnostic techniques for comprehensive equipment monitoring.

Electrical signature analysis transforms complex electrical data into actionable diagnostic information through a systematic process:

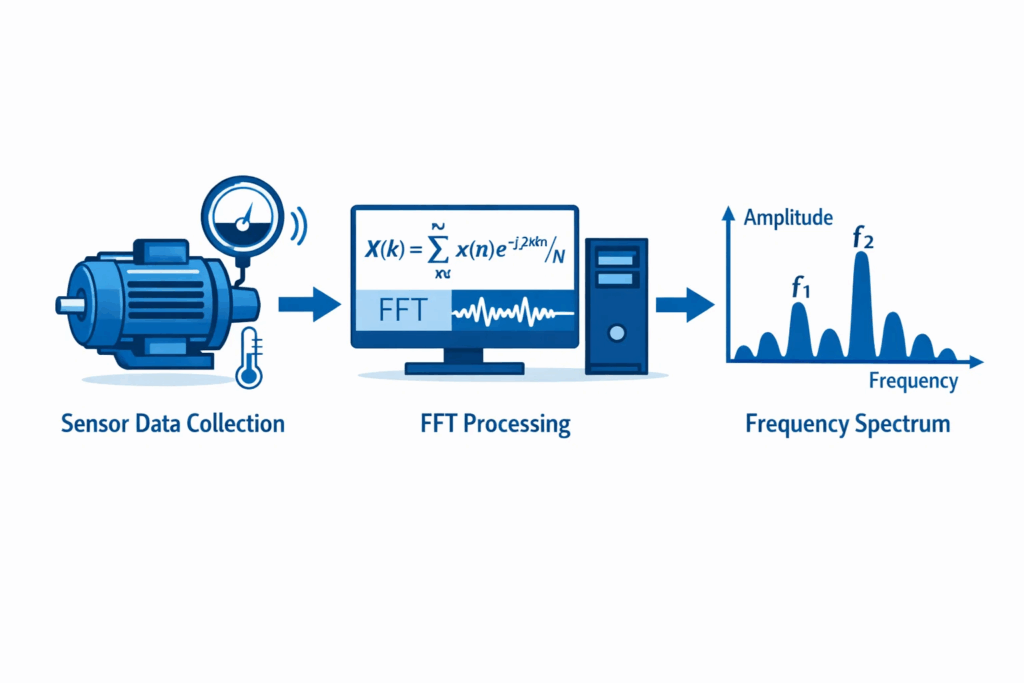

Current and voltage data are collected from motor or generator leads using current or voltage transducers placed at the Motor Control Center. These non-invasive sensors clamp onto power cables without interrupting operation, capturing high-resolution electrical signatures.

The system simultaneously monitors all three phases, ensuring balanced assessment of power quality and load distribution. Data acquisition typically completes in under two minutes per motor, making large-scale facility monitoring practical.

Raw electrical data undergoes Fast Fourier Transform (FFT) analysis to generate frequency spectrums from which equipment component condition information can be extracted. This mathematical transformation reveals periodic patterns corresponding to specific mechanical frequencies.

Advanced analysis techniques include:

Every motor possesses a unique electrical fingerprint reflecting normal operation. Deviations from this baseline signature indicate developing problems. Experienced analysts recognize specific patterns: bearing wear creates distinct sideband frequencies, rotor bar cracks generate characteristic harmonics, and motor winding failures produce asymmetrical current distributions.

Modern ESA software automates much of this interpretation, flagging anomalies and suggesting probable causes based on pattern recognition algorithms.

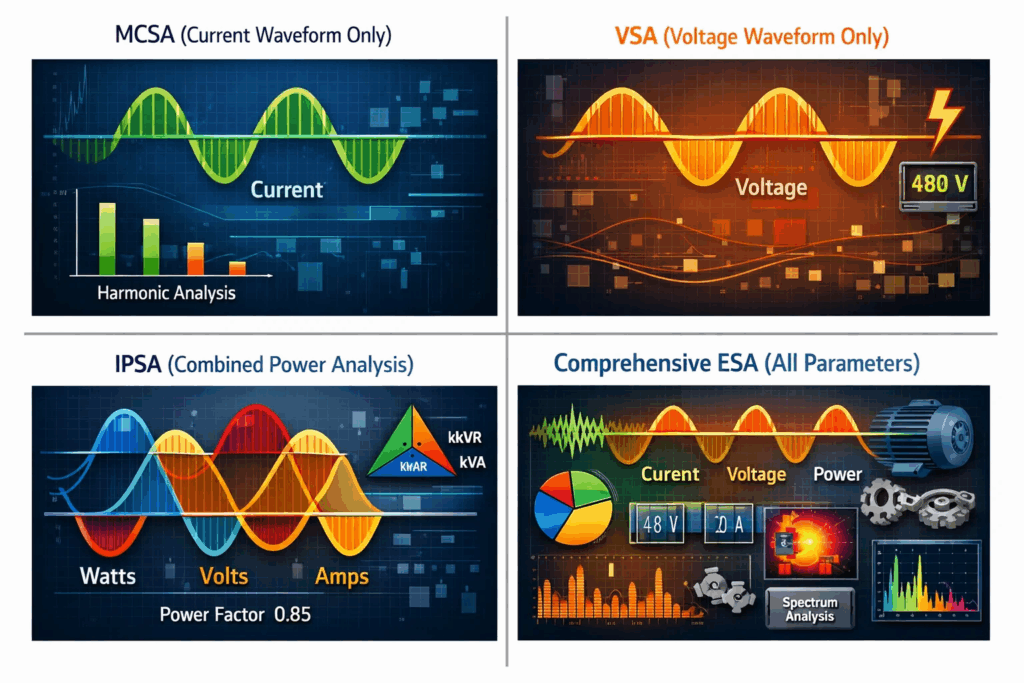

ESA encompasses multiple specialized analysis methods, each providing unique diagnostic capabilities:

The foundational ESA technique, MCSA exclusively monitors current waveforms. It excels at detecting rotor bar defects, air gap eccentricity, and load variations. However, MCSA cannot differentiate whether abnormalities originate from power supply issues or internal motor problems.

VSA examines voltage patterns to identify power quality problems, harmonic distortion, and supply imbalances. When combined with current data, VSA pinpoints whether faults stem from incoming power or equipment degradation.

IPSA combines current and voltage analysis to provide comprehensive characterization of motor and generator health informing maintenance and replacement decisions. This technique offers superior diagnostic accuracy by analyzing the interaction between electrical parameters.

Unlike MCSA which analyzes only current, comprehensive ESA uses both voltage and current data, allowing more accurate determination of whether faults originate from power sources or motor systems. This dual-input approach eliminates ambiguity, accelerating troubleshooting.

Understanding these variations helps maintenance teams select appropriate testing equipment. For facilities using surge testing equipment, ESA provides complementary diagnostics covering different failure modes.

Electrical signature analysis identifies numerous mechanical and electrical anomalies before they escalate into failures:

Regular motor winding testing combined with ESA creates comprehensive diagnostic coverage, catching problems early regardless of origin.

Understanding how electrical signature analysis compares to alternative techniques helps maintenance professionals select optimal diagnostic strategies:

Advantages of ESA:

Vibration Analysis Strengths:

Infrared thermography identifies hotspots indicating excessive resistance or friction, but cannot detect electrical or mechanical issues before they generate heat. ESA reveals problems in earlier development stages, often months before temperature rises.

While surge testing excels at detecting winding insulation weaknesses, it requires equipment de-energization. ESA monitors operating equipment continuously, catching problems surge testing might miss between scheduled tests. Understanding surge tester vs hipot tester differences clarifies complementary diagnostic approaches.

Leading maintenance programs combine multiple techniques:

Electrical signature analysis delivers value across sectors where equipment reliability directly impacts profitability and safety:

High-speed production environments leverage ESA to prevent disruptions. Continuous monitoring detects rotor imbalances in packaging line motors and bearing wear in conveyor systems before failures halt assembly operations.

Power plants use ESA to keep generators, transformers, and power systems running optimally. Nuclear facilities particularly value ESA’s non-invasive monitoring of critical safety systems where access restrictions limit traditional testing.

Offshore platforms and refineries depend on ESA for monitoring pumps, compressors, and drilling equipment in hazardous locations. Remote diagnostic capability reduces personnel exposure to dangerous environments.

Municipal treatment facilities employ ESA to prevent pump failures that could compromise public health. Early cavitation detection protects expensive equipment from erosion damage.

Crushing, grinding, and conveying equipment in remote locations benefits from ESA’s ability to predict failures before spare parts become unavailable, minimizing costly production stoppages.

Railway systems, airports, and shipping facilities use ESA to maintain critical infrastructure motors powering escalators, conveyor systems, and ventilation equipment where downtime affects passenger safety.

Implementing electrical signature analysis delivers quantifiable advantages:

ESA identifies developing problems weeks or months before traditional methods, providing time to schedule repairs during planned maintenance windows rather than responding to emergency failures.

Preventing catastrophic failures saves money multiple ways: eliminating emergency repair premiums, avoiding production losses, and extending equipment lifespan through timely intervention.

Remote monitoring eliminates personnel exposure to energized equipment and hazardous environments. Predictive maintenance reduces risk of fire, explosion, or mechanical failures causing injury.

Continuous monitoring reveals efficiency losses from misalignment, imbalance, or power quality problems. Addressing these issues reduces energy consumption and optimizes performance.

Data-driven decision making replaces guesswork and arbitrary schedules. Maintenance occurs when equipment actually needs attention, not according to calendar intervals.

For facilities concerned about troubleshooting electrical testing errors, ESA’s automated analysis reduces interpretation mistakes common with manual testing methods.

Successfully deploying electrical signature analysis requires strategic planning:

Identify critical assets where failure causes significant impact. Prioritize equipment with:

Choose ESA technology matching facility requirements:

Document electrical signatures of properly functioning equipment. These baselines become reference points for identifying deviations indicating developing problems.

Ensure personnel understand ESA principles, data interpretation, and system operation. Effective implementation requires knowledge beyond equipment operation to include diagnostic reasoning.

Coordinate ESA with existing maintenance programs. Combine insights from vibration analysis, thermography, oil analysis, and visual inspection for comprehensive equipment condition awareness.

Contact Vivid Metrawatt Global to discuss how ESA can complement electrical testing equipment in your predictive maintenance strategy.

No, ESA should complement rather than replace existing testing. While ESA excels at detecting certain electrical and mechanical faults during operation, techniques like surge testing evaluate insulation integrity that ESA cannot directly measure. Comprehensive programs combine multiple diagnostic approaches for complete equipment assessment.

Typical ESA testing captures complete electrical signatures in under two minutes per motor. However, analysis complexity varies with equipment type and suspected problems. Simple screening tests process quickly, while detailed diagnostics for complex fault patterns require more thorough examination.

Modern ESA systems include automated diagnostics identifying common fault patterns and flagging anomalies for investigation. However, understanding electrical and mechanical relationships improves diagnostic accuracy. Training programs typically range from basic operation courses to advanced interpretation workshops for maintenance professionals.

Initial ESA equipment investment generally compares to mid-range vibration analysis systems. However, installation costs are often lower because ESA connects at Motor Control Centers rather than requiring sensor mounting on each machine. Total cost of ownership favors ESA for facilities monitoring large motor populations remotely.

Yes, ESA effectively monitors VFD-powered equipment. Advanced ESA systems filter carrier frequencies and other VFD-induced signals to isolate mechanical and electrical signatures. In fact, ESA can identify VFD problems contributing to motor stress that might be invisible to other diagnostic methods.

Electrical signature analysis represents a paradigm shift in predictive maintenance, transforming motors and generators into intelligent transducers broadcasting their health status continuously. By capturing electrical signatures and applying sophisticated analysis, ESA reveals developing problems long before traditional methods, protecting equipment investments while maximizing operational reliability.

From its nuclear power origins to widespread industrial adoption, ESA has proven indispensable across sectors where unplanned downtime carries significant consequences. The technology’s non-invasive nature, combined with comprehensive diagnostic capabilities, makes ESA an essential component of modern maintenance strategies.

For facilities seeking to implement condition-based maintenance programs, ESA provides the foundation for data-driven decision making. When integrated with complementary techniques like surge testing and vibration analysis, ESA creates comprehensive equipment monitoring that minimizes failures while optimizing maintenance resources.

Ready to enhance your motor diagnostic capabilities? Explore Vivid Metrawatt Global’s comprehensive electrical testing solutions designed to complement ESA monitoring and protect your critical equipment investments.