Every engineer and quality control professional working with electrical equipment faces a critical challenge how do you know if the insulation inside a motor, transformer, or cable will hold up under real-world voltage stress before it fails in the field? A single insulation breakdown can result in catastrophic equipment damage, unplanned and costly downtime, expensive repair bills, and even life-threatening safety hazards for workers and end users alike. This is exactly why Hipot (High Potential) testing exists — it is one of the most reliable, widely adopted, and globally standardized ways to verify electrical insulation integrity before a product ever reaches the end user.

But here is where many professionals get stuck: there are two types of Hipot testing AC and DC and choosing the wrong one can produce inaccurate results, damage sensitive equipment, or even miss critical insulation faults that will eventually cause a failure in service. For manufacturers, repair facilities, and testing laboratories, this is not just a technical decision — it directly impacts product safety, compliance, and reputation.

Understanding the difference between AC Hipot and DC Hipot testing is not just technical knowledge it is essential to making your testing process safe, effective, cost-efficient, and fully compliant with international standards such as IEC, IEEE, and UL. If you want to understand the broader role of Hipot in electrical test systems, start with our guide on What is Hipot in a Digital Surge Tester.

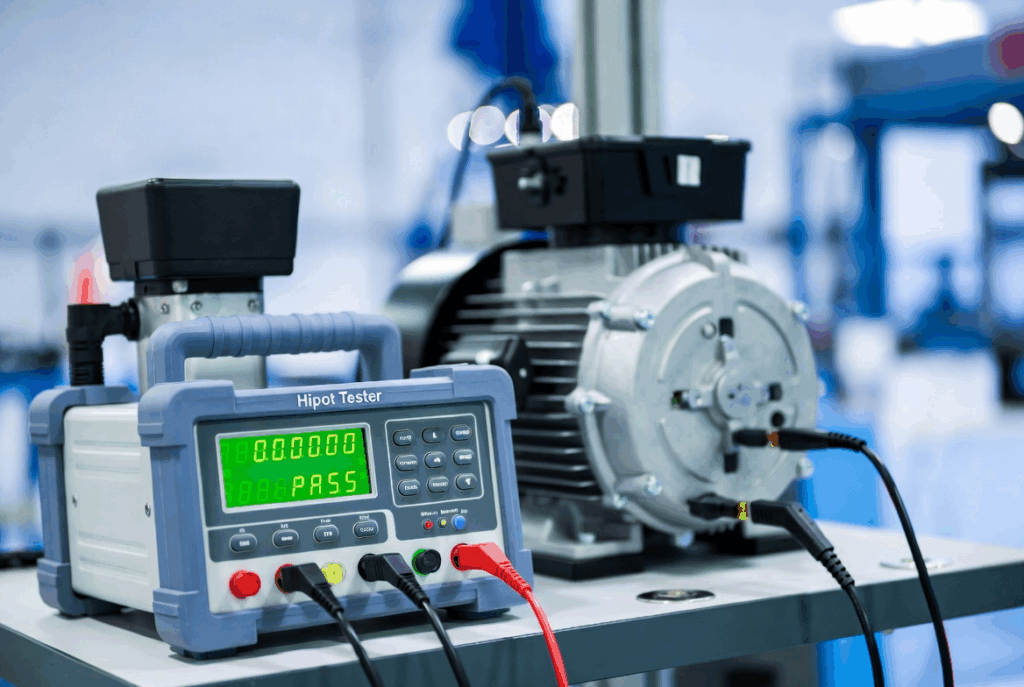

Hipot testing short for High Potential testing involves applying a voltage significantly higher than the normal operating voltage to the insulation of an electrical device. The goal is to deliberately stress the insulation and verify that it does not break down, arc over, or allow excessive leakage current to flow between live conductors and ground or between conductors of different phases.

It is a pass/fail safety test used across motor manufacturing, cable production, transformer assembly, switchgear fabrication, and many other industries where insulation integrity is non-negotiable. When a device passes a Hipot test, it means the insulation can safely withstand voltage surges, transients, and overvoltage conditions that may occur in real-world operation.

Hipot testing is typically performed at the end of the manufacturing process as a 100% production test, and it may also be carried out periodically in the field as part of preventive maintenance programs. Both AC and DC Hipot tests apply elevated voltages, but they behave very differently, stress the insulation in different ways, and are suited to different types of equipment and applications. Understanding what a high voltage test is and how it works lays a strong foundation before diving deeper into the AC vs. DC comparison.

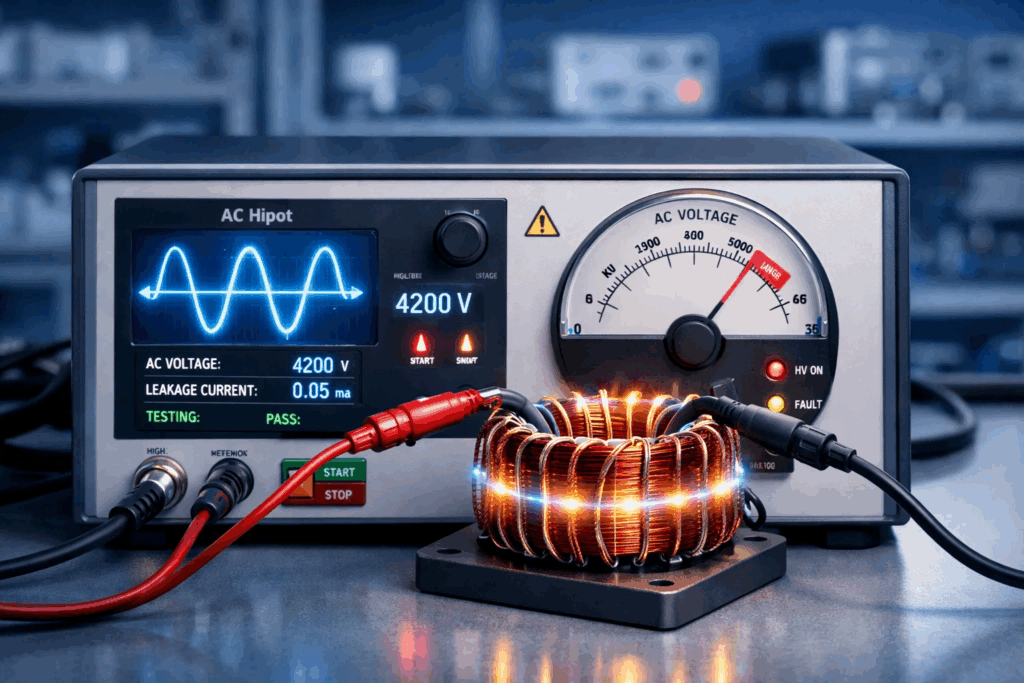

AC Hipot testing applies an alternating current voltage typically at the power frequency of 50 Hz or 60 Hz across the insulation of the device under test (DUT). The voltage rises and falls sinusoidally, which means the insulation is stressed in both positive and negative polarities throughout every cycle of the test duration.

This bidirectional stress is one of the most important characteristics of AC Hipot testing. Since real-world AC-powered equipment experiences voltage stress in both polarities during normal operation, the AC Hipot test accurately replicates this condition and is therefore highly effective at revealing insulation weaknesses that would be triggered during actual use.

Key characteristics of AC Hipot testing:

AC Hipot is the preferred method for testing motors, transformers, switchgear, and cables that will operate on AC power. It is especially effective for detecting turn-to-turn insulation faults and ground insulation weaknesses. Learn how surge tester insulation failure testing complements AC Hipot to provide complete insulation quality assurance throughout the production and maintenance process.

One limitation to be aware of: because AC Hipot measures both capacitive and resistive leakage current together, interpreting the results on high-capacitance devices like long power cables can be more complex. In those cases, DC Hipot may offer a cleaner measurement.

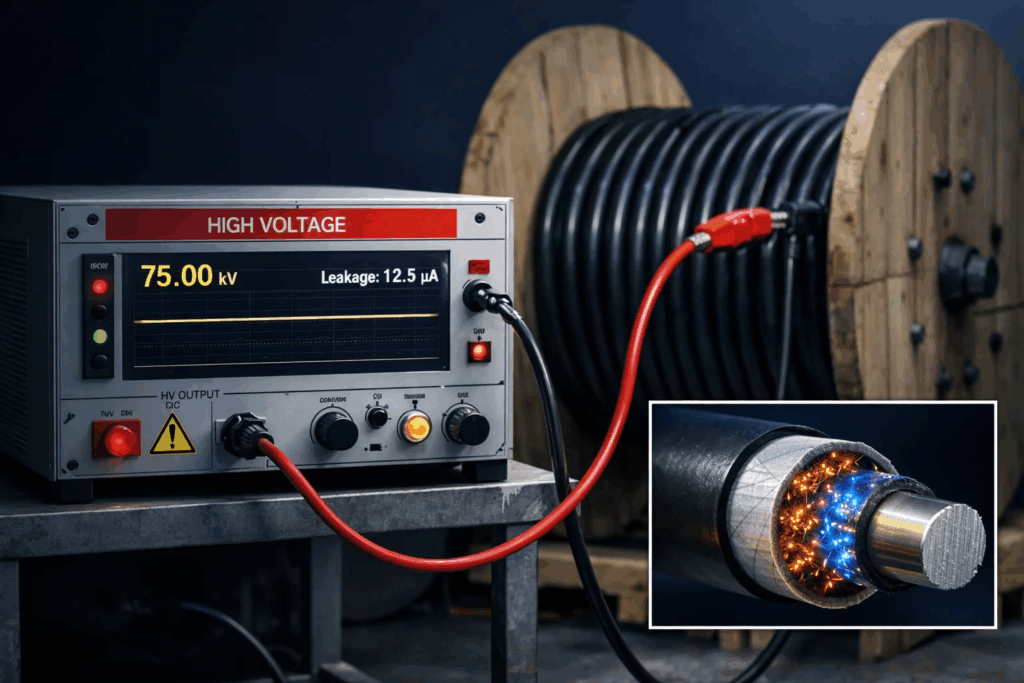

DC Hipot testing applies a steady, unidirectional (direct current) voltage across the insulation of the device under test. Because the voltage does not oscillate, there is no capacitive charging current once the device reaches steady state — meaning the only current measured is the true resistive leakage current flowing through any defects in the insulation.

This makes DC Hipot particularly valuable when you need a very precise, clean measurement of insulation resistance under high-voltage stress. The absence of capacitive current makes it much easier to detect subtle changes in resistive leakage that could indicate insulation aging, moisture ingress, or contamination.

Key characteristics of DC Hipot testing:

One important caveat that engineers must understand: DC Hipot testing can mask certain types of defects that an AC test would reveal. This is particularly true for insulation that has aged or been compromised by moisture, where the AC’s bidirectional stress would expose weaknesses that DC’s unidirectional stress may leave undiscovered. For a broader comparison of how different high-voltage test methods detect faults differently, see our article on the difference between impulse and surge voltage testing.

Understanding the fundamental differences helps you make the right testing decision for your specific application. Here is a clear side-by-side comparison:

| Feature | AC Hipot | DC Hipot |

|---|---|---|

| Voltage Type | Alternating (sinusoidal) | Direct (unidirectional) |

| Leakage Current Measured | Capacitive + Resistive | Resistive only |

| Insulation Stress Direction | Both polarities | Single polarity |

| Test Voltage Level | Lower | Higher (×1.414 vs. AC equivalent) |

| Best For | Motors, transformers, windings | Long cables, high-capacitance devices |

| Risk of Damage to Equipment | Moderate | Lower for high-cap equipment |

| Fault Detection Coverage | Broader — resistive and capacitive | More specific to resistive faults |

| Post-Test Discharge Required | No | Yes — for high-capacitance specimens |

| Diagnostic Information | Pass/Fail leakage | Leakage trending, step-voltage analysis |

| IEC/IEEE Standard Preference | Preferred for rotating machines | Preferred for cables and DC systems |

The choice between AC and DC is rarely arbitrary — it should be driven by the type of equipment, its operating voltage type, capacitance level, and the specific insulation defects you are trying to detect.

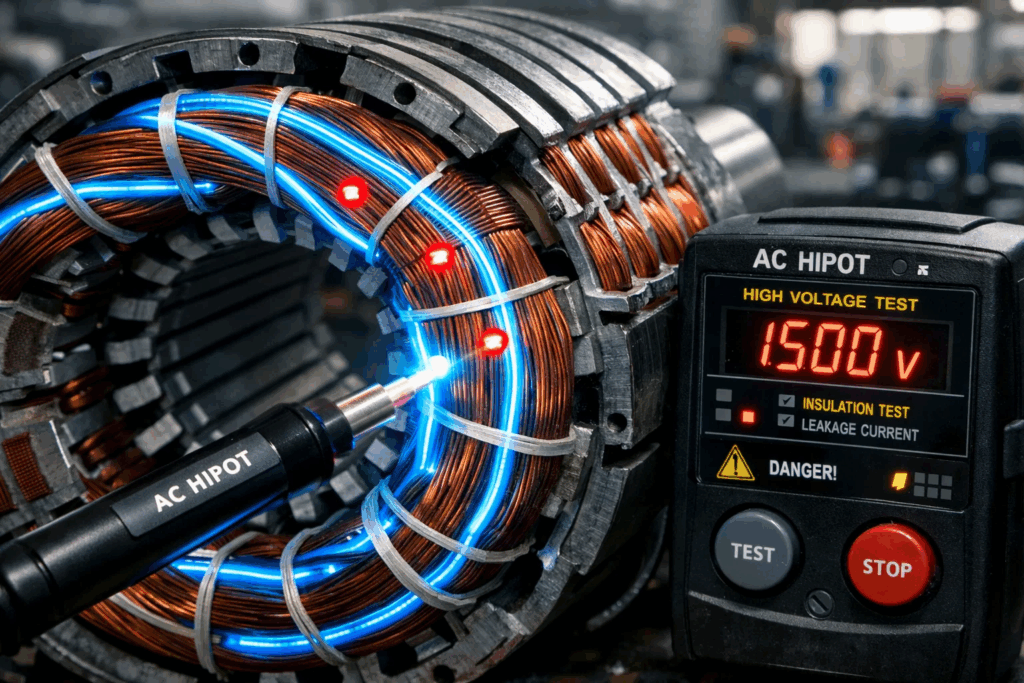

For motor windings, AC Hipot is generally the preferred and most widely recommended method. This is because motor windings operate under AC conditions, and the alternating high-voltage stress of the AC Hipot test closely simulates what the insulation experiences during normal operation and under transient overvoltage conditions.

AC Hipot is particularly effective at revealing inter-turn insulation weaknesses, ground wall insulation defects, and phase-to-phase insulation faults — all of which are common failure modes in electric motors. The test produces results that are directly comparable to the IEC 60034 and IEEE 112 standards for rotating machine insulation testing.

If you are already experiencing issues with motor windings or suspect insulation degradation, understanding motor winding failure signs can help you decide when and how Hipot testing should be part of your diagnostic process. Early detection of insulation weakness through Hipot testing can prevent catastrophic winding failures that result in complete motor burnout.

For a complete picture of motor insulation testing, pairing Hipot with surge testing is highly recommended for maximum fault detection coverage. A surge test detects turn-to-turn insulation faults that Hipot alone may not find, while Hipot verifies ground wall insulation integrity. Read our detailed comparison of surge tester vs. Hipot tester to understand exactly how these two methods complement each other in a complete motor quality assurance program.

Partial discharge (PD) is a localized dielectric breakdown within the insulation that does not bridge the full insulation gap completely — yet. It is one of the earliest and most reliable warning signs of insulation degradation, and it is particularly relevant for medium and high-voltage equipment operating above 1 kV, such as large industrial motors, generators, and high-voltage transformers.

Standard Hipot testing is a go/no-go pass/fail test — it tells you whether insulation has already broken down, but it may not reveal the slow, progressive deterioration caused by partial discharge activity that will eventually lead to failure. This is a significant limitation of standalone Hipot testing for high-voltage equipment.

Incorporating PD detection testing alongside Hipot provides a much more complete and early-warning-capable insulation health picture. PD measurements can identify voids, delamination, surface tracking, and contamination within the insulation before they reach the critical threshold that triggers a Hipot failure. Our detailed partial discharge testing guide explains when and how to integrate PD testing into your quality control and condition monitoring workflow for maximum equipment reliability.

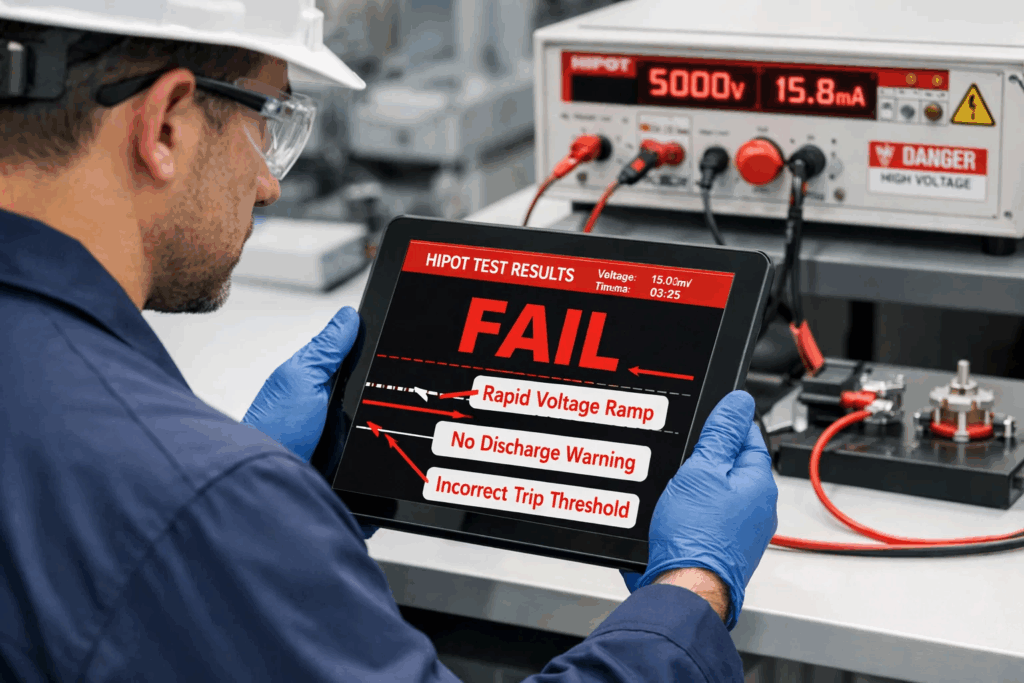

Both AC and DC Hipot tests can produce misleading, unreliable, or even dangerous results if not performed correctly. Many insulation failures are either missed or falsely triggered due to avoidable testing errors. Being aware of these pitfalls is essential for any testing professional.

Common mistakes include applying voltage too quickly without an adequate ramp rate, which causes transient charging currents that can falsely trip the leakage current threshold. Failing to account for the effects of temperature and ambient humidity on leakage current is another frequent error — warm, humid conditions increase capacitive leakage in AC testing and can cause borderline samples to fail incorrectly. Using incorrect trip current thresholds that are too tight for capacitive equipment, or too loose to detect real faults, is also a widespread problem.

For DC testing specifically, not properly discharging high-capacitance specimens after the test creates a very serious electric shock hazard for operators. Skipping a pre-test insulation resistance (Megger) check is another common oversight — a quick IR test before Hipot helps identify severely degraded insulation that could fail explosively under high voltage, protecting both the equipment and the operator.

For a comprehensive look at avoiding mistakes in the broader electrical testing process, our guide on troubleshooting electrical testing errors is an essential read for quality engineers and test technicians alike.

Hipot testing is rarely used in isolation in a professional motor manufacturing or repair environment. A robust, comprehensive motor quality assurance process typically combines multiple test methods in a specific sequence to maximize fault detection coverage across all possible failure modes — insulation resistance (Megger) testing, surge testing, winding resistance measurement, no-load run testing, and Hipot testing all play distinct and complementary roles.

The typical recommended sequence is: first perform a winding resistance measurement to check for open circuits and inter-phase balance, then perform an insulation resistance test to screen for severely degraded insulation before applying high voltage, followed by a surge test to detect turn-to-turn insulation faults, and finally a Hipot test to verify ground wall insulation integrity under high-voltage stress. This layered approach ensures that no category of insulation defect goes undetected.

Start by learning how to test motor windings for a complete step-by-step overview of the motor testing process. You should also understand the difference between Megger and surge testing for windings to see how each method fills a different gap in insulation fault detection. For manufacturers looking to scale up their testing capabilities, understanding automated motor testing systems shows how AC Hipot, DC Hipot, surge testing, and resistance measurement can all be integrated into a single automated test station for high-volume production environments.

For selecting the right testing instrument that supports all these test modes, our guide on what is a surge tester explains the core equipment involved in winding quality testing and how to evaluate tester specifications for your application.

For AC Hipot testing, the standard formula is typically 2× the rated operating voltage + 1000V, held for 60 seconds (per IEC 60034-1 for rotating machines). For DC Hipot, you need 1.414× the AC test voltage to achieve equivalent peak stress — for example, if AC Hipot requires 2500V, the equivalent DC Hipot would be approximately 3535V. Always consult the applicable product standard for your specific equipment type.

Technically yes, but it is not recommended as the primary test method for AC equipment. DC Hipot will verify resistive insulation integrity but may miss defects that only reveal themselves under bidirectional AC stress. If you must use DC Hipot on AC equipment (such as for field testing where AC sources are impractical), use 1.6-1.7× the rated AC voltage and understand that it provides less complete fault coverage than an AC test.

For production testing, the standard duration is typically 60 seconds at full test voltage after a controlled ramp-up period (usually 5-10 seconds). For field maintenance testing on used equipment, longer durations of 1-3 minutes may be specified to detect slow-developing leakage paths. Some standards allow for shorter test times (as low as 1 second) if the test voltage is increased proportionally — check your applicable standard.

There is no universal leakage current limit — it depends entirely on the size, type, and capacitance of the device under test. For small motors, acceptable AC Hipot leakage might be 1-5 mA, while large transformers or long cables could have 50-100 mA of capacitive leakage and still pass. DC Hipot leakage should be much lower (typically under 1 mA for most equipment) since capacitive current is eliminated. The key is trending — sudden increases in leakage indicate degradation.

When performed correctly at the specified voltage and duration, Hipot testing is considered non-destructive and will not damage healthy insulation. However, if insulation is already severely degraded or contaminated, the high-voltage stress may accelerate failure — which is actually the intended purpose of the test: to find weak insulation before it fails in service. Repeated overvoltage testing beyond standards or excessive test durations can cumulatively degrade insulation over time.

For low-capacitance devices like small motors, discharge is not critical after AC Hipot since capacitive charge dissipates quickly. However, for high-capacitance equipment like large cables or capacitor banks, always use a discharge rod or automatic discharge circuit even after AC testing. For DC Hipot, discharge is mandatory for all high-capacitance devices — stored DC charge can remain lethal for minutes or even hours.

DC Hipot is generally considered safer for high-capacitance equipment because it stores less energy (E = ½CV²) during the test, reducing arc blast risk if a failure occurs. However, DC requires mandatory post-test discharge procedures. AC Hipot is safer in terms of natural charge dissipation but carries higher instantaneous current risk during a breakdown event. Both require proper safety protocols, grounding, interlocks, and operator training.

No — properly conducted Hipot testing following applicable standards will not damage good insulation. The test voltage is carefully calculated to stress the insulation beyond normal operating conditions but well below the design strength of healthy insulation. If a device fails Hipot, it means the insulation was already defective or degraded and would likely have failed in service, possibly catastrophically.

Major standards include IEC 60034-1 (rotating electrical machines), IEEE 112 (motor testing), IEC 60060 (high-voltage test techniques), IEC 62368-1 (audio/video and IT equipment), UL 1310 (Class 2 power units), and IEC 60950 (IT equipment). For cable testing, IEC 60502 and IEEE 400 provide guidance. Always verify which standard applies to your specific product category and market.

For new production, Hipot is typically a 100% end-of-line test performed on every unit. For field maintenance, the frequency depends on the equipment type, operating environment, and criticality — annual testing is common for critical motors and transformers, while less critical equipment may be tested every 3-5 years. Trending insulation resistance (Megger) readings between Hipot tests helps determine optimal test frequency.

AC Hipot and DC Hipot testing are both powerful and essential tools for verifying electrical insulation integrity — but they are not interchangeable, and selecting the right method for each application is critical. AC Hipot more closely mimics real-world AC operating conditions, provides bidirectional insulation stress, and delivers broader fault detection coverage for motors, transformers, and wound components. DC Hipot, on the other hand, offers cleaner, more precise leakage current measurement and lower energy storage risk — making it the ideal choice for high-capacitance devices like long power cables, DC systems, and switchgear.

The right choice depends on your equipment type, its normal operating voltage type, the capacitance of the device under test, the specific insulation defects you are targeting, and the international standards applicable to your product. In many professional testing environments, both AC and DC Hipot are used together as complementary methods — each providing unique and non-redundant diagnostic value.

At Vivid Metrawatt Global, we offer advanced, industry-leading testing solutions that support both AC and DC Hipot methodologies — seamlessly integrated with surge testing, partial discharge detection, insulation resistance measurement, and fully automated motor testing systems. Whether you are a motor manufacturer, repair facility, or maintenance professional, our team can help you design the right insulation testing protocol for your specific application. Contact us today to find the right Hipot and insulation testing solution that meets your quality, safety, and compliance requirements.

Explore more technical resources at vividmetrawattglobal.com