Gear failures in automotive transmissions, industrial machinery, and wind turbines create operational disruptions that cascade through entire production systems. Traditional furnace-based heat treatment methods struggle to deliver the precision, consistency, and speed modern manufacturing demands. Induction heating transforms gear hardening by delivering targeted electromagnetic energy directly to tooth surfaces, creating hardened cases in seconds while maintaining ductile cores, eliminating distortion, and enabling inline production integration that conventional methods cannot match.

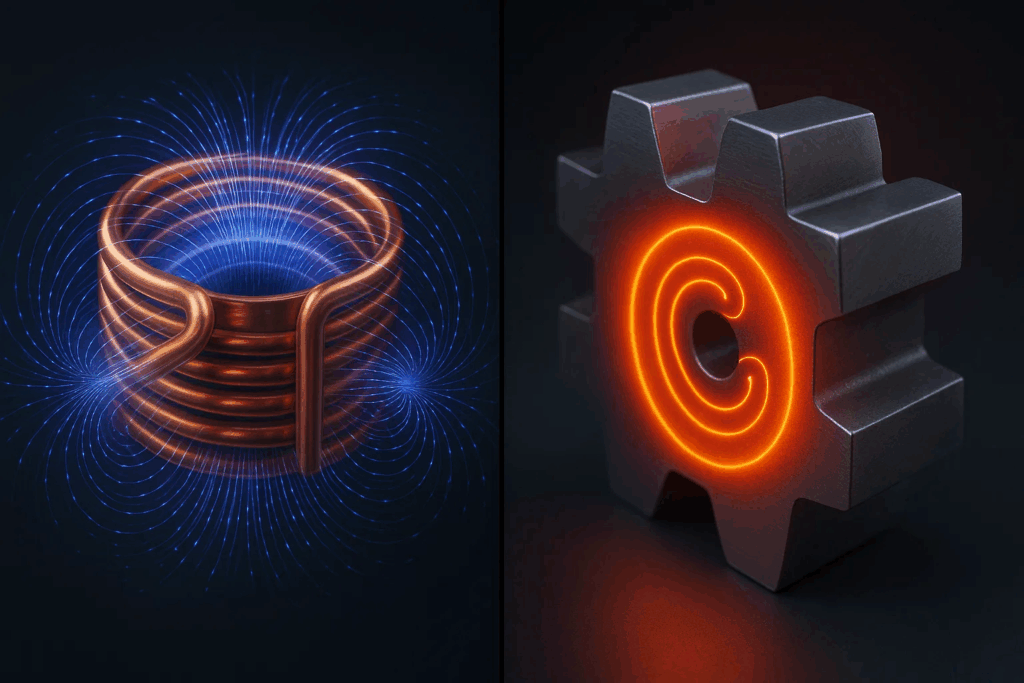

Induction heating operates through electromagnetic induction principles discovered by Michael Faraday in 1831, applying these scientific foundations to modern gear manufacturing challenges. The process generates heat directly within gear materials through alternating magnetic fields, eliminating contact heating methods and enabling precise control over temperature distribution.

Alternating magnetic fields created by copper induction coils induce eddy currents within conductive gear materials. These circulating electrical currents encounter resistance flowing through the steel, converting electrical energy to thermal energy through resistive heating. The heating effect concentrates in surface layers where current density reaches maximum levels.

Frequency selection determines heating depth through the skin effect phenomenon. Higher frequencies produce shallower heating penetration, ideal for case hardening gear tooth surfaces. Lower frequencies penetrate deeper into material cross-sections, appropriate for through-hardening applications. Understanding electromagnetic induction principles enables optimal process design.

Magnetic materials like steel generate additional heat below the Curie point through hysteresis losses as magnetic domains repeatedly align with alternating fields. This supplementary heating mechanism enhances efficiency when processing ferromagnetic gear materials, accelerating heating cycles and improving energy utilization.

Eddy current heating provides the primary heat generation mechanism in induction processing. Current magnitude depends on material electrical resistivity, magnetic permeability, frequency, and coil power density. Engineers manipulate these parameters optimizing heating patterns for specific gear geometries and metallurgical requirements.

Power density distribution across gear tooth profiles determines hardening pattern uniformity. Coil design coordinates electromagnetic field distribution with gear geometry ensuring consistent energy delivery to all tooth surfaces. Proper design prevents soft spots while avoiding overheating at edges and corners.

Heating rate control enables precise temperature management through power level adjustment and exposure time regulation. Rapid heating minimizes grain growth maintaining fine microstructures, while controlled rates ensure complete austenite transformation throughout targeted hardening zones.

Modern induction heating technology delivers precise electromagnetic energy control enabling consistent gear hardening results across production volumes.

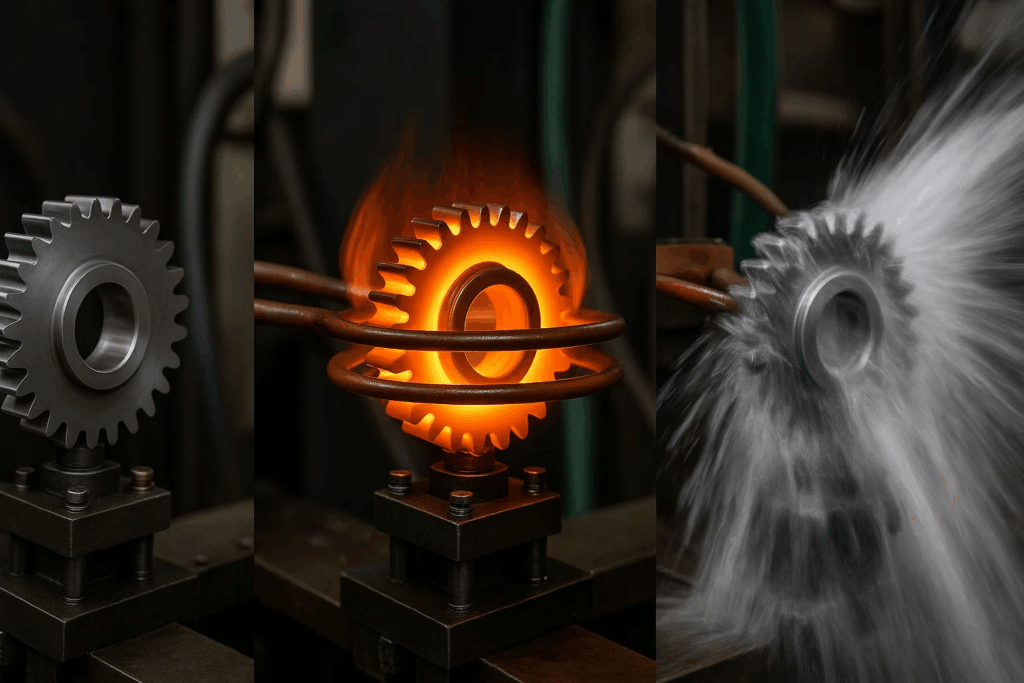

Gear hardening through induction heating follows systematic sequences transforming material properties through controlled thermal cycles. Understanding each process stage enables optimization delivering required mechanical properties while maintaining dimensional accuracy.

Austenite transformation occurs as gear teeth reach critical temperatures where crystal structure transitions from body-centered cubic ferrite to face-centered cubic austenite. This transformation enables carbon dissolution into solid solution, preparing material for subsequent hardening through quenching.

Temperature uniformity across complex gear tooth geometries requires careful coil design and power distribution control. Three-dimensional electromagnetic simulation optimizes inductor configurations ensuring consistent heating from root to tip and across face width, preventing under-hardened zones compromising performance.

Heating time optimization balances transformation completion against grain growth prevention. Rapid heating cycles characteristic of induction processing minimize high-temperature exposure preventing excessive grain coarsening that reduces toughness. Typical heating times measure in seconds rather than minutes or hours required by furnace methods.

Rapid cooling transforms austenite to hard martensitic microstructure through quenching immediately following heating. Cooling rate exceeds critical transformation velocity preventing formation of softer structures like pearlite or bainite. Water-based polymer quenchants provide optimal cooling characteristics balancing hardness achievement against crack prevention.

Quench system design delivers controlled cooling media application through precisely positioned spray patterns. Modern systems employ programmable flow rates, pressures, and concentrations optimizing cooling uniformity while preventing thermal shock. Integration of heating and quenching within single stations eliminates transfer delays preserving elevated temperatures.

Distortion control benefits from induction heating’s localized thermal input and rapid cycles. Minimal bulk heating reduces dimensional changes while quick processing limits time for thermally-induced warping. Proper fixturing and quench design further minimize distortion maintaining gear accuracy within tight tolerances.

Stress relief through tempering reduces brittleness in hardened cases while improving toughness and dimensional stability. Reheating hardened gears to intermediate temperatures relieves residual stresses and transforms some retained austenite to more stable microstructures without significantly reducing surface hardness.

Induction tempering applies the same electromagnetic heating principles used for hardening but at lower temperatures and power levels. The process offers speed and control advantages over furnace tempering while enabling selective tempering of previously hardened zones without affecting entire gear bodies.

Microstructure optimization through tempering balances hardness retention against improved toughness and fatigue resistance. Temperature and time parameters determine final mechanical property combinations meeting application-specific performance requirements.

Induction heating delivers substantial benefits compared to traditional furnace-based gear heat treatment, transforming production economics while improving metallurgical results and environmental impact.

Heating cycle reduction from hours to seconds revolutionizes production throughput. Gears reach hardening temperatures in 3-15 seconds compared to 30-90 minutes in batch furnaces, dramatically increasing daily production capacity. This speed advantage enables inline processing eliminating separate heat treatment operations.

Energy efficiency improvements stem from heating only required zones rather than entire gear masses and surrounding furnace structures. Electromagnetic energy couples directly into workpieces with minimal losses, achieving 70-90% electrical-to-thermal conversion efficiency compared to 15-40% for gas-fired furnaces.

No warmup delays characterize induction systems operating at full capacity instantly without preheating requirements. Production starts and stops accommodate changing schedules without energy waste or productivity loss maintaining cold equipment. This flexibility supports lean manufacturing and just-in-time production strategies.

Fine grain structures result from rapid heating limiting time for grain growth at elevated temperatures. Fine grains improve mechanical properties including strength, toughness, and fatigue resistance compared to coarse structures developed during prolonged furnace exposure.

Minimal decarburization preserves surface carbon content critical for maximum hardness achievement. Heating in air without protective atmospheres normally causes carbon loss from surfaces, but induction’s brief exposure prevents significant decarburization. Surface integrity maintenance eliminates grinding operations removing decarburized layers.

Selective hardening capability enables targeted strengthening of gear tooth surfaces while maintaining ductile, tough cores. This property gradient optimizes performance providing wear resistance where needed and impact absorption capacity preventing brittle fracture. Selective hardening proves impossible with through-hardening furnace methods.

Reproducibility improvements follow from precise electromagnetic heating control and automated process parameters. Computer-controlled power, frequency, and timing eliminate operator variability ensuring identical treatment for every component. Statistical process control data demonstrates capability indices exceeding traditional methods.

Reduced distortion minimizes post-hardening machining requirements and scrap from out-of-tolerance parts. Localized heating and rapid cycles limit thermal gradients and material expansion preventing warping. Many gears require no straightening operations after induction hardening.

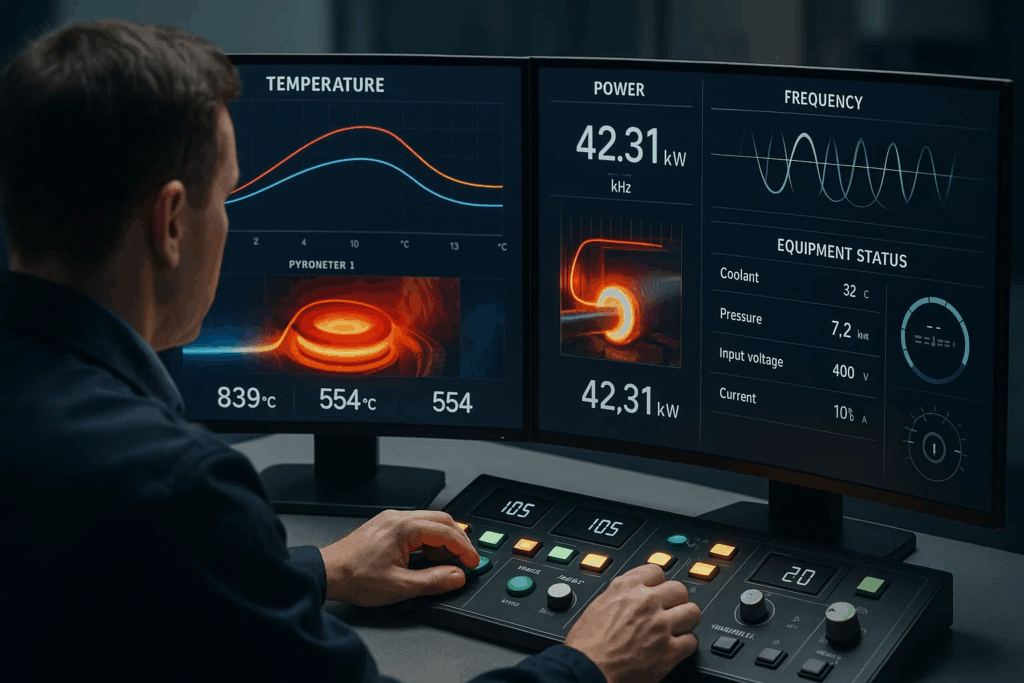

Real-time monitoring through pyrometers and power meters provides immediate feedback enabling process adjustments maintaining specifications. Modern systems log complete thermal history for every gear supporting quality documentation and continuous improvement initiatives.

Understanding proper induction coil design principles ensures optimal heating patterns and consistent results.

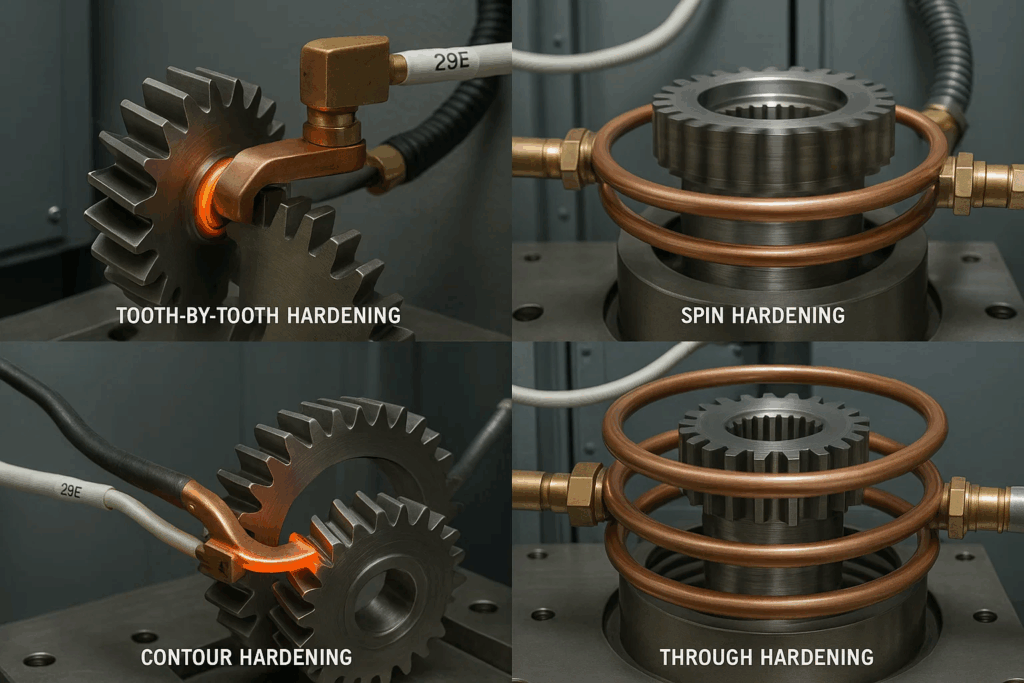

Different gear geometries, sizes, and application requirements demand specialized induction hardening approaches. Modern induction technology offers multiple techniques optimizing results for specific gear configurations.

Single tooth processing employs small inductors treating individual gear teeth sequentially. The method provides maximum control over heating patterns enabling steep hardness gradients and precise case depth control. Tooth-by-tooth approaches suit large gears where simultaneous heating proves impractical.

Indexing mechanisms rotate gears positioning successive teeth into heating coils. Programmable indexers ensure accurate positioning while cycle timers coordinate heating, quenching, and rotation sequences. Complete gear hardening occurs within minutes despite sequential processing.

Pattern flexibility allows selective hardening of partial tooth surfaces like flanks only or root areas independently. This capability enables optimization for specific loading patterns and failure modes encountered in service.

Simultaneous tooth heating characterizes spin hardening where inductors encircle entire gear peripheries heating all teeth concurrently. Gears rotate within coils ensuring circumferential uniformity while quench rings apply cooling media uniformly to all surfaces.

Production speed advantages make spin hardening ideal for medium-sized gears in high-volume manufacturing. Complete hardening cycles execute in seconds supporting automotive transmission and industrial gearbox production requirements.

Equipment configurations range from vertical spindle machines for small gears to horizontal systems for large diameter components. Dual-frequency generators enable simultaneous root and flank hardening with different penetration depths optimizing property distributions.

Profile-following inductors match complex gear tooth geometries delivering uniform heating across variable cross-sections. Custom coil designs address involute tooth forms, helical angles, and tip modifications maintaining consistent gap dimensions as critical factor for uniform heating.

Gap scanning technology maintains optimal inductor-to-gear spacing throughout processing despite geometric variations. Servo-controlled positioning systems track tooth profiles preventing overheating at edges while ensuring adequate energy coupling at roots.

Large gear capabilities extend induction hardening to diameters exceeding several meters for wind turbine, mining equipment, and marine propulsion applications. Scanning approaches economically treat these massive components impossible to heat simultaneously.

Complete cross-section transformation occurs when hardening applications require full gear body hardness rather than case-hardened surfaces. Lower frequency induction heating penetrates entire tooth thickness transforming complete volumes to martensitic microstructures.

Small gear applications benefit from through hardening simplicity avoiding complex case depth control. Uniform properties throughout cross-sections suit applications where surface loads remain moderate but overall strength requirements remain high.

Material selection for through hardening emphasizes medium carbon alloys providing adequate hardenability ensuring complete martensitic transformation throughout sections. Higher alloy contents extend hardenability enabling through hardening of larger cross-sections.

Specialized techniques including induction hardening processes address diverse gear manufacturing requirements across industries.

Successful gear induction hardening requires careful selection and control of numerous technical parameters influencing heating patterns, transformation completion, and final properties. Modern systems integrate sophisticated monitoring and control enabling consistent results.

Power frequency considerations range from line frequency (50/60 Hz) through radio frequencies (100-500 kHz) addressing different penetration depth requirements. Medium frequencies (1-10 kHz) suit most gear tooth hardening applications providing appropriate case depths without excessive power requirements.

Skin depth calculations guide frequency selection based on desired hardening penetration. Electromagnetic skin depth equations relate frequency, material resistivity, and permeability to heating depth enabling predictive process design.

Multi-frequency approaches employ simultaneous application of different frequencies targeting various tooth zones. Dual-frequency systems harden roots at lower frequency while treating flanks at higher frequency, optimizing property distributions across complex profiles.

Energy input calculations determine power levels achieving required heating rates within available processing times. Surface power density typically ranges from 1-5 kW/cm² for gear hardening applications balancing heating speed against temperature uniformity maintenance.

Generator sizing considers both power requirements and frequency capabilities. Solid-state inverters provide precise power control with rapid response enabling sophisticated heating profiles. Modern generators deliver 5 kW to several megawatts addressing diverse gear sizes.

Coupling efficiency optimization through proper coil design and gap control maximizes energy transfer from inductors to gears. Poor coupling wastes energy requiring higher generator power while creating non-uniform heating patterns.

Pyrometry applications monitor surface temperatures providing feedback for power control systems. Infrared sensors detect thermal radiation from heated surfaces enabling non-contact temperature measurement during processing. Two-color pyrometers compensate for emissivity variations improving accuracy.

Closed-loop control automatically adjusts power maintaining target temperatures despite variations in part size, initial temperature, or placement. PID controllers process pyrometer signals modulating generator output achieving precise temperature regulation.

Temperature profiling across gear faces ensures uniform transformation throughout tooth surfaces. Multiple pyrometer positions monitor different zones enabling spatial temperature control preventing cold spots and overheating.

Media selection balances cooling intensity against crack susceptibility. Water-polymer solutions provide adjustable cooling characteristics through concentration variation. Typical polymer concentrations range from 5-20% offering cooling rates between water and oil.

Flow rate control determines heat extraction intensity and uniformity. Programmable flow systems vary delivery rates throughout quenching cycles optimizing cooling patterns. Initial high flows quickly reduce surface temperatures before moderate flows complete transformation.

Spray pattern design ensures complete coverage of hardened zones with overlapping patterns preventing dry spots causing soft areas. Multiple spray rings address complex geometries delivering media from various angles.

Modern railway induction heating solutions demonstrate advanced process control applications in demanding industrial environments.

Material selection significantly influences induction hardening effectiveness and final gear performance. Different steel compositions respond differently to rapid induction heating cycles requiring process adaptation for optimal results.

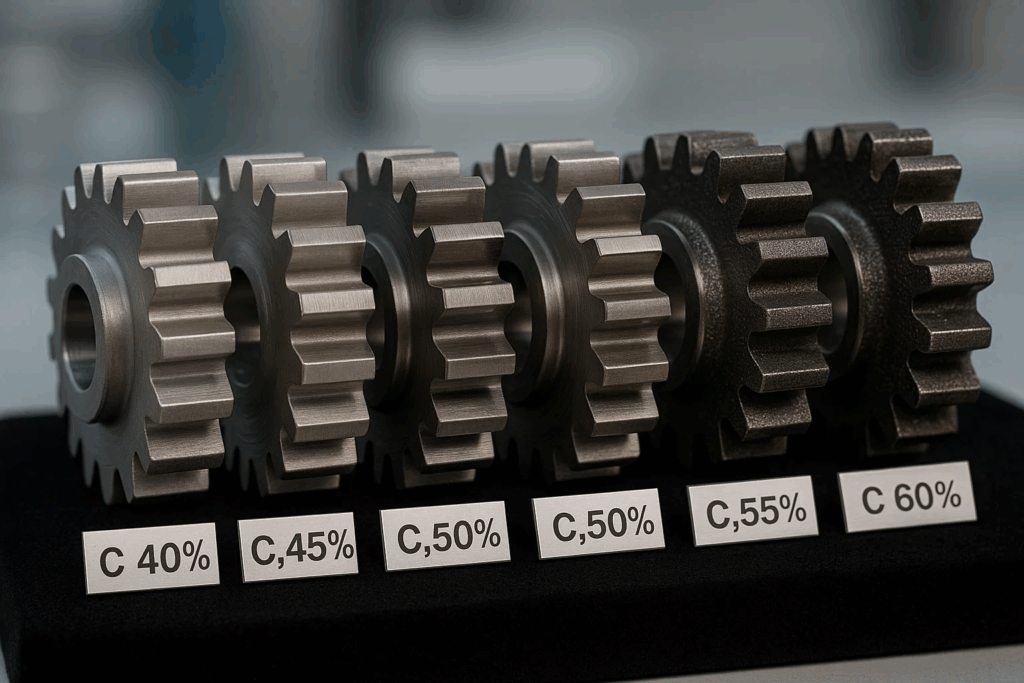

Medium carbon steels (0.40-0.60% C) represent standard gear materials offering good hardenability, reasonable cost, and balanced properties. Carbon content directly determines maximum achievable surface hardness with higher carbon enabling greater hardness through increased martensite carbon supersaturation.

Low carbon limitations restrict hardness achievement in steels below 0.35% carbon. While induction heating successfully transforms these alloys to martensite, maximum hardness remains insufficient for highly loaded gear applications. Carburizing pre-treatment can elevate surface carbon before induction hardening.

High carbon consequences above 0.65% increase crack susceptibility during quenching. Excessive carbon promotes martensite embrittlement and retained austenite formation requiring careful quench design and tempering. Special alloys address high hardness requirements without excessive carbon.

Hardenability enhancers including chromium, molybdenum, and manganese improve transformation characteristics enabling through hardening of larger sections and reducing critical cooling rates. Enhanced hardenability permits slower quenching reducing crack risk while achieving full hardness.

Grain refiners like vanadium and titanium maintain fine grain structures during heating improving mechanical properties. Fine grains particularly benefit rapid induction heating where brief exposure limits grain growth opportunities.

Machinability additives including sulfur and lead facilitate pre-hardening machining but can compromise surface integrity. Induction heating’s minimal decarburization proves advantageous with free-machining grades avoiding extensive surface removal operations.

Application loading analysis determines required surface hardness, case depth, and core properties guiding steel grade selection. Contact stresses, bending loads, and impact conditions define minimum property requirements balanced against material and processing costs.

SAE 1045 and 1050 represent economical choices for moderate-duty gears providing adequate response to induction hardening. These plain carbon grades offer good machinability and hardening response for general industrial applications.

SAE 4140 and 4340 deliver enhanced properties through alloy additions supporting demanding automotive and aerospace applications. Chromium and molybdenum improve hardenability, strength, and toughness justifying premium costs for critical components.

Proper steel material selection for induction hardening ensures optimal performance and processing economics.

Comprehensive quality assurance validates induction hardening effectiveness through multiple testing approaches verifying mechanical properties, microstructure, and dimensional accuracy. Systematic inspection programs ensure consistent gear quality supporting long-term reliability.

Surface hardness measurement employs Rockwell C scale testing verifying achievement of specified minimum values. Typical gear tooth surface hardness ranges from 58-64 HRC depending on material and application requirements. Multiple test locations across tooth profiles confirm uniform hardening.

Case depth determination utilizes microhardness traverse testing measuring hardness at incremental depths from surfaces into cores. Effective case depth defines the distance to 50 HRC hardness representing the transition from hardened case to softer core. Specifications typically require case depths between 0.5-3.0 mm for gear teeth.

Core hardness verification ensures sufficient ductility and toughness in gear body regions. Core hardness typically ranges from 25-40 HRC providing impact resistance and fatigue strength while maintaining machinability for post-hardening operations if required.

Microstructure analysis through optical microscopy confirms proper martensitic transformation without undesirable constituents. Metallographic preparation involves sectioning, mounting, polishing, and etching revealing grain structure, phase distribution, and hardening depth.

Grain size measurement documents fine grain maintenance throughout hardening processes. ASTM grain size standards enable quantitative comparison with specifications. Rapid induction heating typically produces ASTM 8-10 grain sizes superior to furnace processing.

Retained austenite quantification through X-ray diffraction identifies untransformed austenite fractions. Excessive retained austenite reduces as-quenched hardness and dimensional stability. Tempering transforms retained austenite improving property consistency.

Tooth geometry verification employs coordinate measuring machines and gear analyzers confirming hardening preserves critical dimensions within tolerances. Profile, lead, pitch, and runout measurements detect distortion requiring correction or causing rejection.

Distortion pattern analysis identifies systematic dimensional changes enabling process adjustments minimizing warping. Understanding distortion modes guides fixture design, quench optimization, and machining allowance determination.

Statistical process control tracks dimensional data revealing process capability and trend development. Control charting identifies process drift enabling preventive adjustments before producing out-of-specification gears.

Magnetic particle inspection detects surface and near-surface cracks potentially developed during quenching. Fluorescent magnetic particles reveal crack indications invisible to visual inspection preventing defective gear shipment.

Ultrasonic testing identifies internal discontinuities including quench cracks and original material defects. Automated scanning systems inspect production volumes efficiently providing documented verification.

Eddy current testing evaluates case depth non-destructively through electromagnetic property measurements. Calibration against metallographic standards enables rapid inline screening though accuracy limitations restrict application to rough sorting.

Understanding testing methodologies differences between various inspection approaches optimizes quality assurance programs.

Different industries and applications demand customized induction hardening approaches addressing unique performance requirements, production volumes, and economic constraints. Modern induction technology adapts to diverse gear manufacturing needs.

High-volume production requirements drive automotive gear hardening system design emphasizing throughput, automation, and consistency. Spin hardening machines process gears in 5-15 second cycles supporting daily production exceeding thousands of units.

Tight tolerance maintenance proves critical for transmission gears where dimensional accuracy directly affects noise, efficiency, and durability. Minimal distortion from induction hardening eliminates expensive grinding operations reducing manufacturing costs.

Material optimization through induction hardening enables downsizing and weight reduction. Enhanced surface properties permit gear tooth size reduction without compromising strength supporting fuel efficiency and emissions objectives.

Variable loading conditions characterize industrial applications requiring balanced property distributions. Hardened surfaces resist wear while ductile cores absorb shock loads preventing brittle fracture during overload or impact events.

Repair and remanufacturing capabilities enable economical component life extension through selective re-hardening of worn surfaces. Localized induction heating treats damaged zones without affecting entire gear bodies preserving dimensional accuracy.

Large gear capabilities address heavy machinery requirements including mining equipment, steel mills, and cement plants. Scanning induction systems harden gears exceeding several meters diameter impossible to treat through conventional methods.

Extreme size challenges face wind turbine gear hardening with slewing rings exceeding 5 meters diameter. Custom scanning equipment progressively hardens gear teeth maintaining tight case depth control despite massive dimensions.

Harsh environment resistance demands superior surface properties withstanding corrosive offshore conditions and temperature extremes. Induction hardening produces fine-grained martensitic cases exhibiting excellent corrosion fatigue resistance.

Field installation support enables on-site hardening for components too large for transportation or requiring in-place refurbishment. Portable induction equipment travels to wind farms performing maintenance without turbine removal.

Critical component reliability necessitates rigorous process control and documentation. Aerospace gear hardening employs certified procedures, validated equipment, and complete traceability meeting stringent qualification requirements.

Exotic material processing includes precipitation-hardening stainless steels and high-temperature alloys demanding specialized induction hardening techniques. Process development addresses unique transformation kinetics and property requirements.

Precision requirements for aerospace gears exceed commercial standards necessitating advanced fixturing, distortion compensation, and inspection. Coordinate measuring equipment verifies sub-micron dimensional control following hardening.

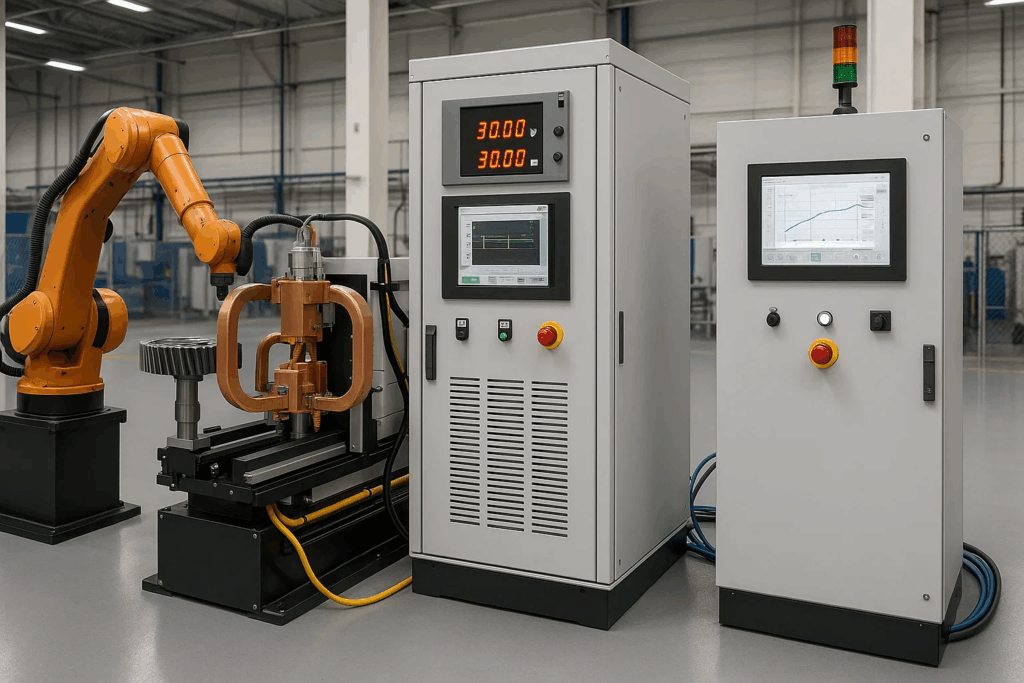

Successful induction gear hardening implementation requires careful equipment selection matching process requirements, production volumes, and available resources. Modern systems integrate multiple technologies delivering turnkey hardening solutions.

Solid-state generators provide precise power control with rapid response times enabling sophisticated heating profiles. Modern IGBT and MOSFET inverters deliver 5-1000 kW output at frequencies from 1 kHz to 500 kHz with excellent efficiency.

Frequency range capabilities must match anticipated gear size range and case depth requirements. Single-frequency systems suit dedicated applications while multi-frequency units provide flexibility for diverse product mixes.

Power level determination considers gear mass, required heating rate, and desired cycle time. Oversized generators enable future production increases while undersized units limit throughput and may produce inadequate heating uniformity.

Custom inductor engineering adapts electromagnetic field distribution to specific gear geometries optimizing heating patterns. Electromagnetic simulation software predicts heating uniformity guiding design iterations before expensive fabrication.

Coil construction materials emphasize high electrical conductivity and mechanical durability. Copper tubing with internal water cooling maintains coil temperatures preventing degradation and ensuring long service life.

Maintenance and replacement considerations influence coil design complexity and documentation. Modular construction enables field repair while comprehensive drawings support fabrication of replacement coils minimizing downtime.

Selecting appropriate induction heating equipment for steel applications ensures optimal performance and longevity.

Material handling systems including robotics, pick-and-place mechanisms, and conveyor integration enable unmanned operation supporting lights-out manufacturing. Automated loading reduces cycle times while improving safety eliminating operator exposure to heated components.

Process monitoring integration connects induction equipment with manufacturing execution systems providing real-time production visibility. Data logging supports quality documentation and statistical process control initiatives.

Inline processing capability embeds induction hardening within machining cells enabling complete gear manufacturing in single-piece flow. Elimination of batch processing and work-in-process inventory reduces lead times and carrying costs.

Electromagnetic shielding prevents personnel exposure to alternating magnetic fields meeting occupational exposure limits. Proper shielding design balances field containment against equipment access requirements and space constraints.

Thermal protection includes guarding preventing operator contact with heated workpieces and quench media splash shields. Interlocked access doors ensure equipment de-energization before operator entry into hazardous zones.

Emergency systems provide immediate power shutdown and equipment safing capabilities. Properly designed emergency stops, power disconnects, and fire suppression systems protect personnel and facilities.

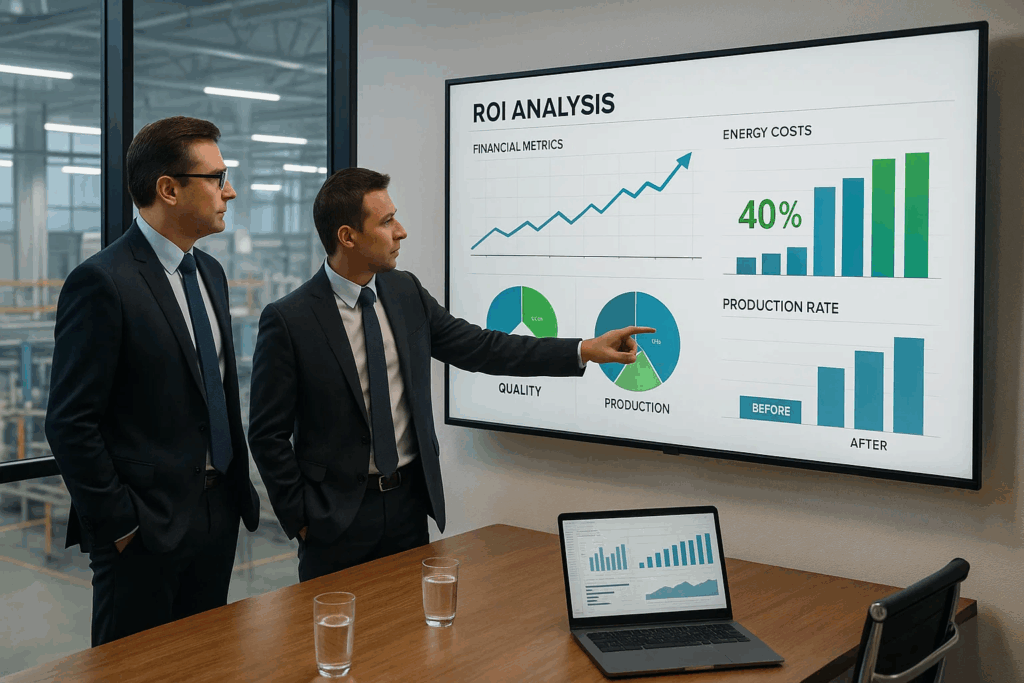

Induction gear hardening delivers compelling economic advantages through operational improvements, quality enhancements, and reduced resource consumption. Comprehensive financial analysis demonstrates rapid payback supporting capital investment justification.

Energy reduction compared to furnace operations achieves 40-60% utility expense decrease. Electromagnetic heating efficiency and elimination of standby losses yield immediate bottom-line improvements. Typical energy savings range from thousands to hundreds of thousands annually depending on production volume.

Floor space optimization results from compact induction equipment footprints compared to extensive furnace installations. Space savings enable facility expansion accommodating production growth without building additions.

Labor efficiency improves through automation reducing direct labor requirements while enabling personnel reallocation to higher-value activities. Typical labor savings range from 0.5-2.0 FTE per system depending on previous process methods.

Scrap reduction through improved process control and distortion minimization eliminates expensive gear rejection. Typical scrap rate improvements range from 2-5% representing substantial material and machining cost recovery.

Rework elimination follows from consistent first-time quality achievement. Reduction or elimination of straightening, re-grinding, and dimensional correction operations directly improves profitability while accelerating delivery.

Warranty claim reduction results from enhanced gear durability and reliability. Improved hardness uniformity, fine grain structures, and optimized property distributions extend service life reducing field failures and associated costs.

Production flexibility enables rapid changeover between gear types supporting mixed-model manufacturing and small batch economics. Quick coil changes and programmable parameters accommodate diverse product portfolios.

Capacity expansion without proportional capital investment supports growth. Cycle time reduction effectively multiplies equipment capacity enabling production increases within existing installations.

Technology leadership demonstrates commitment to advanced manufacturing attracting customers valuing quality and innovation. Induction hardening capability differentiates suppliers in competitive markets supporting premium positioning.

Understanding industrial induction heating applications demonstrates technology value across manufacturing sectors.

Induction hardening heats gears in seconds using electromagnetic fields, creating selective surface hardening while maintaining ductile cores. Furnace hardening takes hours and heats entire gears uniformly. Induction offers faster cycles (3-15 seconds vs 30-90 minutes), 70-90% energy efficiency versus 15-40% for furnaces, minimal distortion, and enables inline production integration.

Typical case depths range from 0.5-3.0mm measured to 50 HRC hardness. Higher frequencies (100-500 kHz) produce shallow cases (0.5-1.5mm) for surface wear, while lower frequencies (1-10 kHz) create deeper penetration (2-5mm) for heavy loads. Through-hardening is possible for smaller gears with appropriate frequency and power settings.

Medium carbon steels (0.40-0.60% C) like SAE 1045, 1050, 4140, and 4340 work best. Carbon content of 0.45-0.55% offers optimal balance of hardness and toughness. Alloy steels with chromium and molybdenum enhance hardenability and reduce crack susceptibility while providing excellent wear resistance.

Yes, induction adapts to gears from 10mm to over 5 meters diameter. Small gears use spin or tooth-by-tooth methods, large gears employ scanning techniques. Spur, helical, bevel, and internal gears all process successfully with custom coil designs for automotive, industrial, and wind turbine applications.

Induction reduces distortion by 60-80% versus furnace processing. Localized heating and rapid cycles minimize warping. Many gears maintain dimensions within ±0.05mm tolerances without post-hardening straightening or grinding, eliminating expensive secondary operations while improving gear quality and performance.

Induction heating revolutionizes gear heat treatment delivering superior metallurgical results, dramatic throughput improvements, and compelling economic benefits. The technology transforms traditional batch processing into rapid inline operations while enhancing quality and reducing environmental impact.

Successful implementation requires systematic approaches balancing technical requirements against economic constraints. Organizations investing in proper equipment selection, process development, and personnel training realize substantial competitive advantages through improved product performance and manufacturing efficiency.

The technology continues advancing through digitalization, automation, and process innovations. Forward-thinking manufacturers embracing induction gear hardening position themselves for sustained success in increasingly demanding markets requiring exceptional quality, flexibility, and sustainability.

Ready to transform your gear manufacturing operations? Contact our induction heating specialists to discuss customized solutions optimized for your specific application requirements and production objectives.