Investing in the wrong induction heater for steel heat treatment can cost your operation thousands in wasted energy, inconsistent hardening patterns, and rejected components. Without proper frequency selection, power calibration, or coil design, you risk surface defects, inadequate hardness depth, and production delays that impact your bottom line.

These challenges multiply when you’re processing critical components—automotive gears, aerospace shafts, or industrial tooling—where precision isn’t optional. The consequences? Premature component failure, warranty claims, and damaged reputation.

Fortunately, selecting the right induction heater transforms these risks into competitive advantages. This comprehensive guide reveals the essential factors, technical specifications, and expert insights you need to choose an induction heating system that delivers consistent, high-quality steel heat treatment results while optimizing your operational efficiency.

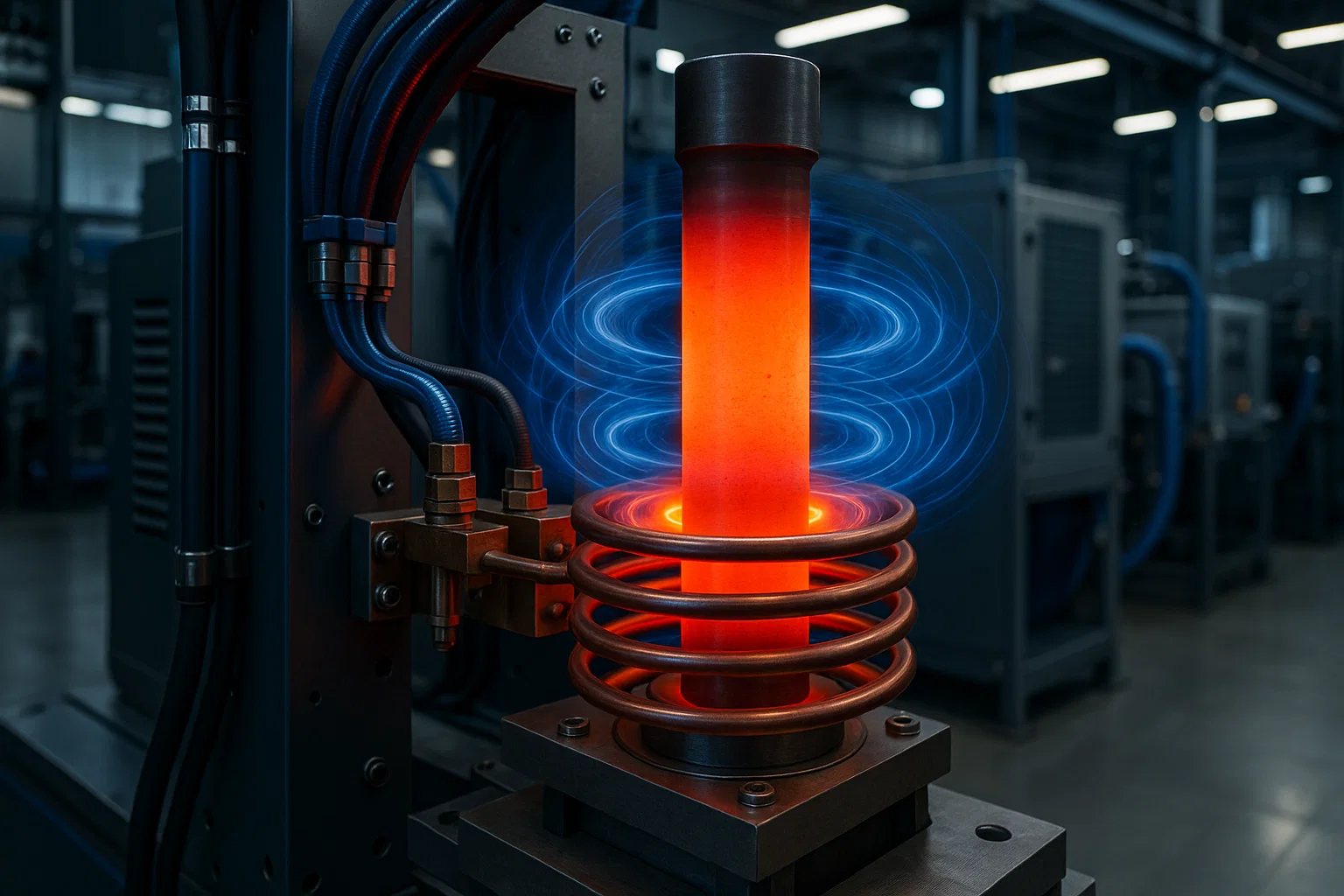

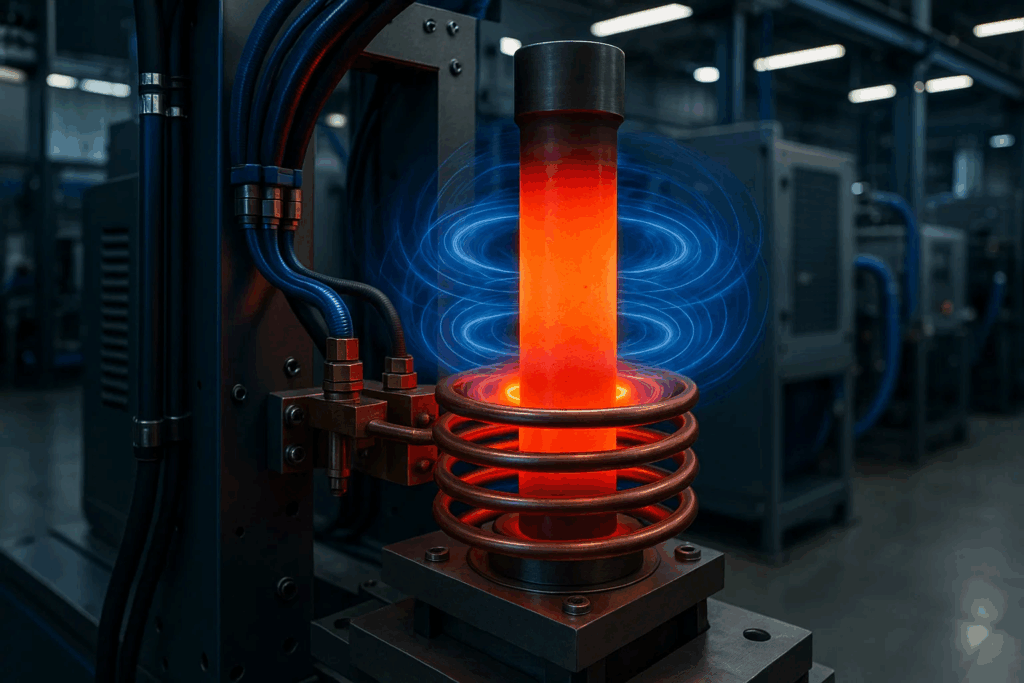

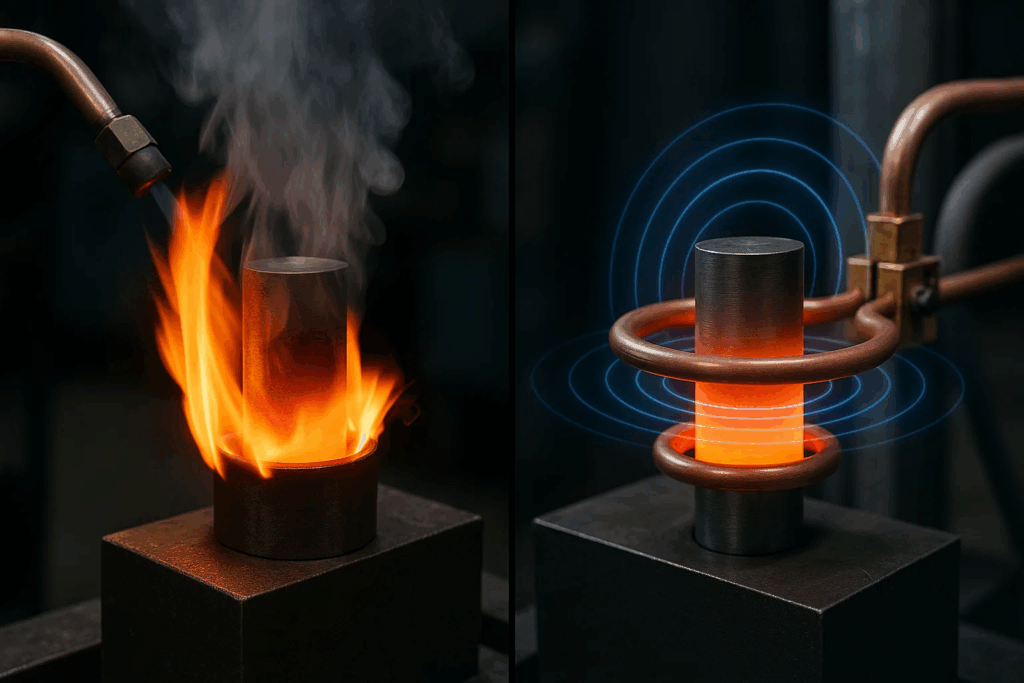

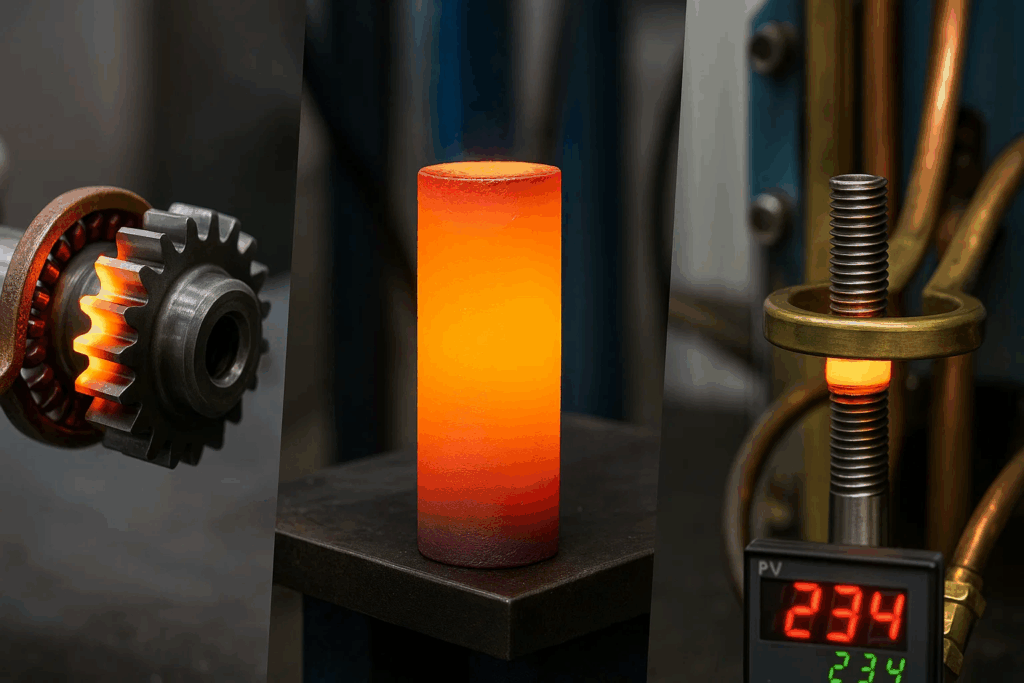

Induction heating revolutionizes steel heat treatment through electromagnetic induction principles. When an alternating current flows through a copper coil, it generates a powerful electromagnetic field that induces eddy currents within conductive steel components. These currents, combined with the material’s electrical resistance and magnetic properties, produce localized heat through Joule heating and hysteresis losses.

This non-contact heating method offers remarkable precision, allowing manufacturers to achieve specific heating patterns that follow the applied magnetic field closely while minimizing thermal distortion and damage.

Understanding how electromagnetic induction works forms the foundation of effective heat treatment. The process delivers heat directly within the steel workpiece rather than through external conduction, enabling rapid temperature changes and tight process control.

The heating depth and intensity depend on several interconnected factors: the electromagnetic field’s frequency, coil placement relative to the workpiece, power density (kVA output), and the steel’s intrinsic properties including permeability, resistivity, and ferromagnetic characteristics.

Compared to conventional methods like salt baths or vacuum ovens, induction heating provides superior energy efficiency, precision, speed, and enhanced worker safety by eliminating open flames and hot elements.

Key advantages include:

Choosing the optimal induction heater requires careful evaluation of multiple technical parameters that directly impact treatment quality and operational efficiency.

Not all steel grades respond identically to induction heating. Carbon content plays a decisive role—steels with 0.4% to 0.6% carbon content typically deliver optimal hardening results. Lower carbon content (below 0.3%) generally proves unsuitable for effective induction hardening.

Higher carbon content leads to greater surface hardness after heat treatment but increases the risk of cracking or distortion, while alloying elements like manganese increase hardening depth and chromium improves corrosion resistance.

Compatible steel grades for induction heat treatment include:

Magnetic materials like ferrous steels heat more efficiently due to hysteresis losses below the Curie point, while high-resistivity metals like steel heat faster than low-resistivity materials such as copper or aluminum.

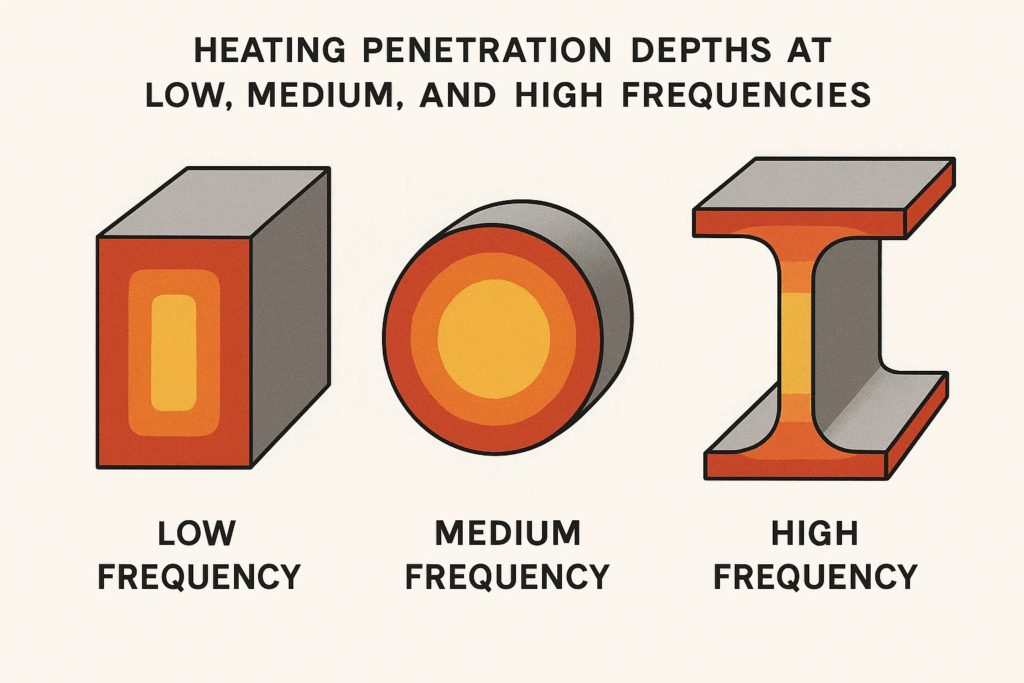

The relationship between operating frequency and current penetration depth is inversely proportional—lower frequencies produce deeper case hardening, while higher frequencies concentrate heat at the surface.

Recommended frequency ranges for steel applications:

The frequency selection also influences electromagnetic end effects and edge effects, which become critical when processing gear teeth, splines, and complex geometries. Proper induction heating coil design works synergistically with frequency selection to achieve uniform heating patterns.

The power supply’s output determines the heating speed, with part mass, required temperature rise, and heat losses from convection and conduction all factoring into power calculations.

Power requirements vary based on:

Undersized systems extend cycle times and reduce throughput, while oversized systems inflate capital costs without proportional benefits. For best induction heater performance in industrial applications, match power output to your specific production requirements.

The induction coil represents the critical interface between the power supply and workpiece. Optimal coil design considers the component’s geometry, required heating pattern, and process workflow.

Common coil configurations include:

The coil’s copper conductor dimensions, turn spacing, and cooling system design directly affect efficiency and service life. Water-cooled copper coils typically offer the best combination of electrical conductivity and thermal management for demanding steel treatment applications.

Different steel heat treatment processes demand tailored induction heating approaches. Understanding these application-specific requirements ensures optimal equipment selection.

Induction hardening processes create a hardened surface layer while maintaining core toughness—ideal for components requiring wear resistance and impact strength.

Surface hardening produces localized hardening where wear resistance is needed while retaining the original structure’s toughness elsewhere, with depth control achieved through frequency, power density, and interaction time selection.

Typical case depths range from 0.5mm to 7mm depending on application requirements. Automotive transmission gears might require 2-3mm depth, while bearing races may need only 1-1.5mm hardened layer.

Induction forging applications require heating the entire component to forging temperature uniformly. Lower frequencies (1-10 kHz) ensure adequate penetration for thick sections.

The heating cycle must account for:

Post-hardening tempering reduces brittleness and relieves residual stresses. Induction tempering offers precise temperature control and reduced cycle times compared to furnace tempering.

Understanding materials suitable for induction hardening helps optimize tempering parameters to achieve the desired mechanical properties balance.

When comparing induction heating systems, several technical parameters merit careful scrutiny beyond basic power and frequency ratings.

Modern induction heaters utilize solid-state power supplies with IGBT (Insulated Gate Bipolar Transistor) technology. These advanced systems can generate frequencies exceeding 5 MHz with precise control and high efficiency.

Advanced systems offer:

High-efficiency induction heating with SiC-GaN semiconductors represents the cutting edge of power supply technology, offering improved efficiency and reduced energy consumption.

Effective cooling prevents coil overheating and ensures consistent performance. Water cooling systems must provide adequate flow rate and maintain appropriate temperature differentials.

Critical cooling parameters:

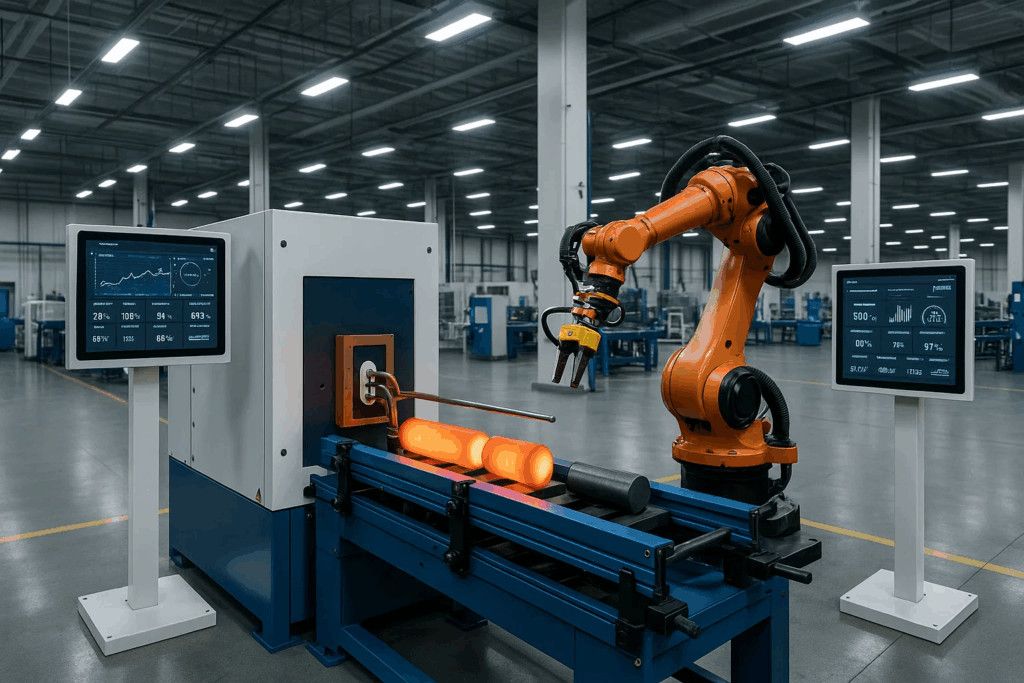

Smart induction heating systems incorporate advanced monitoring and control capabilities that enhance precision and efficiency.

Modern control systems feature:

Beyond technical specifications, practical operational factors significantly impact the long-term success of your induction heating investment.

Match equipment capacity to production demands. High-volume operations justify larger, more automated systems, while job shops benefit from flexible, operator-friendly designs.

Calculate required throughput:

Physical integration into existing production lines affects equipment selection:

Induction heating achieves up to 50% greater energy efficiency compared to alternative heating methods, resulting in substantial energy savings.

Calculate total cost of ownership:

Comparing induction heating vs resistance heating reveals significant long-term cost advantages for properly specified induction systems.

Different industries present unique heat treatment challenges that influence induction heater selection criteria.

Induction heating in the automotive industry demands high-volume processing with consistent quality for transmission components, axle shafts, steering parts, and CV joints.

Automotive applications typically require:

Aerospace components demand stringent quality documentation and precise metallurgical control. Heat treatment processes must meet rigorous specifications with complete traceability.

Critical aerospace considerations:

Industrial applications span a broad spectrum from agricultural equipment to heavy machinery, mining components to construction equipment.

Working principles of bearing induction heaters demonstrate specialized applications within general industrial manufacturing, where precision heating enables proper bearing installation and optimal fit.

The induction heater supplier’s capabilities and support infrastructure often prove as critical as equipment specifications.

Experienced suppliers offer invaluable application engineering support:

Comprehensive operator training ensures effective equipment utilization and reduces costly mistakes. Look for suppliers providing:

Long-term reliability depends on robust service support:

Ensuring consistent heat treatment quality requires robust validation and monitoring protocols.

Establish comprehensive quality control procedures:

Real-time monitoring prevents defects and ensures repeatability:

Quality systems demand comprehensive documentation:

The induction heating industry continues evolving with emerging technologies that enhance capability and efficiency.

New generation IGBT inverters enable instant and independent frequency adjustment from 5kHz to 60kHz and power up to 450kW in pre-programmed patterns during heating cycles, optimizing electromagnetic, thermal, and metallurgical conditions.

These systems overcome limitations of single-frequency equipment by:

Advanced finite element analysis (FEA) software enables virtual process development:

Smart induction heating technologies embrace digital transformation:

Selecting the optimal induction heater for steel heat treatment demands careful evaluation of multiple interconnected factors. Your decision should balance immediate application requirements with long-term operational goals and potential future needs.

Key takeaways for successful selection:

The right induction heating system transforms steel heat treatment from a potential bottleneck into a competitive advantage, delivering consistent quality, improved efficiency, and reduced operating costs. By applying the selection criteria outlined in this guide, you’ll be well-equipped to make an informed investment decision that serves your operation’s needs for years to come.

For applications requiring precise electrical testing of motor windings and transformers, explore complementary technologies like digital armature surge testers that ensure comprehensive quality assurance in electrical component manufacturing.

Ready to optimize your steel heat treatment process? Start by clearly defining your application requirements, then consult with experienced induction heating specialists who can provide laboratory testing and tailored system recommendations for your specific needs.

For 40mm diameter shafts requiring through-heating for forging, use 3-10 kHz. For surface hardening only, 10-30 kHz provides 2-4mm case depth, while 50-100 kHz delivers 1-2mm surface hardening.

Multi-frequency systems with adjustable power output offer flexibility for various applications. However, coil design typically remains application-specific, so quick-change coil systems work best for multi-product operations.

Coil life varies dramatically based on application severity, cooling system effectiveness, and power density. Well-designed coils in moderate-duty applications may last 6-12 months, while severe applications might require quarterly replacement.

No. Steel requires minimum 0.3-0.4% carbon content for effective hardening. Low-carbon steels, austenitic stainless steels, and some specialty alloys respond poorly to induction hardening.

Induction heating typically consumes 40-50% less energy than conventional furnace heating for equivalent results, with the exact savings depending on component size, cycle time, and specific application requirements.

About Vivid Metra Watt Global

Vivid Metra Watt Global specializes in advanced induction heating solutions and precision electrical testing equipment for industrial applications. Our comprehensive product portfolio includes state-of-the-art induction heaters, digital surge testers, and specialized testing instruments designed to meet the demanding requirements of modern manufacturing. With decades of combined expertise and commitment to innovation, we help industries worldwide achieve optimal performance, reliability, and efficiency in their thermal processing and quality assurance operations.