Motor failures due to undetected armature faults cost industries millions in downtime and repairs annually. Traditional testing methods often miss critical insulation weaknesses that lead to catastrophic motor failures. Digital armature surge testers provide comprehensive fault detection, preventing costly breakdowns and ensuring optimal motor performance.

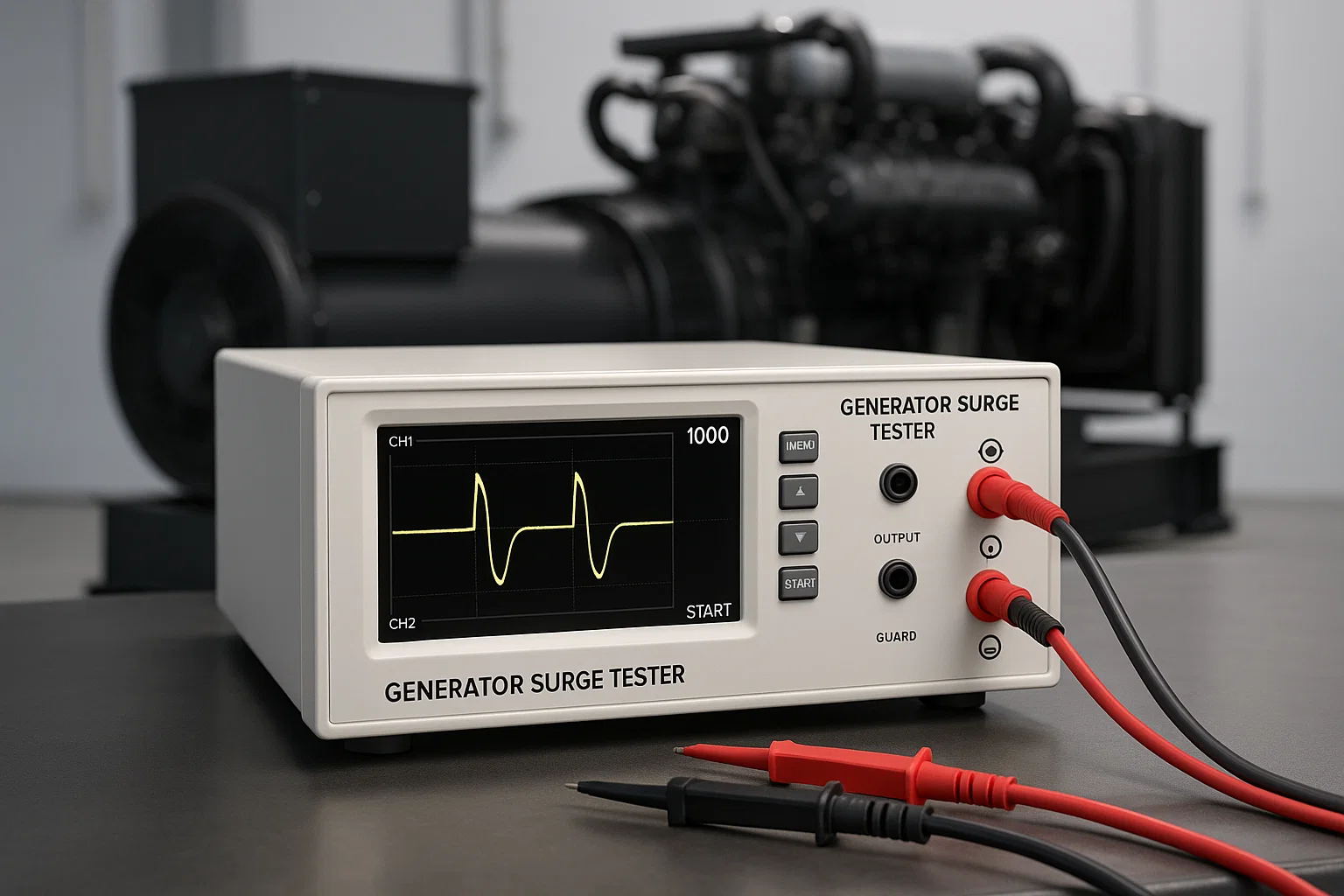

A digital armature surge tester is a sophisticated diagnostic instrument specifically designed to evaluate the electrical integrity of DC motor armatures and field coils. Unlike conventional testing methods, these advanced devices apply high-voltage pulses to detect insulation weaknesses, short circuits, and other faults that could compromise motor performance.

These precision instruments have revolutionized motor testing by providing accurate, reliable, and comprehensive analysis capabilities. The Digital Armature Surge Tester serves as a cost-effective partner for assessing the quality of small to medium range DC armatures, equipped with specialized bar-to-bar test features.

Digital armature surge testers address critical challenges in motor maintenance and quality assurance. They detect faults invisible to routine inspections, including:

The importance of these testers extends beyond simple fault detection. They provide predictive maintenance capabilities that help organizations transition from reactive to proactive maintenance strategies.

The operational principle of digital armature surge testers centers on surge testing methodology. The instrument takes normal 115 or 220V AC power and transforms it to the higher voltage required for the surge test. The higher voltage is rectified into a DC voltage which charges up a large discharge capacitor.

Step 1: High-Voltage Pulse Generation The tester generates controlled high-voltage pulses ranging from 1kV to 6kV, depending on the specific model and application requirements.

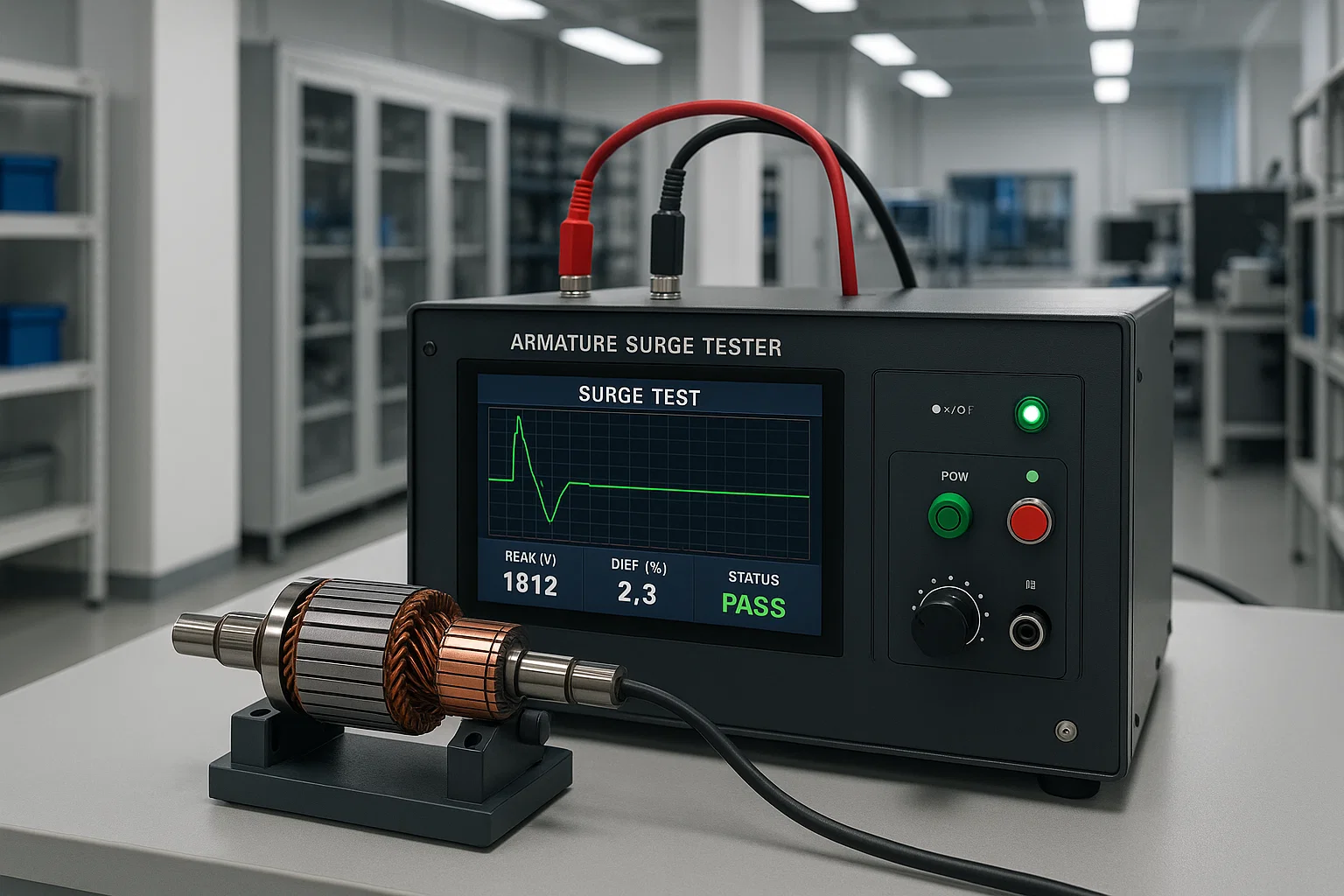

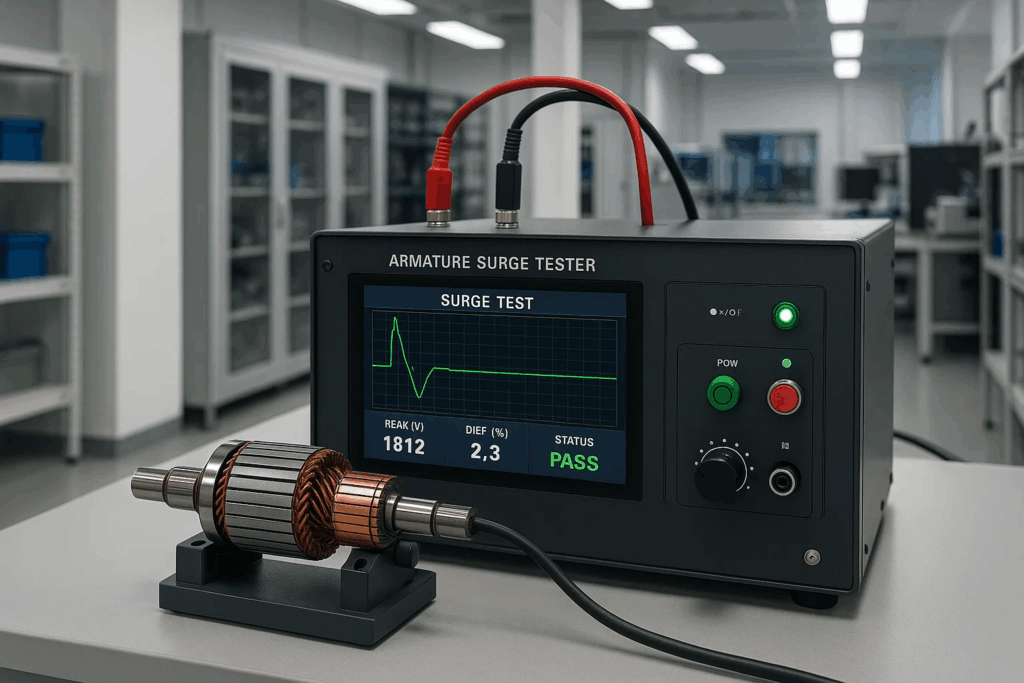

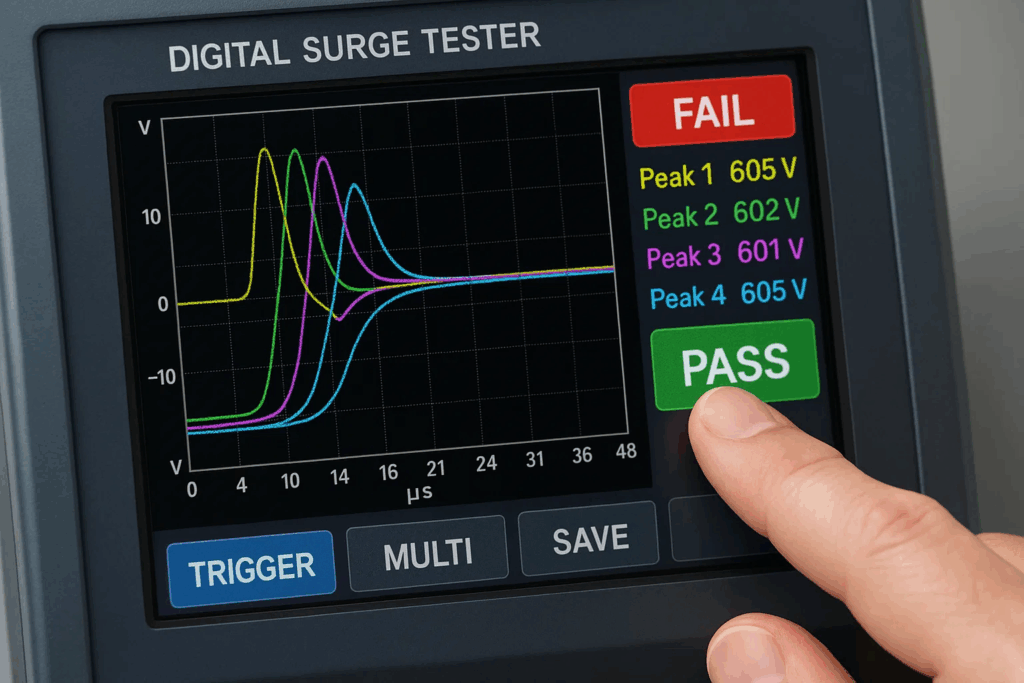

Step 2: Waveform Analysis The surge creates an oscillating waveform, which reflects the winding’s resistance and insulation condition. By observing these waveform patterns, technicians can assess whether the armature is functioning optimally.

Step 3: Pattern Recognition Advanced digital processing algorithms analyze waveform patterns, comparing them against reference standards to identify anomalies.

Step 4: Results Interpretation The system provides clear pass/fail determinations with detailed analysis reports.

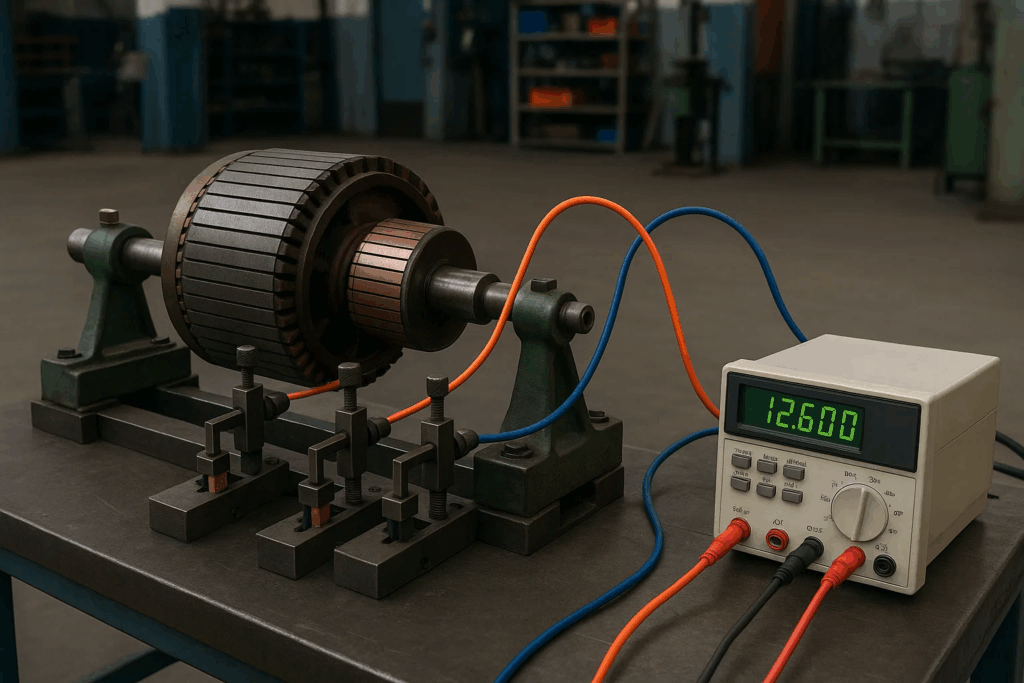

The Bar-To-Bar Test is provided to test the Low impedance of the Series wound Armatures and Field coils of DC Traction Motors. This specialized testing method involves:

Modern digital armature surge testers incorporate sophisticated technology to deliver precise, reliable results:

Central to this tester is an embedded industrial PC, boasting an 8-inch touch screen display that offers an interactive and user-friendly interface. Key specifications include:

The evolution from analog to digital technology has transformed armature testing capabilities:

Enhanced Precision Digital surge testers offer enhanced precision and more advanced features compared to analog ones, making them easier to use in complex testing environments.

Waveform Storage and Analysis The digital design is based on the latest technique of digitizing the analog waveforms generated during the surge test of wound components. In conventional surge comparison testers, the waveform of the test coil has to be compared with the waveform of the reference coil, but this shortcoming is eliminated in digital design.

Advanced Data Management

Reference Coil Degradation Traditional analog systems suffer from reference coil deterioration, making long-term comparisons unreliable.

Limited Data Retention Analog systems lack comprehensive data storage and analysis capabilities.

Manual Interpretation Requirements Analog displays require experienced operators for accurate interpretation.

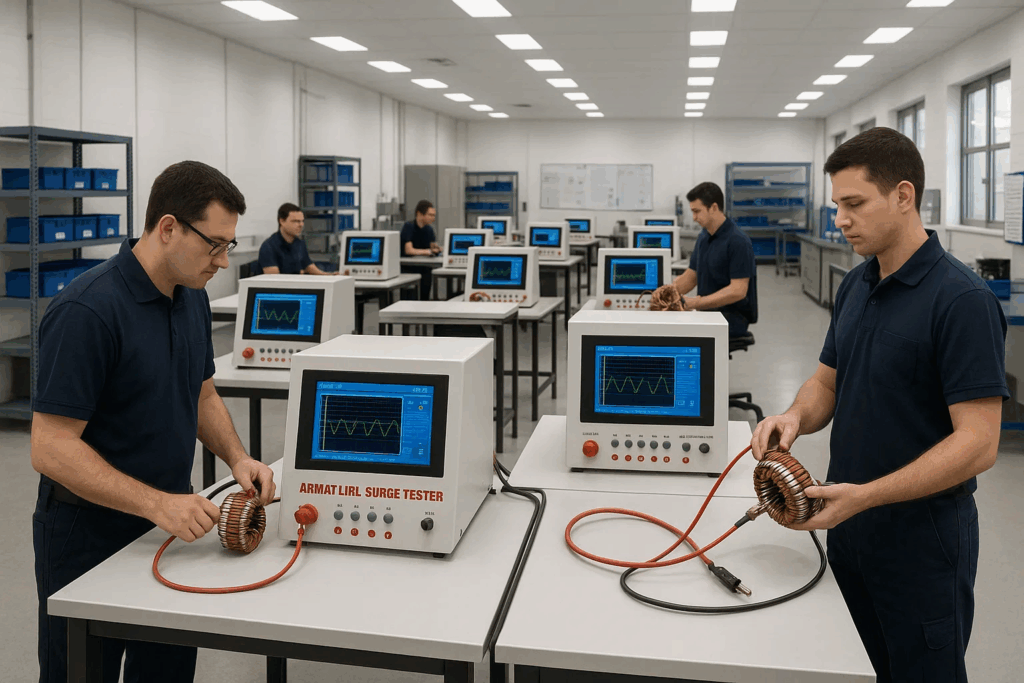

Digital armature surge testers serve diverse industrial applications:

Electronic parts abound in modern cars, including motors, wiring harnesses, and ignition coils. Digital surge testers are useful in testing these components at high voltages to ensure they won’t break down when you need them most.

Early Fault Detection The important advantage surge testing offers when applied to armature is the ability to locate high resistance carbon shorts. These can be major problems and cannot be detected by the low voltage tests normally done.

Cost Reduction

Enhanced Safety

Improved Efficiency

Quality Assurance

Technical Excellence

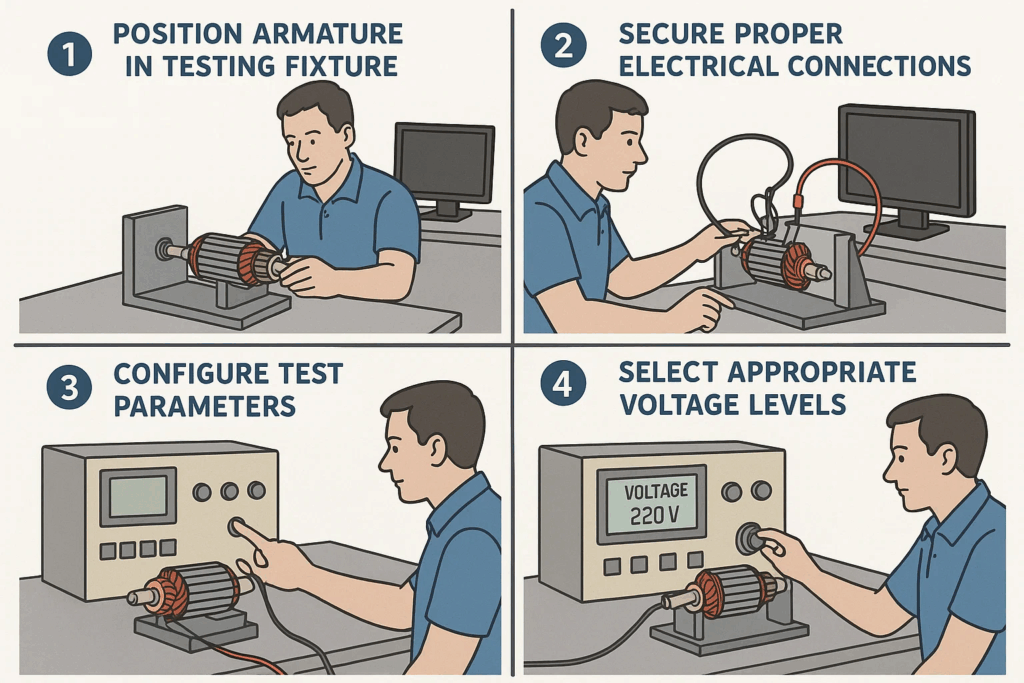

Safety Protocols Before beginning, follow these essential safety guidelines: Wear protective gear such as gloves and goggles. Make sure your workspace is clear and grounded properly.

Equipment Verification

Initial Setup

Test Execution Start by applying a surge of low voltage. Observe the waveform on the display. Increase the voltage in gradual increments while continuing to monitor the waveform.

Results Analysis

Regular Calibration Maintain testing accuracy through scheduled calibration procedures following manufacturer specifications.

Proper Documentation Maintain comprehensive test records including:

Trending Analysis Establish baseline measurements and track changes over time to identify developing issues.

Turn-to-Turn Shorts The surge test is the only test that finds turn-to-turn insulation weaknesses in motor windings. These weaknesses cannot be found with insulation resistance/megohm, low-voltage measurements or high-voltage high-potential (hipot) tests.

Ground Faults Detection of insulation breakdown between windings and armature core.

Inter-Coil Shorts Identification of faults between adjacent coils or coil groups.

High Resistance Joints

Wrong Connections

Normal Patterns A consistent waveform generally indicates a healthy armature.

Fault Indicators

Voltage Range Requirements

Testing Capabilities Consider the specific testing requirements:

Ease of Use

Data Management

Initial Investment Balance initial cost against long-term benefits and return on investment.

Operating Costs Consider ongoing maintenance, calibration, and training expenses.

Total Cost of Ownership Evaluate complete lifecycle costs including support and updates.

Daily Checks

Weekly Maintenance

Monthly Procedures

Frequency Standards Follow manufacturer recommendations for calibration intervals, typically annually or based on usage levels.

Traceable Standards Use NIST-traceable calibration standards to ensure measurement accuracy and regulatory compliance.

Documentation Maintain complete calibration records including:

Display Problems

Measurement Irregularities

For comprehensive troubleshooting guidance, explore our detailed article on troubleshooting common surge tester errors.

Modern digital armature surge testers increasingly incorporate AI-powered analysis capabilities:

Pattern Recognition

Data Analytics

Network Integration

Integration Standards

Digital armature surge testers represent a critical advancement in motor testing technology, providing unparalleled fault detection capabilities that traditional methods cannot match. These sophisticated instruments enable organizations to transition from reactive maintenance strategies to proactive reliability programs, significantly reducing costs and improving operational efficiency.

Key Takeaways:

The evolution toward digital technology continues to transform armature testing, with AI integration, enhanced connectivity, and advanced analytics driving future capabilities. Organizations investing in modern digital armature surge testers position themselves for improved motor reliability, reduced maintenance costs, and enhanced operational performance.

For specialized applications in motor testing, consider exploring our comprehensive guides on how to test motor windings and surge testing enhances motor reliability and efficiency. Additionally, understand the differences between testing methods with our comparison of surge tester vs hipot tester.

About Vivid Metrawatt Global

Vivid Metrawatt Global specializes in advanced electrical testing equipment, including state-of-the-art digital armature surge testers. Our comprehensive range of testing solutions ensures motor reliability and performance across diverse industrial applications. Contact our technical experts to discuss your specific testing requirements and discover how our digital armature surge testers can enhance your maintenance programs.