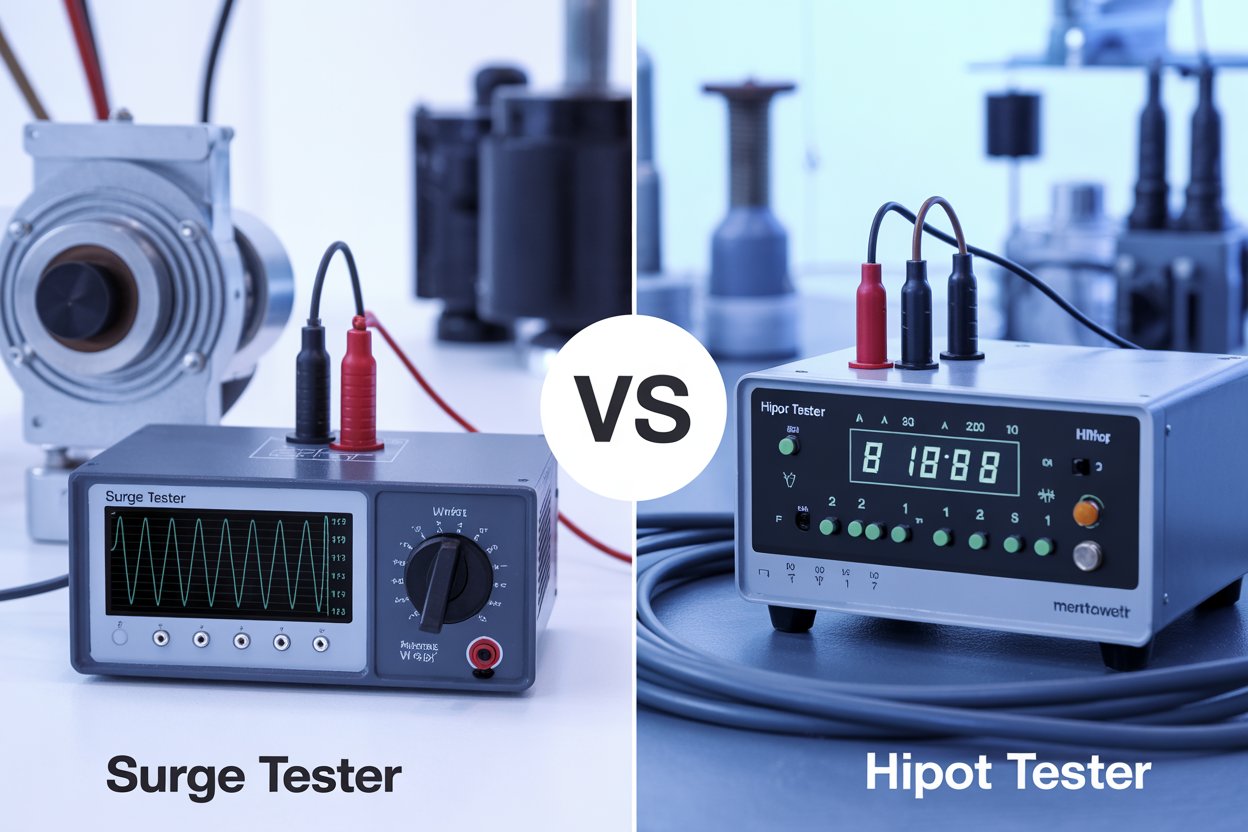

Are you struggling to choose between a surge tester and a HiPot tester for your electrical testing needs? You’re not alone. Making the wrong choice can lead to inadequate testing, safety risks, and costly equipment failures. In today’s industrial environment where electrical reliability is paramount, understanding these critical testing tools is essential for maintenance professionals and electrical engineers.

This comprehensive guide will demystify surge testers and HiPot testers, explain their fundamental differences, and help you determine which one is right for your specific application.

A surge tester, also known as an impulse winding tester, is a specialized diagnostic device designed to evaluate the insulation integrity between turns of a winding in electrical equipment. It works by applying a high-voltage pulse (surge) to the windings and analyzing the resulting waveform response.

Surge testers operate on a fundamental principle: when a rapid high-voltage pulse is applied to windings, it creates a voltage differential between adjacent turns. This test reveals problems that other insulation tests might miss, such as:

The surge tester displays the resulting waveform on a screen, allowing technicians to compare waveforms between phases or against a reference standard. Deviations in the waveform pattern indicate potential insulation weaknesses or failures.

Modern surge testers come in various configurations:

A HiPot (High Potential) tester is a device that tests the electrical insulation in devices and equipment by applying a voltage significantly higher than the operating voltage to verify that the insulation can withstand voltage spikes without breaking down.

HiPot testers apply a high voltage between two points and measure the resulting current flow. The test is designed to:

Unlike surge testers, which focus on turn-to-turn insulation, HiPot testers primarily evaluate the insulation between conductive parts and ground or between separate conductive components.

HiPot testers typically fall into two main categories:

The fundamental difference between these two testers lies in what they’re designed to detect:

The measurement approach differs significantly:

Each tester excels at detecting specific types of faults:

| Surge Tester | HiPot Tester |

|---|---|

| Turn-to-turn insulation faults | Ground insulation faults |

| Winding symmetry issues | Leakage current problems |

| Phase imbalances | Conductor-to-conductor insulation |

| Shorted turns | Breakdown voltage thresholds |

While there is some overlap, each tester has optimal application areas:

Surge Testers are ideal for:

HiPot Testers are preferred for:

Surge testing is essential for electric motors and generators because turn-to-turn insulation failures are often the first point of breakdown in these devices. A digital surge tester can detect these failures before they lead to catastrophic equipment damage.

Incorporating surge testing into regular maintenance schedules allows for:

Manufacturers use surge testers to:

HiPot testing is often mandated for:

HiPot testers excel at:

Before energizing new equipment, HiPot testing ensures:

For comprehensive insulation evaluation, using both surge and HiPot testing provides a complete picture of equipment health. Modern testing platforms like Vivid Metrawatt’s combined surge and HiPot testers offer advantages such as:

Advanced testers offer programmed test sequences that:

Consider these key factors when selecting between surge and HiPot testers:

Different industries prioritize different aspects of electrical testing:

Manufacturing:

Maintenance Services:

Utilities:

Vivid Metrawatt Global stands as an industry leader in electrical testing equipment, offering a comprehensive range of both surge testers and HiPot testers to meet diverse industry needs. Our cutting-edge technology combines precision, reliability, and user-friendly interfaces to ensure accurate results and equipment protection.

Our digital surge testers feature:

For those seeking combined testing solutions, our integrated surge and HiPot testing platforms deliver unparalleled versatility and efficiency, backed by our dedicated customer support team.

For critical motors in continuous operation, quarterly surge testing is recommended. For less critical applications, semi-annual or annual testing may be sufficient as part of a preventive maintenance program.

When performed correctly, surge testing will not damage healthy equipment. Modern surge testers are designed with safety features to prevent excessive voltage application. However, if insulation is already severely compromised, any high-voltage test might accelerate the failure.

AC HiPot testing applies alternating current voltage and can detect both resistive and capacitive leakage current issues. DC HiPot testing applies direct current and primarily measures resistive leakage. DC testing is often preferred for field testing as it requires less power and puts less stress on healthy insulation.

Yes, manufacturers like Vivid Metrawatt offer combined testing platforms that incorporate both surge and HiPot testing capabilities in a single unit, providing comprehensive insulation analysis with maximum efficiency.

Operators should have training in electrical safety, understanding of insulation systems, and specific training on the test equipment being used. Many manufacturers offer training programs for their testing equipment.

The choice between surge testers and HiPot testers isn’t about which is better—it’s about which is right for your specific application. Understanding the fundamental differences between these two testing methodologies is crucial for implementing effective electrical maintenance and quality control programs.

For comprehensive insulation system evaluation, many facilities benefit from having both capabilities available, either as separate units or through combined testing platforms. By selecting the appropriate testing strategy, you can enhance equipment reliability, improve safety, and reduce costly downtime.

Need expert guidance on selecting the right testing equipment for your application? Contact Vivid Metrawatt’s team of specialists for personalized recommendations based on your specific industry and testing requirements.