Introduction

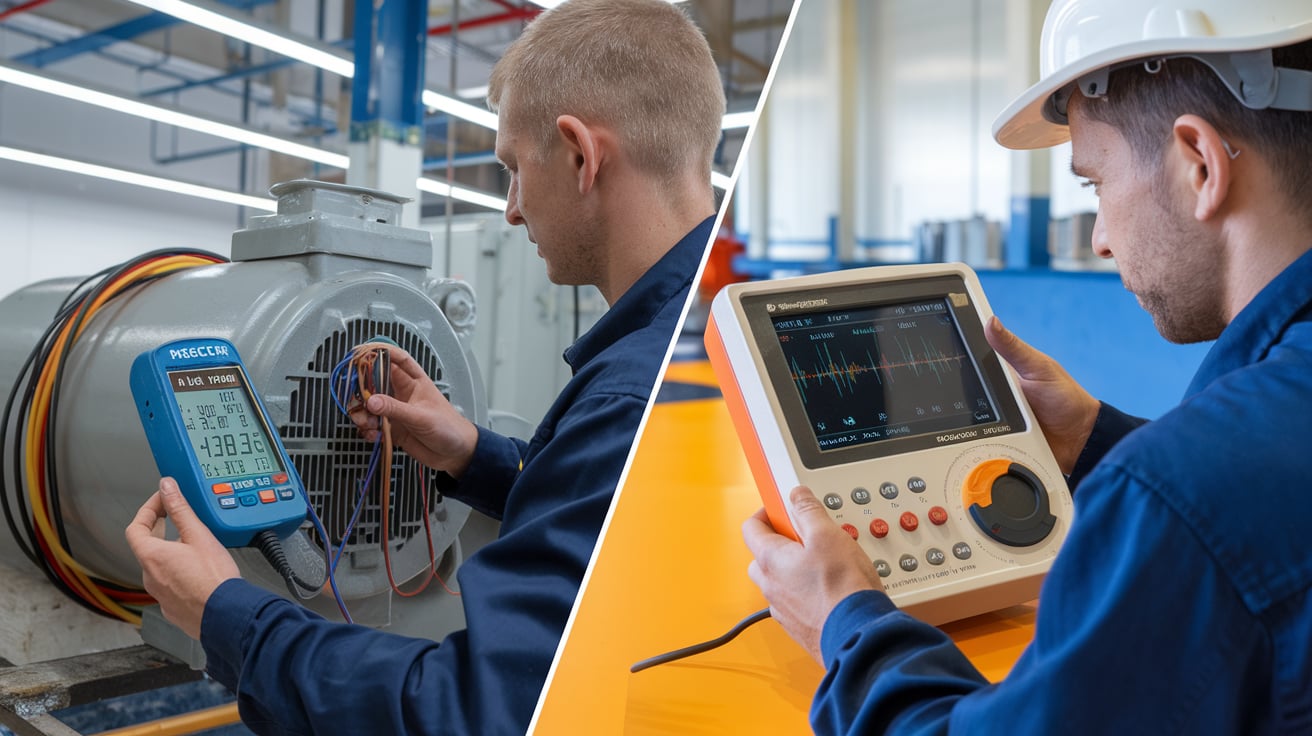

Electrical maintenance professionals often face critical decisions when selecting the appropriate testing method for motor and transformer windings. Both Megger testing and surge testing are vital diagnostic tools, but they serve fundamentally different purposes in your maintenance program. When incorrectly applied or improperly substituted for one another, these tests can lead to missed faults, unexpected equipment failures, and costly downtime. Understanding the precise differences between these testing methodologies ensures comprehensive winding assessment and maximizes equipment reliability.

Basic Purpose and Function

Megger Testing (Insulation Resistance Testing)

Megger testing, named after the popular brand of insulation testers, focuses on measuring the resistance between winding conductors and ground. This test:

- Evaluates the quality of ground wall insulation

- Measures electrical resistance in megohms

- Applies steady DC voltage between windings and ground

- Monitors current leakage through insulation

- Assesses insulation’s ability to prevent current flow to ground

Surge Testing

Surge testing, also known as impulse testing, examines the insulation integrity between adjacent turns within the same winding. This test:

- Evaluates turn-to-turn insulation quality

- Applies rapid high-voltage pulses to windings

- Creates voltage stress between adjacent turns

- Generates comparative waveforms for analysis

- Reveals subtle insulation weaknesses between turns

The fundamental difference lies in their focus: Megger testing examines ground insulation, while surge testing evaluates turn-to-turn insulation integrity.

What Each Test Detects

Megger Testing Detects

Megger testing is highly effective at identifying:

- Ground wall insulation deterioration

- Moisture contamination in windings

- Dirt and conductive contamination

- Phase-to-ground faults

- Tracking paths to ground

- General insulation degradation over time

- Suitability for service regarding ground insulation

Limitation: Megger testing cannot detect turn-to-turn faults within the same winding, as these faults don’t involve the ground path.

Surge Testing Detects

Surge testing excels at identifying:

- Turn-to-turn insulation failures

- Coil-to-coil shorts

- Phase-to-phase insulation weaknesses

- Winding shorts

- Open circuits in windings

- Incorrect connections

- Unbalanced windings

- Early stages of insulation deterioration between turns

Limitation: While powerful for detecting internal winding faults, surge testing may not be as sensitive to ground insulation issues as dedicated ground insulation tests.

Testing Methodology Differences

Megger Testing Methodology

When performing a Megger test:

- The equipment is disconnected and safely isolated

- Test leads are connected between windings and ground

- DC voltage (typically 500V, 1000V, 2500V, or 5000V) is applied

- Current flow is measured after a specified time (60 seconds is standard)

- Resistance is calculated and compared to acceptable values

- Polarization index may be calculated (10-minute reading divided by 1-minute reading)

Surge Testing Methodology

When performing a surge test:

- The equipment is disconnected and safely isolated

- Test leads are connected to the winding terminals

- High-voltage pulses are applied sequentially to each phase

- Resulting waveforms are captured and displayed

- Waveforms are compared between phases or against baseline readings

- Deviations in waveform patterns indicate potential faults

The key methodological difference is that Megger testing measures steady-state resistance, while surge testing analyzes dynamic waveform responses to rapid voltage pulses.

Voltage Levels and Test Duration

Megger Test Voltage and Duration

- Voltage Levels: Typically 500V to 5000V DC depending on equipment rating

- Test Duration: Usually 60 seconds for spot readings, up to 10 minutes for polarization index

- Voltage Application: Gradual ramp-up to test voltage, sustained for the test period

- Frequency: DC (0 Hz)

Surge Test Voltage and Duration

- Voltage Levels: Can range from 1kV to 40kV depending on equipment rating

- Test Duration: Microseconds per pulse, with multiple pulses applied

- Voltage Application: Rapid rise-time pulses (typically <1.5 μs)

- Frequency: High-frequency components in the pulse

The significant difference in voltage application—steady DC versus rapid pulses—creates fundamentally different stresses on the insulation system, revealing different types of weaknesses.

Interpretation of Results

Megger Test Interpretation

Megger test results are interpreted through:

- Absolute resistance values (typically in megohms)

- Minimum acceptable values based on IEEE standards

- Polarization index (PI) ratio

- Dielectric absorption ratio (DAR)

- Trending of values over time

- Temperature correction factors

Good Results Typically Show:

- High resistance values (hundreds of megohms to gigohms)

- PI values greater than 2.0

- Consistent readings between phases

- Stable or improving trends over time

Surge Test Interpretation

Surge test results are interpreted through:

- Waveform shape and characteristics

- Pulse-to-pulse consistency

- Phase-to-phase comparison

- Comparison to baseline or reference waveforms

- Frequency response analysis

- Error area ratio calculations

Good Results Typically Show:

- Consistent, overlapping waveforms between phases

- Smooth sinusoidal patterns

- Low error area ratios

- No shifts in frequency or amplitude

- No indication of flashover or breakdown

The interpretation approach differs dramatically—Megger tests yield numerical values for comparison, while surge tests primarily rely on waveform pattern analysis.

Explore our high-quality digital surge testers

Equipment and Complexity

Megger Test Equipment

- Cost Range: $1,000 to $10,000 for quality instruments

- Portability: Generally highly portable

- Complexity: Relatively simple to operate and interpret

- Data Storage: Basic data logging in modern instruments

- Additional Features: Temperature correction, timed tests, automatic PI calculation

Surge Test Equipment

- Cost Range: $5,000 to $50,000+ for comprehensive systems

- Portability: Less portable, especially for high-voltage units

- Complexity: More complex operation and interpretation

- Data Storage: Advanced waveform capture and comparison

- Additional Features: Multiple test types, automated analysis, reference waveform libraries

The equipment complexity difference reflects the fundamental difference in testing purpose—Megger testers perform relatively straightforward resistance measurements, while surge testers must generate high-voltage pulses and perform sophisticated waveform analysis.

When to Use Each Test

When to Use Megger Testing

Megger testing is most appropriate when:

- Performing routine maintenance checks

- After exposure to wet conditions

- After long storage periods

- When ground insulation issues are suspected

- As part of regular preventative maintenance

- Following motor cleaning or servicing

- After transportation or environmental changes

- Before commissioning new or repaired equipment

When to Use Surge Testing

Surge testing is most appropriate when:

- Evaluating winding condition comprehensively

- During motor manufacturing quality control

- After motor rewinding or repair

- When turn-to-turn faults are suspected

- After severe electrical events (lightning, surges)

- Before accepting repaired equipment

- When investigating unexplained motor performance issues

- As part of enhanced predictive maintenance programs

The timing difference reflects their complementary nature—Megger testing is often used more frequently and routinely, while surge testing is typically performed at critical junctures or when more comprehensive analysis is needed.

Complementary Testing Approach

Rather than viewing Megger and surge testing as alternatives, modern maintenance programs recognize them as complementary tools:

- Sequential Testing: Megger testing first to verify ground insulation, followed by surge testing for turn insulation

- Risk-Based Application: Higher-value or critical equipment receives both tests

- Trigger-Based Testing: Anomalies in Megger results may trigger surge testing

- Comprehensive Baseline: Both tests establish baseline readings for new equipment

- Integrated Analysis: Results from both tests provide complete insulation assessment

This complementary approach ensures complete winding evaluation—ground insulation and turn insulation—providing maximum confidence in equipment condition.

Learn about digital surge tester applications

Safety Considerations

Megger Testing Safety

Key safety considerations for Megger testing include:

- Equipment must be completely de-energized and locked out

- Discharge windings before and after testing

- Observe proper grounding procedures

- Use appropriately rated test leads

- Consider stored energy in capacitive equipment

- Maintain safe clearances during testing

Surge Testing Safety

Surge testing requires additional safety precautions:

- Complete lockout/tagout procedures

- Secured testing area with restricted access

- Proper grounding of all equipment

- Appropriate personal protective equipment

- Verification of no explosive atmospheres

- Proper discharge procedures before and after testing

- Higher voltage rating requirements for test leads

- Awareness of potential for audible discharges

The safety requirements for both tests reflect their voltage levels and application methods—with surge testing generally requiring additional precautions due to the higher voltages and rapid discharge characteristics.

Common Testing Mistakes

Common Megger Testing Mistakes

Frequent errors in Megger testing include:

- Incorrect test voltage selection: Using too high or too low voltage

- Insufficient test duration: Not allowing adequate time for absorption current

- Missing temperature correction: Failing to account for temperature effects

- Improper connections: Poor contact or unintended paths to ground

- Incorrect interpretation: Misunderstanding deteriorating trends

- Overlooking humidity effects: Not considering environmental conditions

Common Surge Testing Mistakes

Frequent errors in surge testing include:

- Incorrect voltage selection: Not using appropriate test voltage for the equipment

- Inadequate comparison: Failing to compare phases or reference waveforms

- Misinterpreting noise: Confusing electrical noise with actual defects

- Improper connections: Poor lead connections affecting waveform quality

- Insufficient baseline data: No reference for comparison

- Overlooking partial discharge indicators: Missing early warning signs

The common mistakes in both testing methodologies highlight their different technical requirements and interpretation challenges, further underlining their distinct but complementary roles.

Modern Advancements in Testing Technology

Megger Testing Advancements

Recent improvements in insulation resistance testing include:

- Computer interfaces with advanced trending analysis

- Automatic temperature correction

- Wireless data transmission to maintenance systems

- Integration with predictive maintenance software

- Enhanced noise rejection technology

- Battery-powered units with extended field operation

Surge Testing Advancements

Modern surge testing technology offers:

- Digital wave form capture and analysis

- Automatic error area ratio calculation

- Cloud storage of reference waveforms

- AI-assisted interpretation

- Combined test capabilities (surge, resistance, impedance)

- Touch-screen interfaces with guided test procedures

The VM5K-VM6K Digital Surge Tester represents the latest in surge testing technology, offering advanced features that simplify testing and improve diagnostic capabilities.

Conclusion

Megger and surge testing serve distinctly different purposes in a comprehensive motor testing program. Megger testing evaluates the critical ground wall insulation, while surge testing assesses the equally important turn-to-turn insulation integrity. Neither test can substitute for the other—they work together to provide a complete picture of winding insulation health.

Understanding the differences in what they detect, how they operate, and how to interpret results enables maintenance professionals to apply these powerful diagnostic tools effectively. The optimal approach integrates both testing methodologies into a comprehensive maintenance strategy, providing maximum protection against unexpected winding failures.

For motor maintenance excellence, remember this essential principle: Megger testing and surge testing are complementary, not competitive, diagnostic tools. Together, they form the foundation of effective electrical insulation assessment.

For more information on selecting and utilizing the right testing equipment for your specific needs, contact Vivid Metrawatt customer support or explore our comprehensive range of testing solutions.

This technical comparison is provided for general information purposes only. Always refer to specific test equipment manufacturer documentation for detailed operating procedures and safety requirements.