Have you ever wondered how electronic devices manage to weather sudden voltage spikes without failing? It’s a fascinating process that involves a critical piece of equipment known as a surge tester. Surge testers are invaluable tools in the realm of electrical engineering and play a pivotal role in ensuring the durability and safety of electronic components used across various industries. Let’s delve into what surge testers are, their significance, and how they are applied in real-world scenarios.

To put it simply, a surge tester is a device that evaluates the robustness of electrical components by applying controlled voltage surges. Imagine a stress test for electronics designed to reveal any weak spots that might otherwise cause device failures. Through this process, surge testers help in identifying potential fault points so they can be addressed early, thus extending the lifespan and reliability of electronic products.

The origins of surge testing can be traced back to the early innovations in electric motors and power systems. Initially, engineers struggled to prevent motor failures caused by insulation breakdowns. This necessity led to the development of primitive surge testing methods. As technology advanced, so did our ability to conduct surge tests more accurately and safely, transforming these tests into a staple of modern electrical testing protocols.

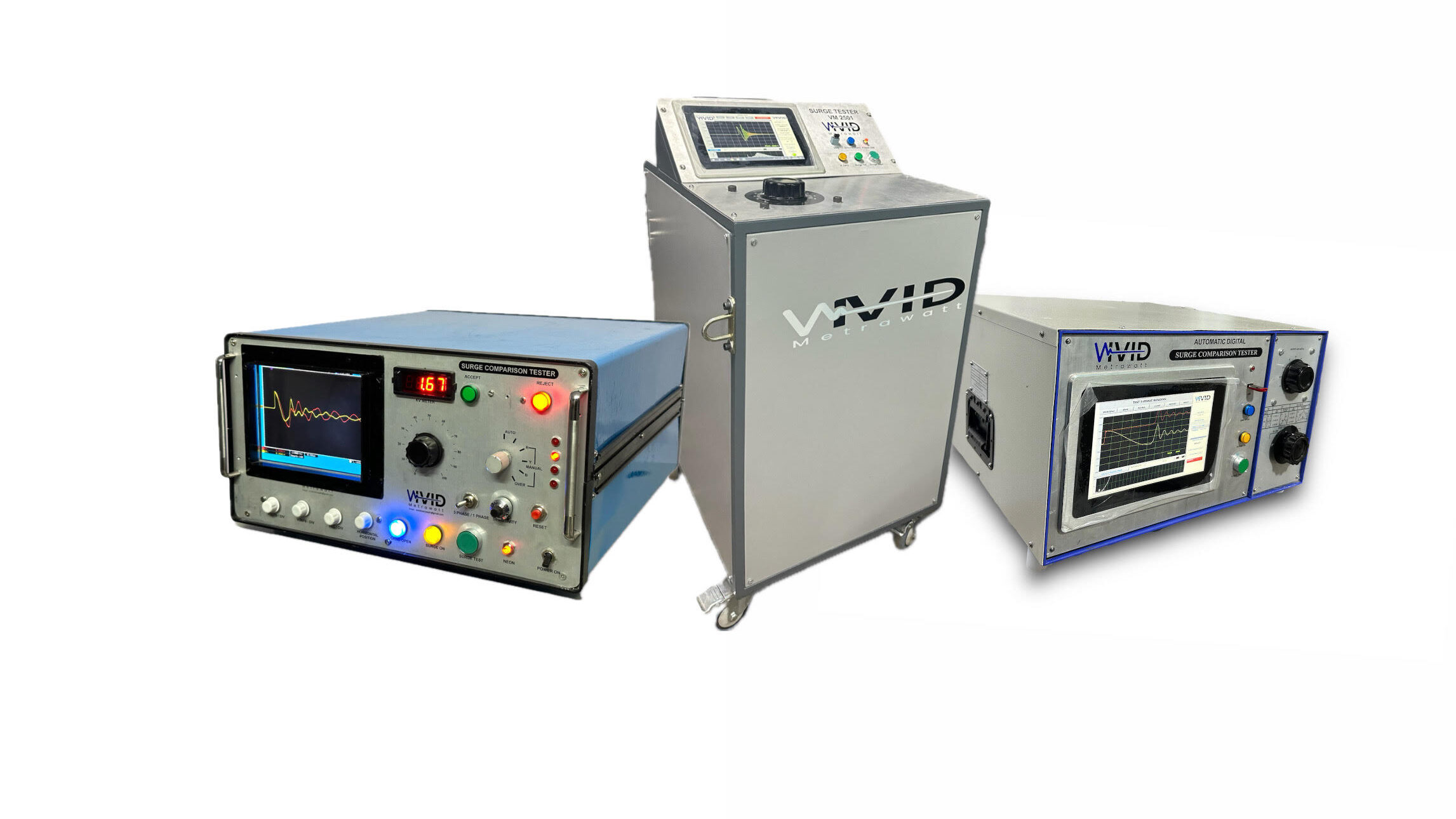

Surge testers come in various types to suit different testing requirements. The primary categories include digital and analog models. Digital surge testers are known for their precision and advanced functionalities, often providing more user-friendly interfaces. Analog models, while more traditional, offer reliability in straightforward applications. Furthermore, surge testers can be portable or benchtop models, each catering to specific uses—the former being ideal for on-site checks, while the latter is best suited for thorough laboratory analyses.

Surge testers are composed of several integral parts that work together to perform accurate assessments. They include:

Each of these components plays a role in providing a comprehensive assessment of the electronic component’s ability to withstand unexpected voltage surges.

Consider surge testing as a preventive health checkup for electronics. It is an essential step in product development and validation, especially for systems where reliability is critical. By simulating real-world electrical surges, manufacturers can identify potential failures and rectify them before they head to market. This process not only enhances the longevity of the devices but also bolsters their safety and reliability in operation, crucial for industries like aerospace, automotive, and consumer electronics.

Surge testers are pivotal across various sectors:

The most significant benefit of surge testing lies in its ability to preemptively detect insulation faults and other potential issues. By catching these errors early, manufacturers can avert costly failures and significant downtime. This proactive approach not only fortifies products against operational mishaps but also fortifies consumer trust through improved product reliability and reduced warranty claims.

Nevertheless, surge testing does not come without its challenges. If not conducted with care, the high voltages involved could potentially damage the component being tested, especially if the testing parameters are not correctly configured. Additionally, the costs associated with carrying out comprehensive surge tests can add up, particularly impacting smaller firms with tight budgets.

Adherence to standards such as IEC 61000-4-5 is vital when conducting surge testing. These standards outline the appropriate test protocols and waveform characteristics to ensure consistent and reliable results across different testing conditions. Compliance with these standards is not just about meeting regulatory requirements; it’s about ensuring that products can perform safely and reliably under stress.

Implementing surge testing effectively involves several practices:

By following these guidelines, manufacturers can ensure their products are not only compliant but also robustly designed against electrical faults.

Looking at practical applications, consider the case of an automotive company that integrated surge testing into its quality control systems. By routinely conducting surge tests, it was able to detect wiring faults early, thus drastically reducing the incidence of vehicle recalls due to electrical issues. This proactive approach resulted in the enhancement of product reliability, improvement of consumer trust, and reduction of warranty claims, showcasing the tangible benefits of integrating surge testing into manufacturing processes.

As electronic systems continue to become more complex, the importance of precise and reliable surge testing is expected to grow. Future trends may involve the integration of artificial intelligence into surge testing practices, allowing for more sophisticated data analysis and earlier identification of potential faults. This progression could transform how companies approach product testing, leading to more comprehensive and efficient testing capabilities.

To sum up, surge testers are an essential part of ensuring the durability and safety of electronic systems. By identifying weaknesses before they lead to failures, surge testing helps maintain the performance and reliability of electronic components across diverse industries. Staying updated with technological advancements and adhering to best practices in surge testing will prove critical for maintaining the integrity and reliability of electronic devices in the fast-evolving technology landscape.